Filter pleating changes a flat sheet of media into a high-surface-area pack. That change lets designers fit a lot more media into a small volume. As a result, pleated filters can lower face velocity, raise dirt-holding capacity, and balance efficiency against pressure drop. A well-designed pleat, therefore, drives both performance and operating costs. Below, I explain the mechanics, common trade-offs, and practical rules you can use when specifying or designing pleated filters.

How pleats increase effective surface area

Pleating multiplies the media area inside a fixed housing. In turn, the filtration face velocity drops for the same volumetric flow. Lower face velocity improves particle capture by diffusion and interception for small particles. Consequently, pleated cartridges deliver higher initial efficiency than equivalent flat-sheet assemblies. Designers rely on this simple geometric gain to hit target efficiency without oversizing housings.

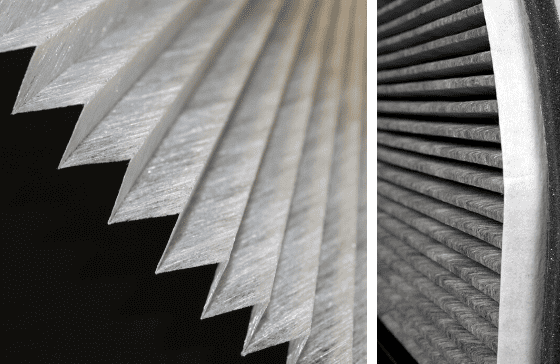

Pleat geometry: height, pitch, and ratio matter

Pleat height and pitch (spacing) set the pleat ratio. This ratio controls how air flows across a pleat and into the downstream side. Studies show that there is an optimal pleat ratio for minimizing the initial pressure drop at a fixed flow rate. Too shallow or too tall pleats both raise resistance. Therefore, select the pleat height and pitch that match your media permeability and intended face velocity. Experimentally derived ratios and models guide that choice.

Pleat packing density — not more is always better.

Adding pleats increases area — but only up to a point. If pleats sit too close, they form narrow channels and high local velocities. This increases the pressure drop and can reduce the effective filtration area when the pleats come into contact with each other. Research modeling pleat packing density finds a “just right” number of pleats for a given cartridge geometry. In practice, manufacturers balance packing density against media strength and pleat-support structure. Over-packed pleats can actually worsen performance and shorten service life.

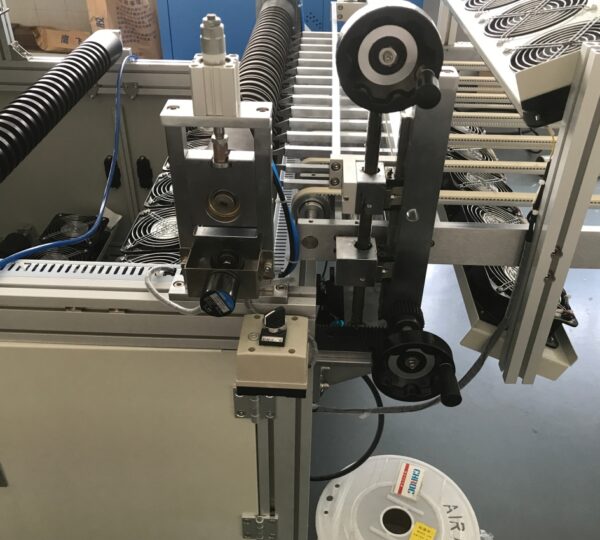

The support structure and pleat stability have a significant influence on long-term performance

Pleats must stay open under flow, handling, and dust load. Therefore, designers add support grids, scrim layers, or adhesive bonds at pleat roots. Without proper support, pleat deformation causes local channeling and early pressure-rise. Additionally, support elements contribute to system resistance, so they must be optimized accordingly. Good pleat-support design maintains even airflow and extends the time between change-outs.

Dust loading, deposition patterns, and maintenance intervals

Pleat tips and valleys collect dust in predictable ways. Early in life, deposition spreads fairly evenly. Over time, though, particle agglomeration near pleat tips can form “particle walls” that block downstream flow paths. When that happens, the filter’s effective filtration area drops and the pressure climb accelerates. Therefore, the pleat design should consider loading behavior and maintenance windows. Models and recent simulations visualize these deposit patterns, allowing you to predict service life.

Material choice, media permeability, and electrostatic effects

Media type sets the baseline resistance and capture efficiency. For high-efficiency applications, such as HEPA, pleats are delicate and closely spaced because the media uses very low-permeability fibers and often features an electrostatic charge. For coarse prefilters, larger pleats and coarser media perform better. Thus, match the pleat depth and count to media permeability. In addition, some presses lose electrostatic charge with humidity—so factor environmental conditions into pleat and media choices.

Design trade-offs for airflow, efficiency, and total cost

Design always balances three key factors: desired capture efficiency, acceptable pressure drop (and fan energy consumption), and cost per operating hour. Filter Pleating directly influences all three. For example, deeper pleats can reduce pressure drop and energy use, but they may complicate manufacturing and raise cost. Conversely, tighter pleats can boost initial efficiency but increase fan power and reduce life expectancy. Use simulation tools and bench tests to quantify these trade-offs before choosing a nominal Filter Pleating geometry.

Practical rules of thumb for effective Filter Pleating

First, target a face velocity that matches your media’s optimal range. Second, avoid over-packing pleats—leave enough spacing to prevent contact under load. Third, add proper support or scrim to avoid deformation. Fourth, select a pleat geometry that is consistent with the expected dust-loading patterns. Finally, validate with both clean-air pressure-drop tests and dust-loading cycles to confirm life and energy use. Following these steps ensures the pleat design maximizes airflow and filtration efficiency.