As the demand for clean air continues to grow across industries, the need for high-quality air filters has never been greater. Air filter manufacturers constantly look for ways to improve their production processes to meet these demands while maintaining cost-effectiveness and high standards. To achieve this goal, selecting the right air filter production line equipment for producing air filters is critical. This includes investing in advanced machinery such as HEPA filter paper slitting machines, automatic glue injection lines, and paper pleating machines to increase production speed, precision, and consistency. This article will explore the best air filter production line equipment solutions for air filter manufacturers. From fully automatic systems to dedicated machines, we will discuss how each piece of equipment plays a vital role in production.

High-efficiency filter paper slitting machines in air filter production line equipment

HEPA filter paper slitting machines are key in air filter production line equipment, especially for manufacturers producing HEPA filters. HEPA filters are designed to capture fine particles and pollutants, making them ideal for environments that require high levels of air purification, such as medical facilities, clean rooms, and industrial environments. They are used to accurately cut and divide filter paper into the required size and shape, ensuring uniformity of filter paper throughout the production process. They improve the efficiency of production lines by automating the segmentation process, reducing labor requirements, and minimizing human error. By installing a HEPA filter paper segmentation machine in a production line, manufacturers can increase production speed, achieve greater consistency in filter size, and ensure that the final product meets the high standards required for air filtration.

Fully automatic glue injection line in air filter production line equipment

Fully automatic glue injection lines are essential for air filter manufacturers who must assemble filters efficiently and accurately. The machine injects glue into the filter media and frame, ensuring a strong bond that holds the filter assembly in place. The automated nature of the system allows for high-speed production while maintaining the quality and consistency of glue application. Manufacturers can eliminate glue injection inconsistencies in manual processes by using a fully automatic glue injection line. This ensures that each filter uses the right amount of adhesive and is properly aligned, reducing the risk of defects and ensuring the overall effectiveness of the filter. At the same time, they also improve production efficiency because it can run continuously without frequent adjustments.

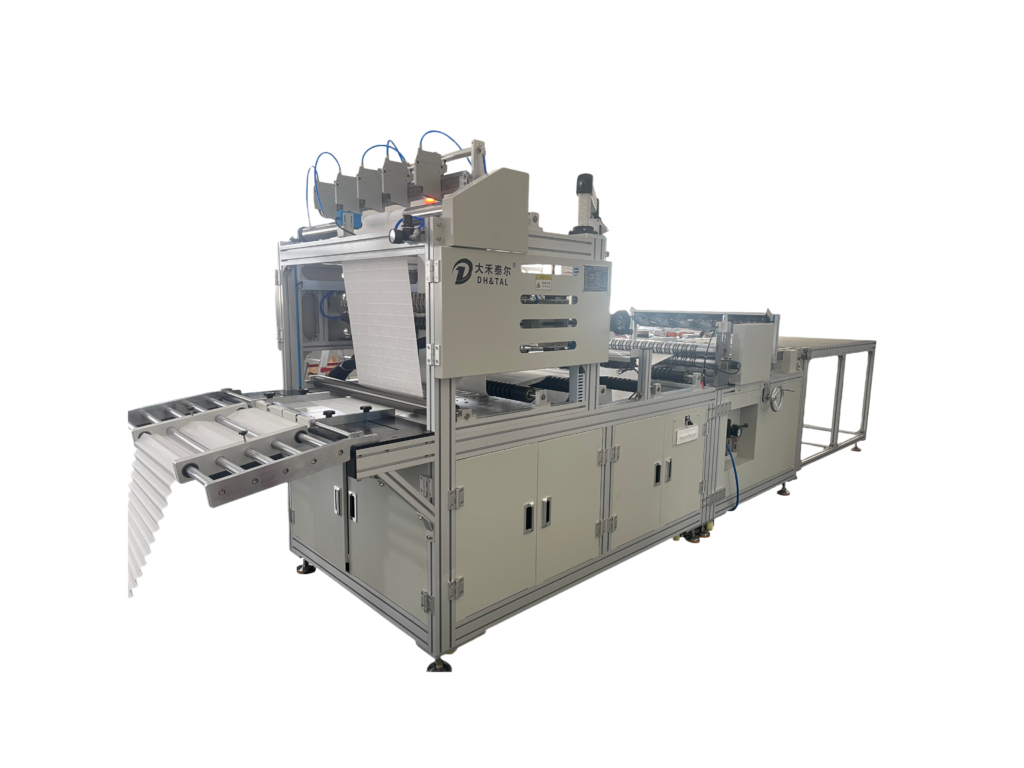

Paper pleating machine: Improving the precision of air filter construction

Paper pleating machines play a key role in air filter manufacturing, forming pleats in the filter media. These pleats increase the surface area of the filter, improving its ability to capture particles and pollutants from the air. The pleats also increase airflow while maintaining high filtration efficiency. The paper pleating machine is designed to automatically fold filter paper into precise, evenly spaced pleats, which are then used to assemble air filters. This process is critical to ensuring the filter material is efficient and durable. Automating this process reduces the need for labor and improves production’s overall speed and consistency. Dahe’s intelligent paper pleating machine has advanced features such as adjustable pleat depth and spacing to accommodate various filter sizes and specifications. This flexibility enables air filter manufacturers to produce a variety of filter types.

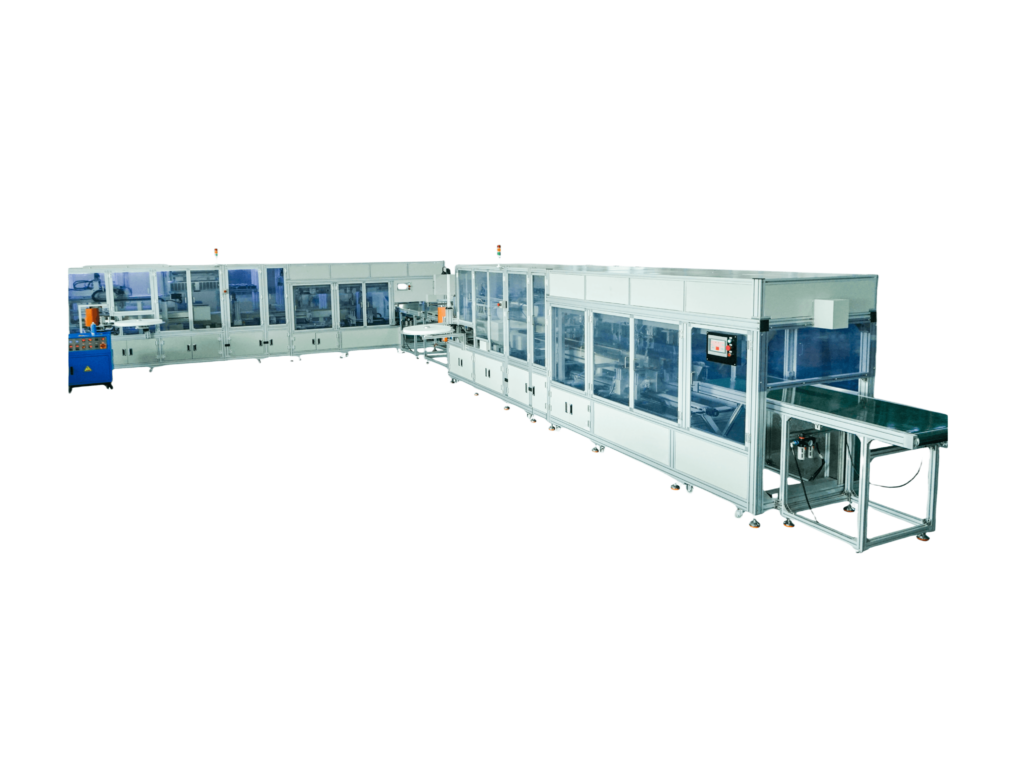

Fully automatic filter screen four welt production line: improve efficiency and quality.

The fully automatic filter screen four welt production line automates multiple stages of the air filter production process. The machine can perform tasks such as sealing the edges of the filter media, installing the frame, and inserting the filter element into the protective shell. The four-sided production line can significantly reduce production time and labor costs by automating these steps. It ensures that all produced filter elements are of consistent quality. The automation of the machine ensures that each filter element is properly and evenly sealed, eliminating human errors and ensuring that the final product meets strict quality standards. At the same time, precision also minimizes material waste, making it an environmentally friendly choice. The fully automated filter four-sided production line integrates various functions into a single system, streamlining the production process and enabling manufacturers to achieve higher output and reduce operating costs.

Customizing the production line to meet specific needs

Each air filter manufacturer has unique requirements based on the type of filters it produces, the industries it serves, and the volume of business. Customizing air filter production lines is essential to meet these needs and ensure optimal performance. Dahe Intelligent’s customization services include adjusting the size and capacity of the equipment, adding additional features such as specialized coating systems, or modifying the machine configuration to accommodate specific filter materials. For example, you can customize the HEPA filter paper splitter to the manufacturer’s specifications to handle different types of filter media, such as activated carbon or fiberglass. This flexible customization allows you to create a production line that meets their requirements.

Build an efficient, scalable air filter production line.

In summary, manufacturers’ best air filter production line equipment solutions include a range of high-quality, automated machines such as HEPA filter paper slitting machines, glue injection lines, paper pleating machines, and fully automatic filter screen four welt production lines. These devices work together to streamline the production process, reduce costs, and improve the overall quality of the final product.