What to Look for When Purchasing an Air Filter Pleating Machine

Air filter pleating machines are crucial to determining the efficiency, quality, and profitability of your filter manufacturing process. Whether you’re looking to boost production capacity, improve pleating precision, or ensure consistent filter quality, choosing the right machine is essential. These machines automate the pleating process, cutting labor costs and reducing human error. This leads to more consistent and higher-quality filters. A well-selected air filter pleating machine also improves production efficiency and reduces downtime. It streamlines operations, optimizes material use, and helps your business meet rising market demands. As air filtration standards tighten, investing in the right technology ensures you remain competitive while upholding the highest product standards.

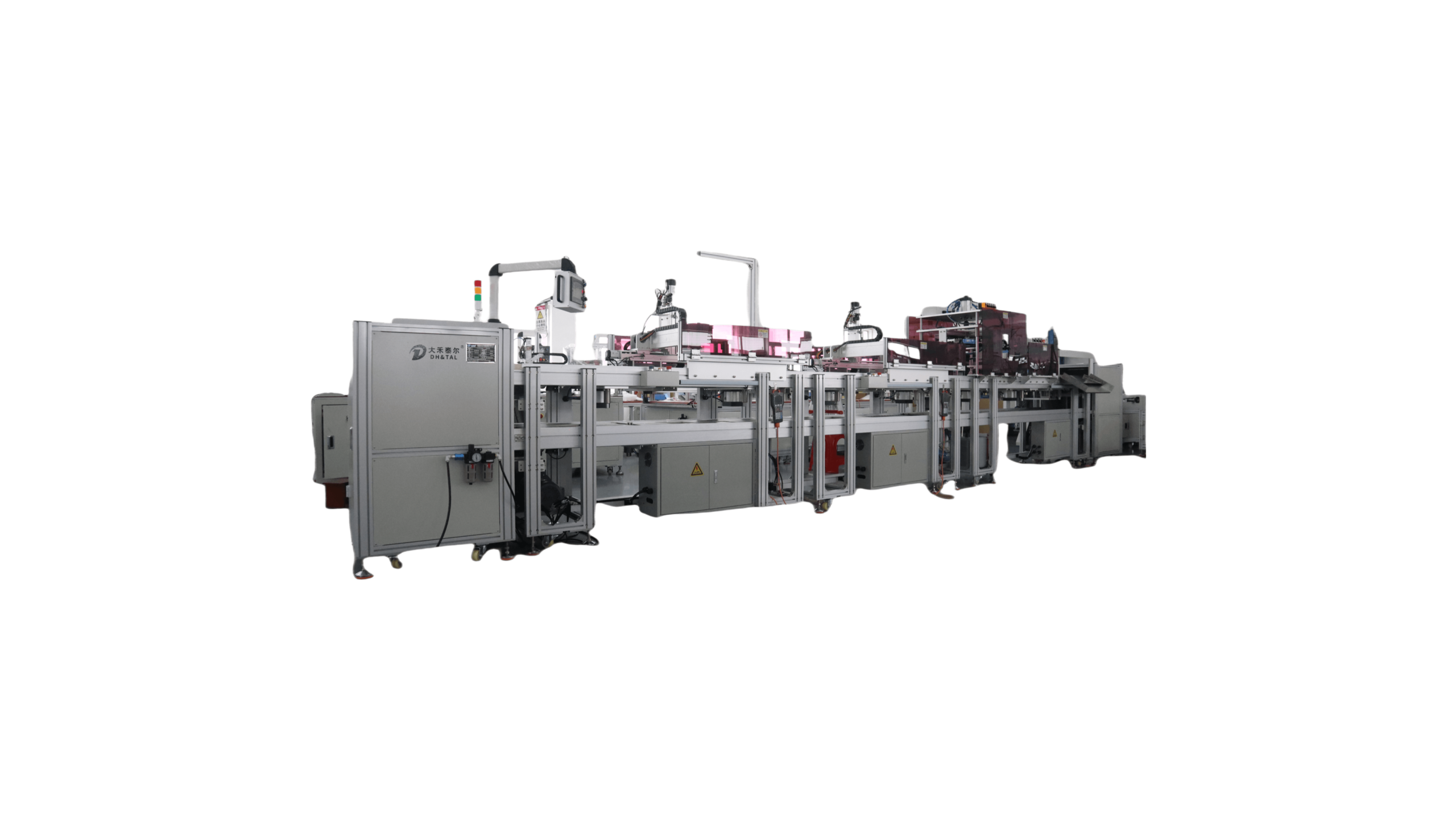

Air Filter Pleating Machine: Choosing the Right Model and Technology

The first consideration when purchasing an air filter pleating machine or filter folding system is determining the right model for your specific needs. Advanced machines, such as the DHHP-700, are designed for high-efficiency applications and feature cutting-edge features that optimize production. This particular model offers automatic feeding, tension control, and servo-driven mechanisms, which can increase both production speed and precision. You should assess your production requirements—whether you need a fully automated system or a more basic, semi-automated machine—based on factors like production volume, filter material type, and product complexity.

Production Capacity and Speed: Maximizing Efficiency

Another key factor to consider when purchasing anFilter Folding System is its production capacity. Machines like the DHHP-700, with high levels of automation, can handle large volumes of material with minimal downtime. The speed at which the machine operates will directly affect your output and efficiency. Look for machines with adjustable pleating speeds, enabling you to balance throughput and product quality. This flexibility is essential when adapting to varying production demands, whether you’re manufacturing high volumes of standard filters or specialized filters that require more intricate pleating.

Air Filter Pleating Machine: Material Compatibility and Flexibility

Filter Folding Systems are engineered to accommodate a variety of filter materials, such as fiberglass, polyester, and other synthetic media, each requiring specific handling to maintain their integrity and performance. When selecting an air filter pleating machine, ensure it is compatible with the materials you use in your production process. For instance, fiberglass, commonly used in high-efficiency filters, requires precise control to prevent material breakage and achieve consistent pleating. Machines like the DHHP-700 are well-suited for processing such materials, offering specialized features to maintain pleat quality. Furthermore, the machine’s ability to handle a range of filter sizes and thicknesses is crucial. This versatility allows manufacturers to adjust to different customer needs and produce a wide range of air filters, making it easier to meet both standard and custom filter requirements. By selecting a machine that supports a broad range of materials and sizes, manufacturers can enhance production flexibility and meet diverse market demands with ease.

Precision and Quality Control Features

The precision of your Filter Folding System is crucial to ensuring high-quality output. Machines like the DHHP-700 feature servo-controlled mechanisms that maintain precise tension and speed, guaranteeing uniform pleat height and consistent product quality. Look for features such as adjustable pleat height, precise cutting mechanisms, and integrated quality control systems that can detect errors during production. These features not only enhance the quality of the final product but also reduce the likelihood of defects and waste during manufacturing.

Ease of Operation and Maintenance

The ease of use and maintenance of your Filter Folding System is another essential factor to consider. Machines with intuitive touchscreen interfaces, such as the DHHP-700, simplify operations by enabling operators to easily adjust settings and monitor production. Additionally, a user-friendly design can reduce the training time required for new staff members. When it comes to maintenance, look for machines with self-diagnostic features and easy-to-access components to minimize downtime and ensure long-term machine reliability.

Energy Efficiency and Operating Costs

In today’s competitive manufacturing environment, minimizing operating costs is a top priority. Look for air filter pleating machines that prioritize energy efficiency. These machines can significantly lower electricity consumption and reduce operating costs over time. For example, the DHHP-700 uses both electric power and compressed air, making it a cost-effective choice for large-scale production. Also, consider the machine’s durability and the cost of consumables like adhesive and glue. These factors can impact your overall production expenses.

Air Filter Pleating Machine: Installation, Setup, and Support

Finally, consider the installation process, setup, and the level of customer support provided by the manufacturer. A good air filter pleating machine supplier will provide comprehensive installation services, including assistance with site preparation and machine calibration. Machines like the DHHP-700 come with clear installation guidelines, ensuring a smooth setup process. Additionally, check the warranty, after-sales support, and spare parts availability to ensure you are well-supported throughout the machine’s lifespan.