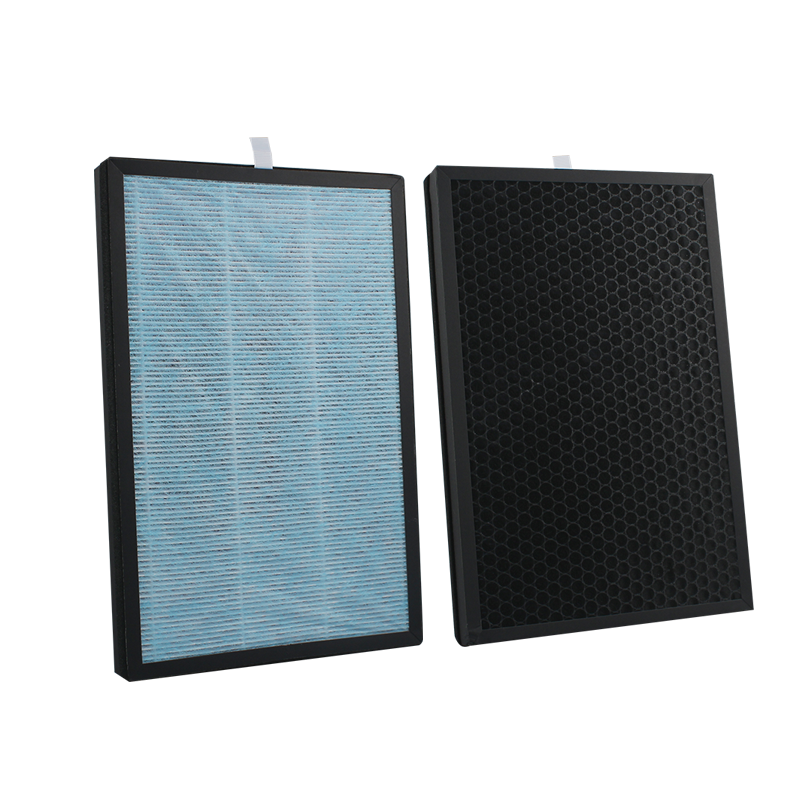

To reduce the scrap rate of a four-welt filter screen production line, you must first identify every potential source of defects and then ensure that the scrap rate can be reduced through powerful automation and precise control. Scrap usually comes from pleat misalignment, adhesive overflow, dimensional deviation or filter material tearing. These failure modes not only waste materials but also reduce production speed. The four-welt filter screen production line manufactured by Dahe Intelligent adopts fully automatic control and complete analog servo drive control. The product size can be fully adjusted automatically.

These problems are solved by integrating real-time monitoring, closed-loop feedback, and recipe-driven settings. An adjustable stroke scraper gun is used in the scraper part to ensure that there is no glue leakage and accurate glue cutting. At the same time, by automatically detecting deviations and adjusting machine parameters in real time, these systems can prevent the production of unqualified parts.

Four-welt filter screen production line with fully automatic control

To eliminate the inconsistency caused by manual intervention and improve the degree of automation in the fully automatic four-welt filter screen production line, when the operator selects the required filter shape, the system retrieves the correct filter media width, pleat spacing, and adhesive parameters from the central recipe database. Then, automatic tensioners, servo-driven feeders, and programmable logic controllers (PLCs) coordinate the various stations, including slitting, pleating, welding, cutting, and gluing, to keep production moving in sync. Traditional welt screen lines now allow batch switching in minutes, eliminating hours of downtime and manual recalibration. This level of automation not only significantly reduces scrap caused by setup errors but also enables filter manufacturers to respond quickly to new orders.

More precise control with fully analog servo drives

In addition to fully automated production, the four-pass hemming line also uses a four-welt line. Unlike stepper motors that move in fixed increments, analog servo motors continuously adjust torque and speed based on real-time feedback from encoders. This means that the pleating rollers can maintain a consistent pleat depth, even if the media hardness changes due to moisture fluctuations or material batch differences. Similarly, the rotating cutting and spot welding axes can achieve sub-millimeter repeatability at high speeds, virtually eliminating size-related scrap. In addition, the high dynamic response of the servo drives and their built-in overload protection ensure gentle handling of delicate media without compromising cycle time, combining precision and output in one energy-efficient package.

Automatic adjustment of wedge size and cutting angle

Maintaining the correct wedge height and cutting angle in production prevents pleat collapse and ensures acceptable trim edge quality. In a four-welt screen line, laser triangulation or vision-based sensors measure pleat height and cutting geometry in real-time. Suppose the system detects a change, for example, a 0.2 mm offset in wedge depth. In that case, the PLC immediately commands the positioning motor to fine-tune the wedge carriage or adjust the cutting blade direction. This feedback loop maintains production speed while ensuring dimensional accuracy without stopping the line. This self-correcting capability not only reduces scrap but also extends tool life by preventing repeated mistakes and saving material and maintenance costs.

Precision glue application with adjustable stroke doctor gun

Adhesive application errors are a significant contributor to the scrap rate of four-welt lines. To address this problem, we use an adjustable stroke doctor gun that can accurately meter the glue and deliver the glue at the exact pleat root angle. At the same time, programmable stroke length, pressure, and dwell time ensure that each filter receives the same adhesive coverage, eliminating over-dosage and gaps. Additionally, the gun’s fast response time synchronizes with line speed changes to prevent build-up or stringing during acceleration and deceleration. This level of control ensures a clean coating line and a strong bond, minimizing mess and scrap due to glue defects and eliminating the need for expensive downtime for cleanup. You can further enhance consistency by fine-tuning the glue rheology and adjusting the barrel temperature to accommodate various filter media and adhesive formulations.

Process quality monitoring of the four-welt filter screen production line

High-speed cameras and laser sensors integrated into the four-welt screen line capture detailed images of every pleat, seam and glue bead. The integrated vision software analyzes each element based on preset pleat spacing, seam alignment and adhesive width tolerances. Any unit that is out of range triggers an automatic rejection mechanism, preventing it from continuing downstream production. At the same time, a real-time dashboard displays scrap indicators and trend lines, allowing operators and engineers to identify ongoing problems and proactively address them. This continuous feedback loop not only keeps scrap rates low but also cultivates a culture of constant improvement. Additionally, the data collected can be fed into machine learning models to predict and prevent future deviations.

Achieving Ultra-Low Scrap Rates

To reduce scrap rates, we strike a balance between automation, precision drives, real-time monitoring, and rigorous maintenance. By leveraging fully automated control systems, complete analog servo accuracy, automatic sizing, and fine-tuned adhesive application, we can achieve mass production consistency on four-welt screen lines. When you combine online quality checks with a rigorous maintenance regimen, you can further reduce scrap rates.