Precision machinery parts processing

Precision machinery parts processing

Dahe Intelligent has a precision mechanical parts processing division that can produce high-precision, high-rigidity processed parts to better cooperate with filter production.

Product Categories

-

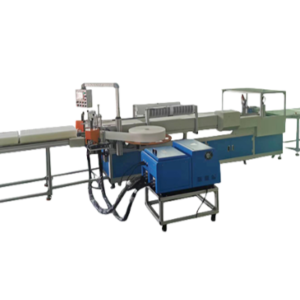

Household air purification filter

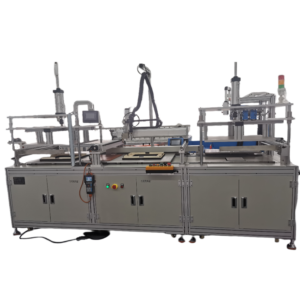

Continuous welting machine on both sides

Rated 0 out of 5Read more

-1024x683.jpg)

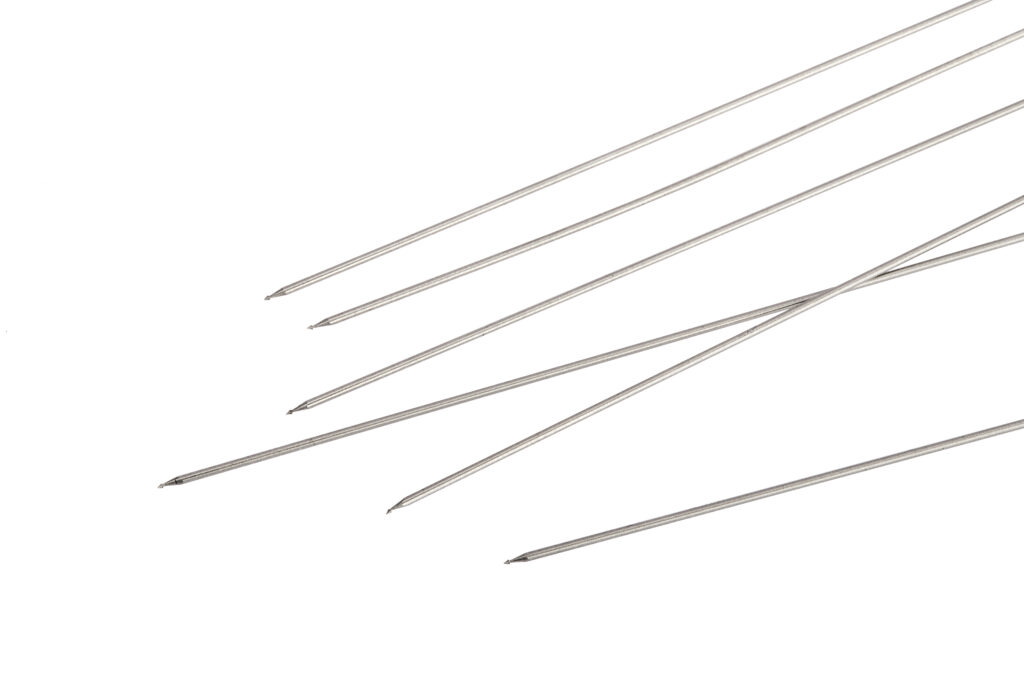

Medical stainless steel processing

Stainless steel turning parts

加工-2-1024x683.jpg)

Copper parts processing

Stainless steel lathe small steel parts

加工-1024x683.jpg)

Filter end cap assembly fixture

加工-1024x683.jpg)

Aluminum parts processing

Carbonized shaft

加工-1-1024x683.jpg)

Stainless steel product processing

加工-1024x683.jpg)

Titanium alloy processing

加工-1024x683.jpg)

Aluminum disc processing

加工-1024x683.jpg)

Stainless steel product processing

Tungsten-molybdenum electrode sheet processing

Essential and important question for you

Yes, our equipment is designed to handle a variety of filter materials, including woven wire mesh, non-woven fabrics, synthetic fibers, paper, activated carbon, and more. We also offer customization options to meet specific material requirements.

The production capacity of our equipment varies depending on the model and type of filter being produced. We offer solutions ranging from small-scale production units to high-volume machines capable of producing large numbers of filters per hour. Please contact us for specific capacity details based on your needs.

Of course. We specialize in providing customized solutions for your unique production needs. Whether you require a specific size, material, or special features, our research and development team can work with you to design equipment to your exact specifications.

The lead time depends on the complexity of the equipment and the current order volume. Typically, standard models have shorter lead times, while custom solutions may take longer. We will provide an estimated delivery timeline when you place your order.

Contact

- Building 3, Simin Industrial Zone, No. 56 Xiaoxiang Wenming Road, Wanjiang District, Dongguan City

- +86 13560883391

- tableliu@126.com

- WhatsApp:+8613560883391

SHORTCUT LINKS

- Home

- Product

- About us

- Video Case

- Contact Us

- Blog

PRODUCTS

- Automobile air conditioning filter production

- Household air purification filter

- Vacuum cleaner and sweeping robot filter

- Hot melt adhesive machine

- Precision machinery parts processing

Contact us

© Copyright 2024 Technical Support: Lezhan