Filter screen four welt production lines are essential for manufacturing high-quality filter components in automotive air conditioning and HVAC industries. However, traditional production methods often face capacity challenges due to the need for manual intervention, inconsistent product sizes, and slow cycle times. Operators usually have difficulty completing repetitive tasks such as placing folded filter elements on molds, adjusting wedging parameters, and managing material flow. These inefficiencies lead to bottlenecks, limited production, and increased labor costs. To solve this problem, companies need advanced automation strategies to eliminate processes that rely on manual labor. Dahe Intelligent’s innovative approach combines a fixture return system, fully automatic control, and robotic precision to simplify operations. The filter screen four welt production line can bring higher production capacity by rethinking the workflow without sacrificing quality.

Fixture return system: completely changing the material flow of the filter screen four welt production line

The integrated fixture return system is one of the most impactful upgrades in the modernization of the filter four-patch production line. Because the traditional setup requires workers to manually transfer the folded and cut filter elements between workstations, resulting in delays and changes. Dahe’s intelligent design automates this process: after workers place the pre-treated filter elements on the dedicated fixtures, the system uses a closed-loop conveyor to return these fixtures to the starting point. This eliminates downtime caused by fixture shortages or manual retrieval.

The fixture reflow method ensures continuous material flow, reduces human error, and maintains consistent positioning for downstream processes such as wedging and cutting. By synchronizing the movement of the fixture with the rhythm of production, manufacturers can increase line efficiency by up to 40%. This approach is efficient for high-mix, low-volume production, where fast fixture adjustments are critical.

Fully automatic control: filter screen four welt production line combines precision and flexibility

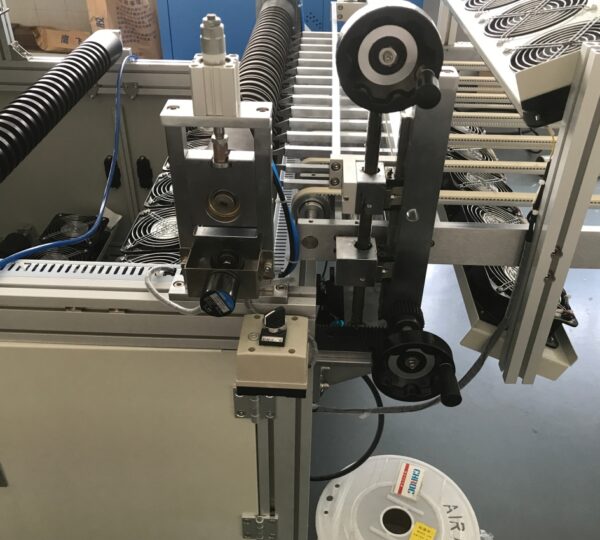

Automation is the key to solving the capacity problem of the filter four-side production line. Dahe Intelligent’s solution adopts a fully automatic control system driven by Mitsubishi PLC, and the servo drive controls every link of the production process. At the same time, the operator no longer needs to manually adjust the wedge size, cutting angle or production speed – these parameters are pre-programmed and automatically executed.

For example, the PLC system dynamically adjusts the wedging pressure based on real-time feedback from sensors to ensure perfect alignment even with different material thicknesses. Similarly, servo-driven actuators control the cutting blade with micron-level accuracy to minimize waste. This level of automation also enables the filter screen four welt production line to adapt to different customer specifications.

Reduce manual adjustments with adaptive dimensional control.

Product variations often force manufacturers to stop production for manual recalibration, which erodes capacity. Dahe Intelligent’s filter screen four welt production line solves this problem with adaptive dimensional control. The system automatically adapts to filter element size, thickness, or material type changes using servo-driven actuators and real-time monitoring. For example, if a batch of filter elements is slightly wider, sensors detect this deviation and instruct the wedging mechanism to expand accordingly – all without operator intervention. The same is valid for cutting angles: the system recalculates the blade trajectory based on product size, ensuring accuracy for all units.

Quantifying the capacity improvement of the filter screen four welt production line

Dahe Intelligent’s four filter screen welt production lines can improve production capacity across the board: shorten cycle time, and the automatic wedging and cutting processes can reduce cycle time by 35-50%. Save labor costs and reduce manual intervention, which can reduce labor requirements by up to 60%. At the same time, the error rate is also reduced, and precision automation can reduce the defect rate to <0.5%. In addition, the production line can quickly adapt to future upgrades, such as AI-driven predictive maintenance. By adopting fixture reflow, full automation and adaptive control, the company was able to solve capacity issues and future-proof its operations.

Comprehensively improve the capacity of the production line

The capacity challenges of the filter screen four-edge production line can be solved through intelligent automation, precision engineering and workflow optimization. In addition, integrating fixture reflow system, Mitsubishi servo and other functions can create a seamless, high-speed manufacturing process and a production line that can adapt to dynamic production needs.