What Sets a High-Performance Filter Paper Pleating Machine Apart?

Filter paper pleating machines are essential in industries that rely on filtration systems, where efficiency, precision, and cost-effectiveness drive success. A high-performance filter paper pleating machine is crucial for producing high-quality filters. But what makes one stand out from the rest?

Advanced Pleating Technology in the Filter Paper Machine

A filter paper pleating machine plays a crucial role in creating uniform pleats that enhance the filter’s structure and improve filtration efficiency. High-performance machines use advanced technology to ensure consistent pleating, reduce clogging, and optimize performance. Many modern machines are servo-driven, offering precise control over pleat formation. Additionally, adaptive control systems automatically adjust settings for different filter materials, ensuring efficient production. These advancements enable manufacturers to achieve higher-quality filters with less waste, thereby improving both speed and cost-effectiveness.

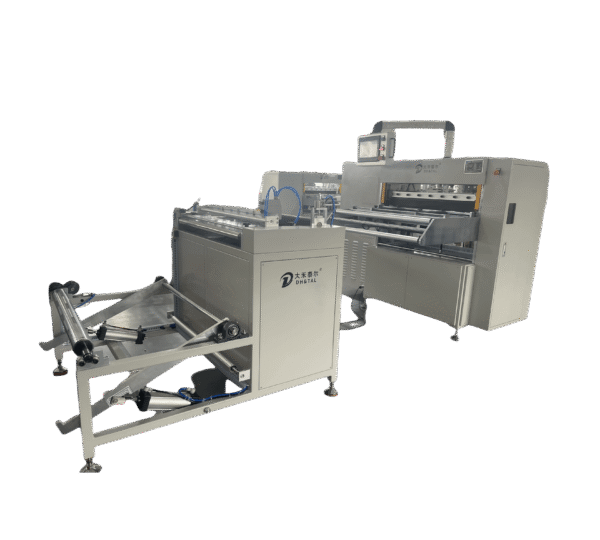

Filter paper pleating machine for precision and consistent quality

Precision is essential in filter paper pleating. A high-performance filter paper pleating device is carefully engineered for smooth, consistent operation. The machine’s frame and components must work in harmony to reduce vibrations and noise. This level of engineering ensures that each pleat is perfectly aligned. Optical sensors and laser-guided systems monitor the pleating process, detecting any discrepancies and maintaining high quality throughout production.

Automation and Efficiency in Filter Pleating Devices

Automation is a significant advantage of high-performance filter paper pleating machines. It reduces the need for manual labor, reducing human error and improving overall efficiency. These machines feature automated systems that handle crucial tasks such as loading, unloading, and adjusting pleating parameters like depth, width, and tension. Computerized controls enable precise adjustments, ensuring consistent pleating quality across a range of filter materials. By automating these processes, manufacturers can not only speed up production but also reduce material waste and ensure uniformity in every batch.

Furthermore, real-time automated monitoring systems continuously track machine performance, alerting operators to any issues before they lead to costly downtime or defects. This proactive approach helps minimize disruptions, improve throughput, and ultimately increase production efficiency. The combination of faster operations, reduced errors, and early issue detection ensures that high-performance pleating machines deliver both operational and cost efficiency.

Flexibility and Customisation for Diverse Applications

Flexibility is a critical feature of a high-performance filter paper pleating machine. Different filtration applications often require varying pleat sizes, depths, and materials. A top-tier pleating machine allows users to adjust pleat depth, width, and angle, providing the versatility needed for a wide range of filter types. This customization enables manufacturers to produce filters for a wide range of industries, from air and water filtration to automotive and pharmaceutical applications. The ability to adjust these settings allows work with different filter media, such as synthetic fabrics, fiberglass, and cellulose, ensuring optimal pleating for each material. Additionally, high-performance machines enable quick changes between production runs, improving efficiency and reducing setup time. This level of flexibility allows manufacturers to meet specific customer requirements while maintaining high-quality production standards across various filter applications, making the machine a valuable asset for businesses with diverse filtration needs.

Durability and Longevity of Filter Pleating Machines

Durability is crucial when investing in a filter paper pleating machine. High-performance machines are made from sturdy materials like stainless steel and are designed to withstand long production runs. These materials resist wear, corrosion, and other forms of damage, ensuring reliable operation. The machines are also easy to maintain, with accessible components for cleaning and part replacement. Self-diagnostic tools help operators detect issues early, reducing downtime and extending the machine’s lifespan. This durability ensures businesses maximize their investment by minimizing maintenance costs and production interruptions.

Filter paper pleating machine: Cost efficiency and ROI

A high-performance filter paper pleating machine is not only efficient but also cost-effective. Its advanced design helps reduce material waste, energy consumption, and labor costs. The integration of automation minimizes the need for manual intervention, streamlining production and reducing human error. Automated systems can adjust settings quickly and accurately, enhancing overall operational efficiency. Furthermore, the machine’s efficient design helps minimize downtime, ensuring that production runs smoothly without delays. These machines are built for high-speed performance, which significantly increases throughput and reduces production time. Over time, the savings on operational costs—such as lower energy use, reduced waste, and fewer labor hours—translate into a substantial return on investment. By improving productivity while lowering costs, these pleating machines provide long-term value, enabling businesses to scale operations without compromising quality.

Advanced Safety Features for Operators

Safety is a top priority in high-performance filter paper pleating machines. These machines come with safety guards, emergency stop buttons, and automatic shut-off systems to protect operators. Sensors continuously monitor performance and halt operations if any malfunction occurs, preventing damage and ensuring smooth operation. Advanced diagnostic tools also alert operators to maintenance needs, reducing downtime and enhancing safety. With these safety features, manufacturers can provide a secure working environment and protect both personnel and equipment.