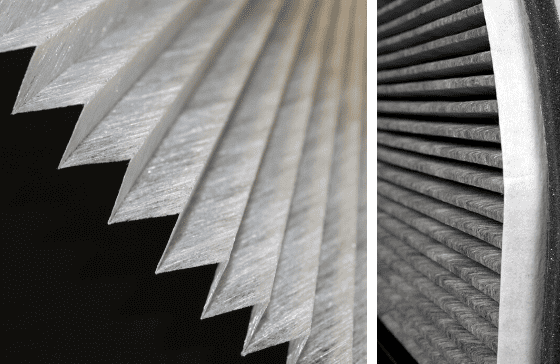

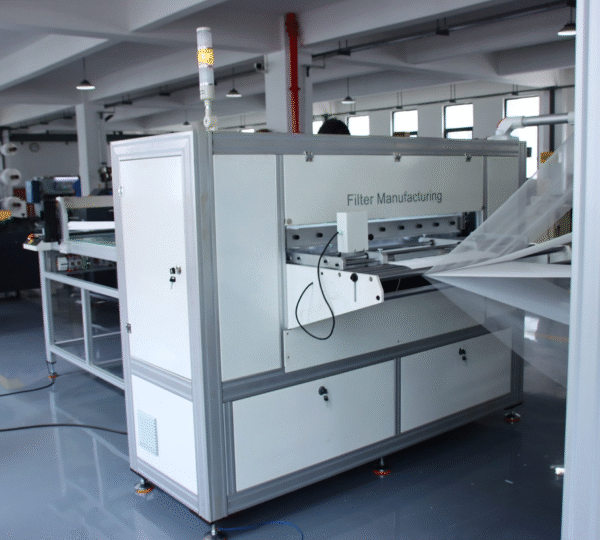

Manufacturers today demand absolute precision and repeatability in filter production. Traditional pleating systems often rely on mechanical adjustments, which can drift over time and result in inconsistent pleat height or pitch. In contrast, PLC-controlled pleating equipment offers unparalleled consistency. The programmable logic controller (PLC) regulates every motion—roller speed, heating time, and folding pressure—with millisecond accuracy. This digital precision translates into uniform pleats and tighter tolerances. For example, a leading automotive filter producer reported a 25% reduction in defective pleats after upgrading to PLC-controlled systems. The result? Less material waste and higher customer satisfaction.

Real-Time Monitoring and Error Detection

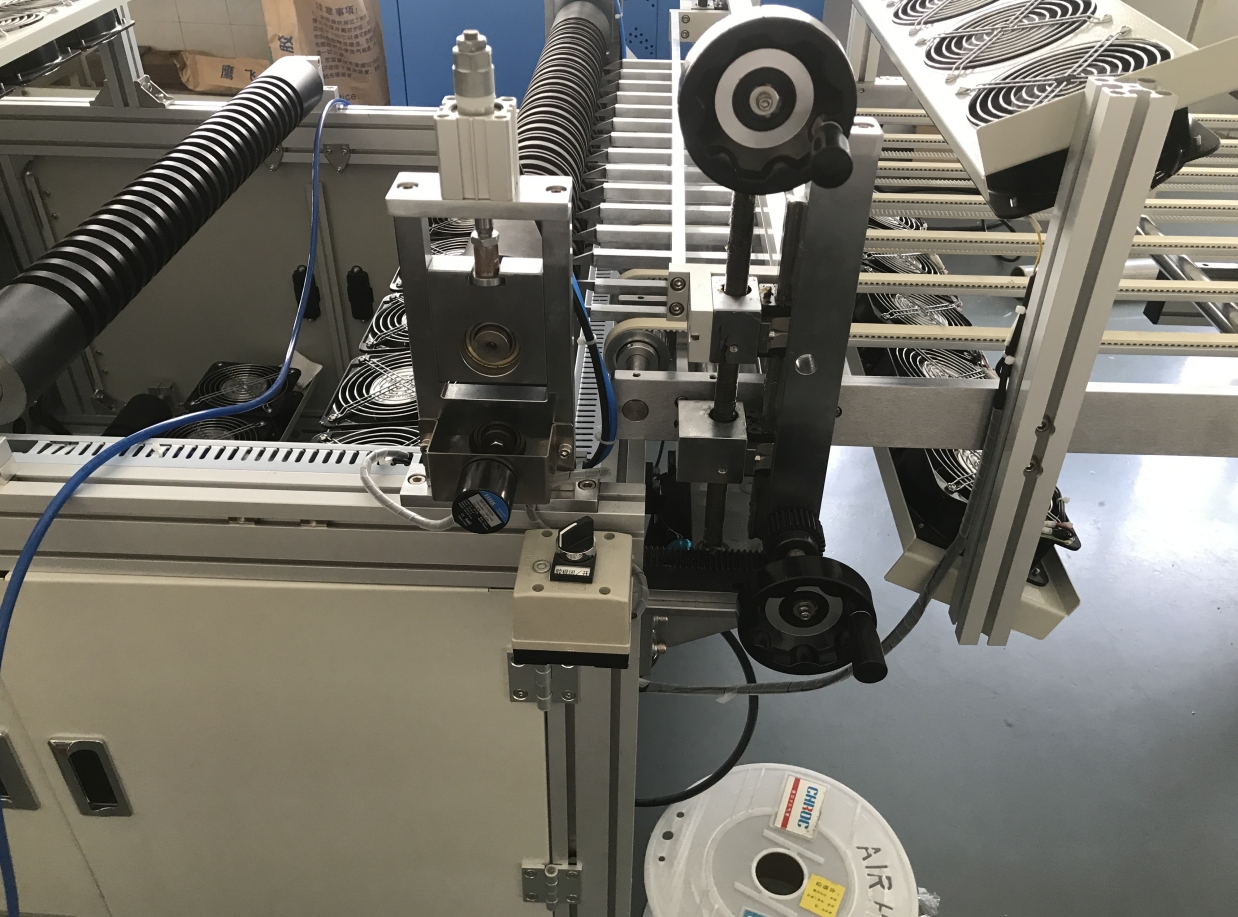

One of the biggest game changers for modern pleating lines is real-time data. With PLC control, operators can monitor temperature, pressure, and cycle time through an intuitive touchscreen interface. When deviations occur, the system automatically triggers alarms or halts production to prevent defective output. Traditional systems rarely provide this kind of intelligence; they rely on operator observation and manual correction. By integrating PLCs, manufacturers reduce downtime caused by unnoticed malfunctions. A medium-sized air filter plant in Germany reported a 15% boost in uptime after switching to PLC-based pleating equipment—thanks to early fault detection and automatic diagnostics.

Flexible Production and Quick Changeovers

In markets with high product variation, flexibility matters as much as speed. PLC-controlled systems allow operators to switch between different pleat patterns, filter media, or glue application modes with just a few taps. Recipes can be saved and recalled instantly, eliminating the need for lengthy mechanical recalibration. Traditional systems, on the other hand, require manual adjustments that may take hours. With PLC automation, changeovers that once consumed half a shift now take minutes. This agility helps manufacturers respond quickly to customer demands and smaller production batches without sacrificing quality.

Improved Energy Efficiency

Traditional pleating machines often run at fixed speeds and constant heating levels, wasting energy during idle times. PLC-controlled pleating equipment dynamically adjusts energy consumption according to load requirements. The PLC modulates heater temperature and motor torque in real time, minimizing unnecessary power draw. According to a 2024 industry report from MarketsandMarkets, energy-efficient automation can lower overall operating costs in filter manufacturing by up to 20%. For facilities running multiple pleating lines, these savings quickly add up to significant annual cost reductions.

Enhanced Safety and Operator Control

Safety standards in manufacturing have tightened globally. Traditional systems depend on mechanical limit switches and manual emergency stops, which can delay response times in fast-moving operations. PLC-controlled setups integrate electronic safety interlocks and automatic shutdown logic. If a sensor detects abnormal tension or overheating, the system reacts instantly—preventing damage or injury. Moreover, user interfaces display clear warnings and step-by-step troubleshooting instructions. This not only keeps workers safer but also reduces training time for new operators.

Seamless Integration with Smart Manufacturing

The rise of Industry 4.0 has changed how factories operate. Modern PLC-controlled pleating equipment supports Ethernet, Modbus, or Profinet communication, allowing it to connect with factory networks and production management systems. Manufacturers can analyze performance data remotely, schedule predictive maintenance, and synchronize multiple machines for coordinated operation. Traditional systems, built on analog controls, cannot provide this level of connectivity. By upgrading to digital control, manufacturers position themselves for future integration with smart factories and automated inspection systems.

Long-Term Reliability and Reduced Maintenance

Mechanical cam systems in older pleating equipment wear out over time and require frequent recalibration. PLC-based systems use fewer mechanical linkages and more electronic control, resulting in longer maintenance intervals. Diagnostic software can even predict when a component—such as a servo or heater—approaches failure. As a result, unplanned downtime drops dramatically. One Asian filter manufacturer documented a 30% reduction in maintenance costs within the first year of adopting PLC-controlled systems. Over the long term, the investment pays back not just in production quality but also in reduced operational hassle.

Future of PLC-Controlled Pleating Equipment

Choosing PLC-controlled pleating equipments is more than a technical upgrade—it’s a strategic decision. It gives manufacturers digital control, consistency, and adaptability that traditional systems can’t match. As global demand for precision filters grows—from HVAC to medical and automotive industries—the need for efficient, intelligent production becomes even more critical. PLC-based automation empowers factories to deliver higher output, lower waste, and stronger reliability. For manufacturers aiming to stay competitive in a fast-evolving market, the choice is clear: the future fits perfectly with PLC control.