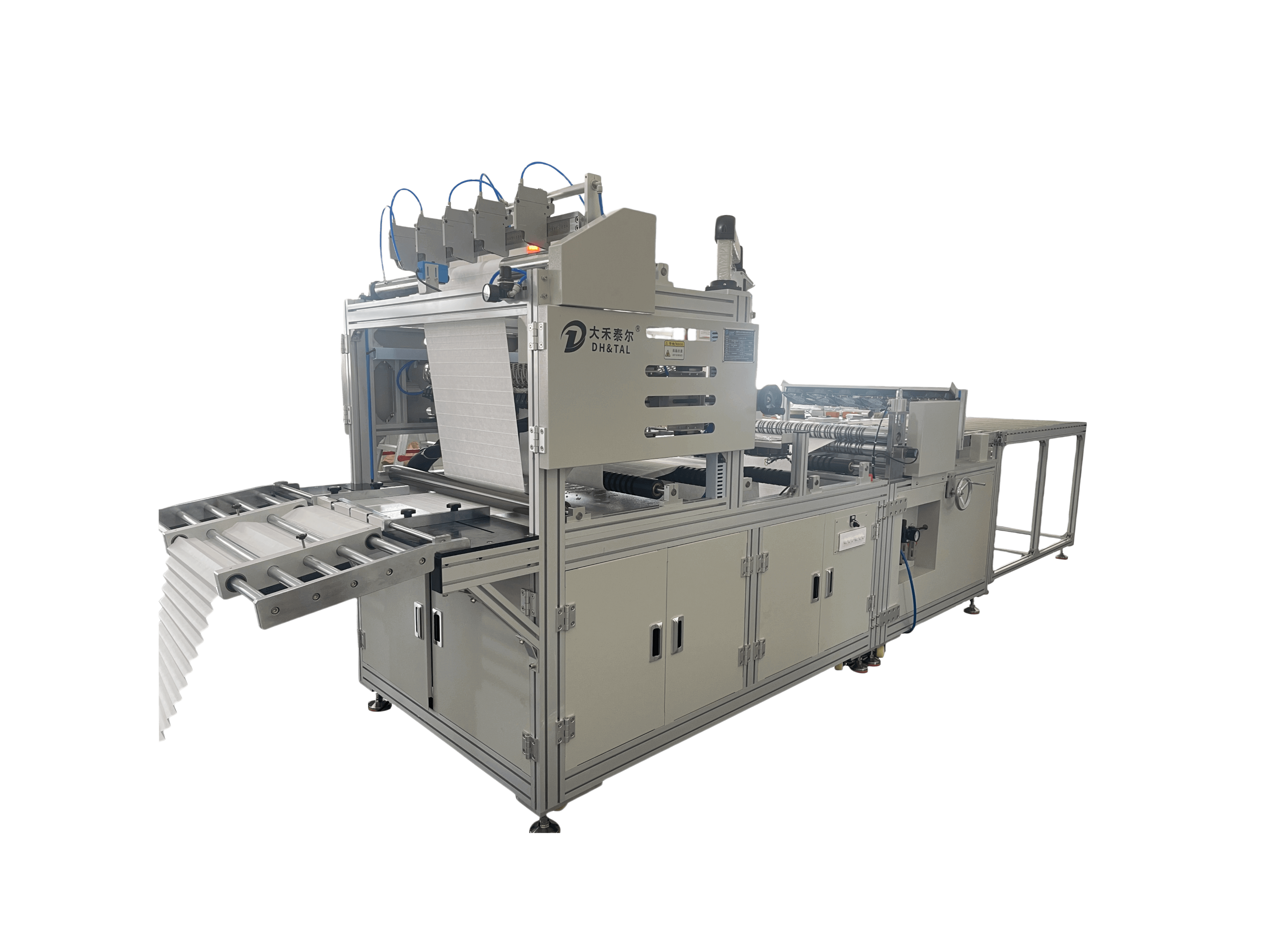

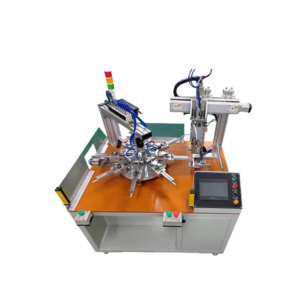

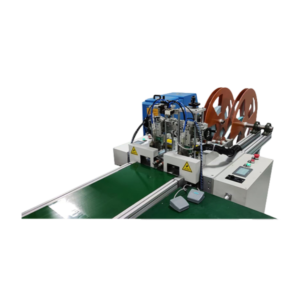

Fully automatic glue injection production line

The fully automatic glue injection production line adopts a sturdy aluminum profile frame and provides four main glue injection modes: continuous glue injection, staggered glue injection, breakpoint glue injection, and point glue injection. It is also equipped with an independent cooling fan, adjustable nozzle and precision slitting knife to ensure high stability, efficiency and flexibility to meet various filter manufacturing needs.

Equipment parameters:

Dahe Intelligence can provide customized services for fully automatic glue injection production lines with non-standard specifications and sizes to better meet the production needs of different customers.

| Parameters of the fully automatic glue injection production line: | |

|---|---|

| Equipment size: | L5.3m × W1.25m × H1.8m |

| Maximum width of product: | 850mm |

| Adjustable folding height range: | 6–80mm |

| Glue machine capacity: | 60L |

| Glue injection gun head: | 2×26 |

| Number of glue strips: | 2×26, 52 in total |

| Glue line spacing: | 25.4mm |

| Glue injection width: | 660.4mm |

| Production efficiency: | 0–20m/min |

| Machine power supply voltage: | 220V/50Hz |

| Total machine efficiency: | 18KW |

| Equipment efficiency: | 3KW |

| Glue machine efficiency: | 15KW |

| Glue machine power supply voltage: | 380V/50Hz |

| Working air pressure: | 0.6MPa |

Equipment advantages:

The main body of the fully automatic glue injection production line is a firm and beautiful aluminum profile frame structure. It has four primary functions: continuous glue injection, dislocation glue injection, broken glue injection, and dot glue injection.

- Three-color indicator lights are divided into three sections: glue injection, wave receiving, and motionless roller. Each section is an independent frame, which is convenient for transportation and disassembly.

- The feed is equipped with a lack of material shutdown sensor and two side blocks to prevent the material from going off.

- A pressure plate counterweight presses the material to increase the tension. Based on the actual material thickness, the pressure plate tension can be increased or reduced for greater stability.

- A slitting knife is installed before glue injection and can be selected based on specific needs. The slitting knife is equipped with a scale for quick knife alignment.

- Each gun nozzle is independently adjustable, switchable, and can be turned on/off on the display.

- After glue injection, there are two sets of cooling fans on the upper and lower sides, and the wind speed of each set is independently adjustable. After receiving the wave, a set of cooling fans on the upper and lower sides is also independently adjustable.

- The upper and lower needles of the wave-receiving machine can be adjusted up and down and forward and backward to the required folding height by adjusting a hand wheel.

- The non-powered roller has a hinge connected to the wave-receiving material output, solving the problem of product glue line disconnection.

Equipment use:

The filter glue application machine is widely used in industries that require precise glue control, stable feeding, and continuous adhesive lines. It provides reliable bonding performance and supports various filter and material processing applications, including:

Automotive Filters: Ideal for producing air filters, oil filters, and fuel filters, ensuring accurate glue application for tight sealing and durable bonding.

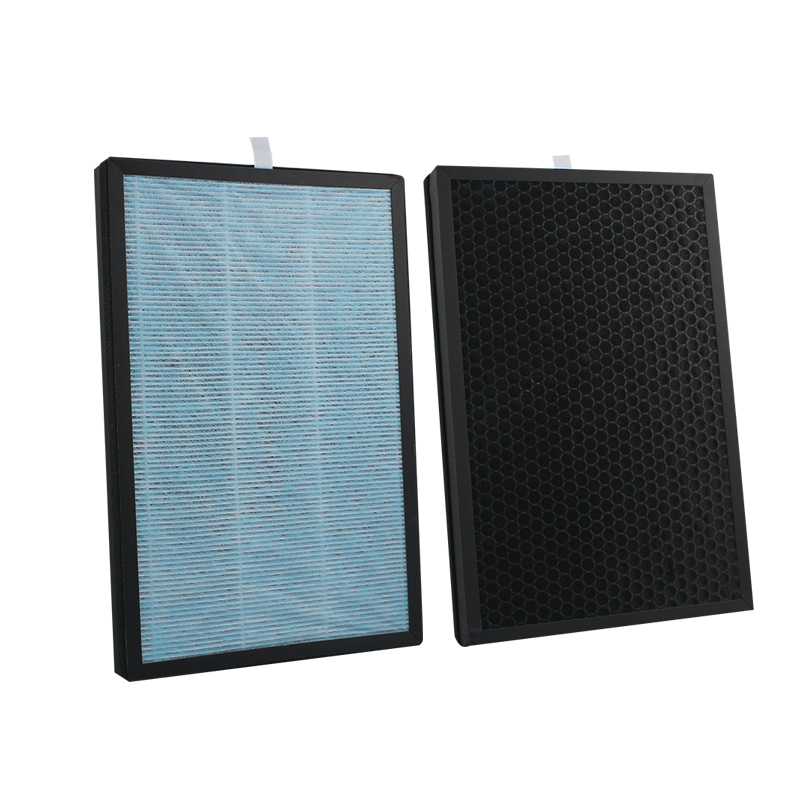

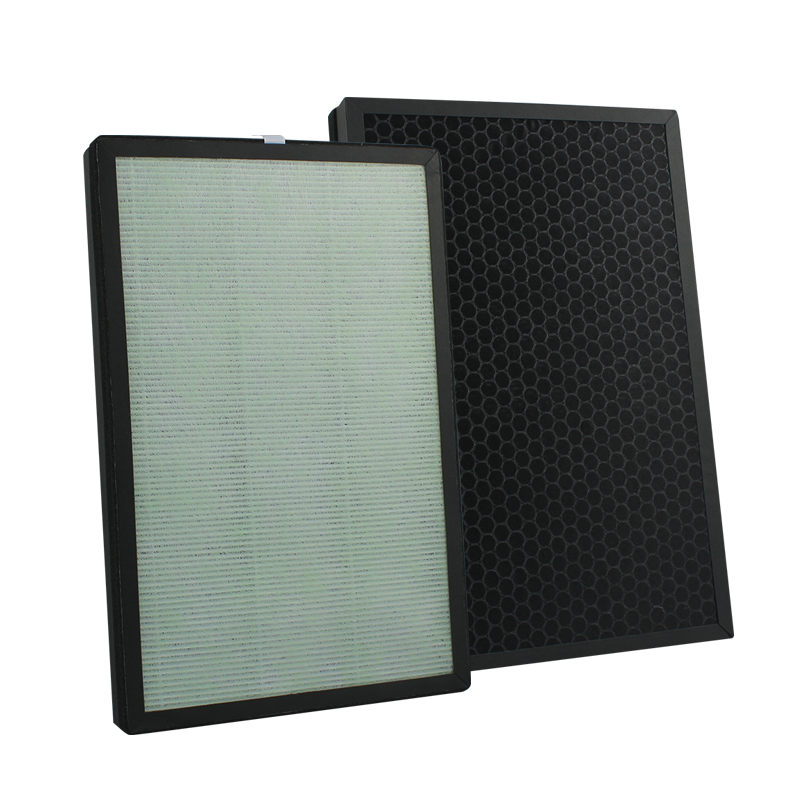

Industrial and HVAC Filters: Used in the manufacturing of industrial dust filters, air conditioning filters, and air purifier cartridges, maintaining consistent glue lines and preventing disconnection.

Household Appliance Filters: Suitable for vacuum cleaner filters, water purifier cartridges, and other consumer filtration products requiring precise adhesive control.

Medical and Laboratory Filtration Products: Applicable for assembling medical-grade filter media and lab filtration materials that demand high precision and clean operation.

Paper and Packaging Materials: Supports corrugated paper, honeycomb board, and other multi-layer paper bonding processes that require uniform glue lines and stable feeding.

Electronics and Environmental Equipment: Used for bonding and sealing components in electronic dust filters, environmental protection filters, and air treatment devices.

With its independent glue injection system, adjustable fan cooling, and modular structure, this machine ensures stable performance across a wide range of production lines.

Customer site pictures:

Professional filter equipment manufacturer

Please leave your contact information and our professional business consultants will provide you with corresponding solutions and quotations and answer your questions.

Customer Reviews

“This pleating machine has revolutionized our production process. We can now meet high demand and produce 40% faster without sacrificing quality or efficiency.”

James Murray

“The Paper pleating machine has increased the precision and efficiency of our production process. Our filter performance has improved significantly, which is critical to our customers.”

David Green

Join Our Newsletter

Related Products

Related products

-

Household air purification filter

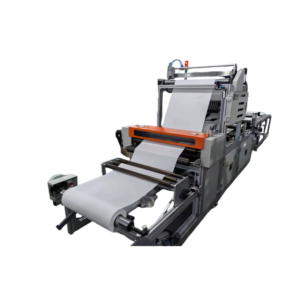

Fully automatic fiberglass origami glue injection production line

Rated 0 out of 5Read more -

Household air purification filter

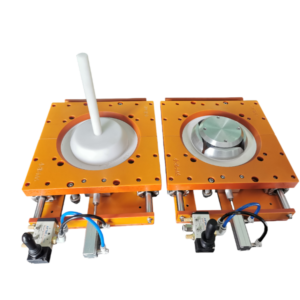

Automatic edge strip scraper–double station

Rated 0 out of 5Read more

Contact

- Building 3, Simin Industrial Zone, No. 56 Xiaoxiang Wenming Road, Wanjiang District, Dongguan City

- +86 13560883391

- tableliu@126.com

- WhatsApp:+8613560883391

SHORTCUT LINKS

- Home

- Product

- About Us

- Video Case

- Contact Us

- Blog

PRODUCTS

- Automobile air conditioning filter production

- Household air purification filter

- Vacuum cleaner and sweeping robot filter

- Hot melt adhesive machine

- Precision machinery parts processing

Contact us

© Copyright 2024 Technical Support: Lezhan