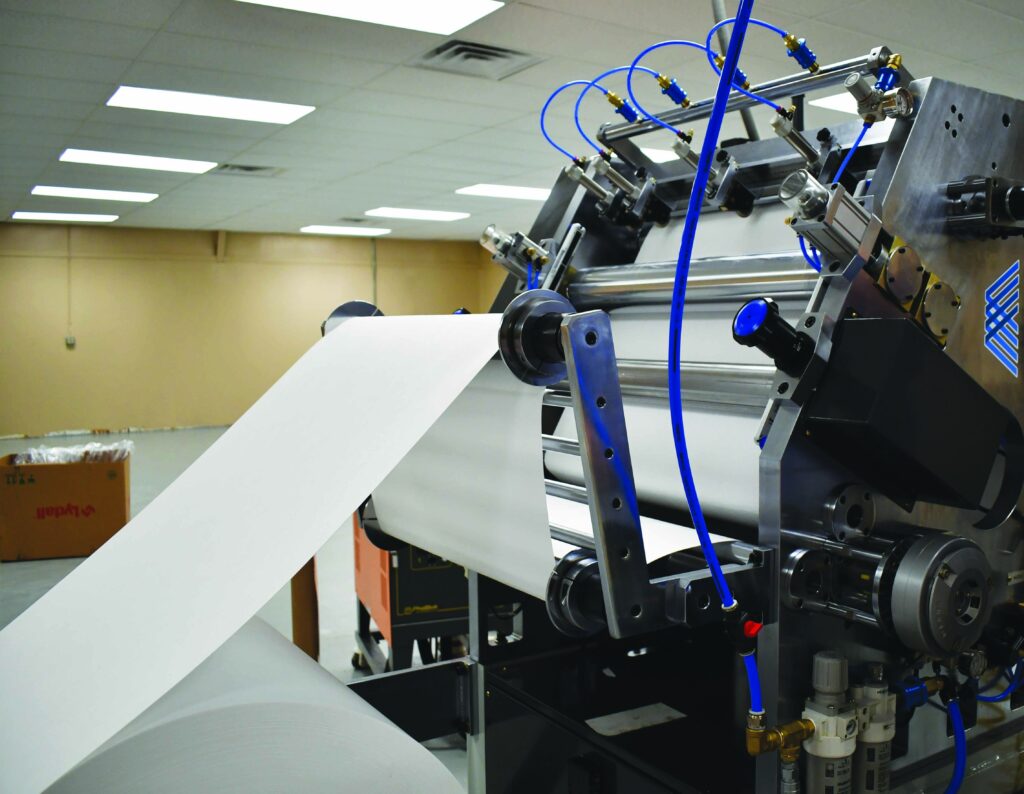

Manufacturers in filtration, HVAC, and clean-air production have been upgrading their pleating lines at a rapid pace. One major driver is the need for higher accuracy and repeatability. Traditional mechanical systems struggle to maintain consistent pleat geometry as production speeds increase. This inconsistency affects airflow resistance and filter efficiency. PLC-Controlled Pleating Equipment solves these issues by giving operators precise control over every motion. The system manages pleat depth, pitch, tension, and timing in real time. As a result, manufacturers gain stable output and better alignment across long production runs. This reliability is essential for HEPA and high-efficiency HVAC filters, where slight variations can result in measurable reductions in filtration performance.

Higher Precision for Modern Filter Designs

Modern filters use more complex media than ever before. Synthetic papers, melt-blown composites, and glass microfiber layers require careful handling. Even a minor stretch or compression can reduce efficiency. Mechanical pleating machines lack the sensitivity needed for today’s materials.

PLC-driven systems deliver accurate pleat formation by synchronizing servo motors and control modules. This allows uniform pleat depth even at high speed. Manufacturers report a 20–30% reduction in material waste after upgrading to PLC-controlled systems (based on published case studies from large HVAC filter plants). This consistency also reduces downstream defects during gluing and curing, ultimately improving production throughput.

Faster Changeovers and Greater Flexibility

Global production schedules are becoming more demanding. Manufacturers often switch between HEPA filters, automotive filters, and HVAC sizes within the same shift. Manual adjustments slow down production and increase downtime.

PLC-Controlled Pleating Equipment streamlines changeovers with stored recipes and automated adjustments. Operators select predefined settings for pleat height, pitch, and material type. The machine configures itself in minutes. This flexibility helps plants respond to shifting market demands without sacrificing efficiency or quality. For high-mix, mid-volume operations, this changeover speed can significantly reduce production bottlenecks.

Lower Operating Costs Through Automation

Labor costs continue to rise, and manufacturers need automation to stay competitive. PLC-controlled systems reduce the number of operators required per line. They also minimize training time because most key functions are automated.

Energy use is another cost factor. Servo-controlled pleating Equipment consumes less energy compared to older mechanical systems. Research from several equipment suppliers shows energy savings of 10–15% in full-year operation due to optimized servo motion. Lower wear on mechanical parts further reduces maintenance costs, which adds up across multiple production lines.

Improved Quality Control and Real-Time Monitoring

Quality standards for filtration products have become more stringent. HEPA filter production must comply with ISO 29463 or EN 1822. HVAC filter production tests follow ASHRAE 52.2. These certifications demand consistent pleat geometry, airflow resistance, and mechanical strength.

PLC-Controlled Pleating Equipment integrates with sensors, cameras, and feedback systems. These devices monitor pleat formation in real time and make micro-corrections during operation. Operators see key production data on digital dashboards. This real-time visibility reduces defects, improves traceability, and ensures that each batch meets required performance levels.

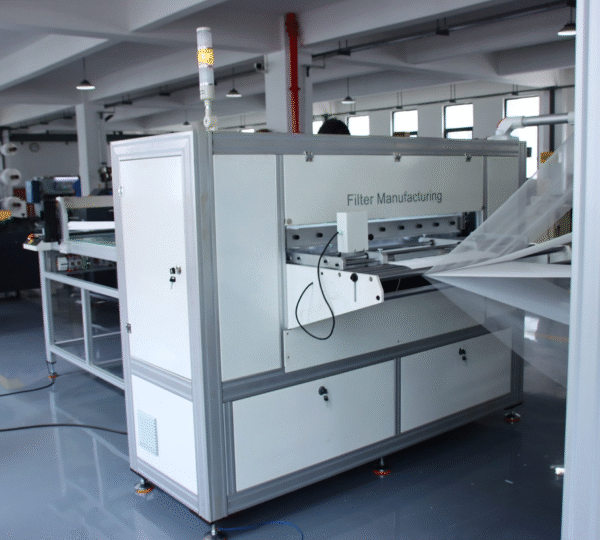

Better Integration With Automated Production Lines

Manufacturers aim to streamline entire production lines, not just pleating sections. PLC-based systems are designed for integration. They connect easily with pre-feeding units, gluing stations, curing ovens, and cutting modules.

This connectivity supports Industry 4.0 goals. Production data flows to a central system for analysis. Maintenance teams receive early warnings when components show signs of wear. Plants running large HVAC or HEPA filter lines rely on this integration to maintain continuous operation and reduce downtime. The shift toward smart factories naturally supports the adoption of PLC-controlled machinery.

Real-World Adoption Examples

Large HVAC filter producers in the U.S. and Europe have publicly discussed their shift to PLC-driven machinery. For example, several ASHRAE-certified filter plants reported smoother production when switching from manual pleating to servo-controlled systems. They achieved lower rejection rates and more predictable output.

Another example comes from an Asian HEPA filter manufacturer that upgraded its pleating lines to PLC control to meet rising demand in semiconductor cleanrooms. The company reported improved pleat alignment and reduced manual intervention. These public cases show a clear trend: manufacturers gain measurable benefits from modernizing their pleating processes.

Why PLC-Controlled Pleating Equipment Is Becoming the New Standard

More manufacturers are switching to PLC-controlled pleating equipment because it offers precision, flexibility, reduced waste, and improved product quality. These systems support modern materials, integrate seamlessly into automated lines, and provide real-time data for quality control.

As filtration standards grow stricter and production demands rise, manufacturers need Equipment that can keep pace. PLC-controlled systems deliver consistent results, lower costs, and greater reliability. Choosing this technology is not just a technical upgrade—it is a strategic decision that protects long-term competitiveness in a demanding industry.