Automotive air filters are essential components in automotive engines that prevent dust, debris, and other harmful particles from entering the system. As the automotive industry rapidly develops, the technology for manufacturing these critical components is also evolving. Therefore, more advanced and comprehensive automation is needed on automotive air filter manufacturing equipment to improve production efficiency and product quality. In the past, manufacturing automotive air filters often required a lot of labor and manual adjustments, resulting in low efficiency and high error rates. However, advances in automation and technology have greatly improved these processes. Today, automotive air filter manufacturing equipment is designed to operate with minimal human intervention, providing fully automatic control systems, high-speed production capabilities, and advanced servo drive systems.

Fully automatic control of automotive air filter manufacturing equipment

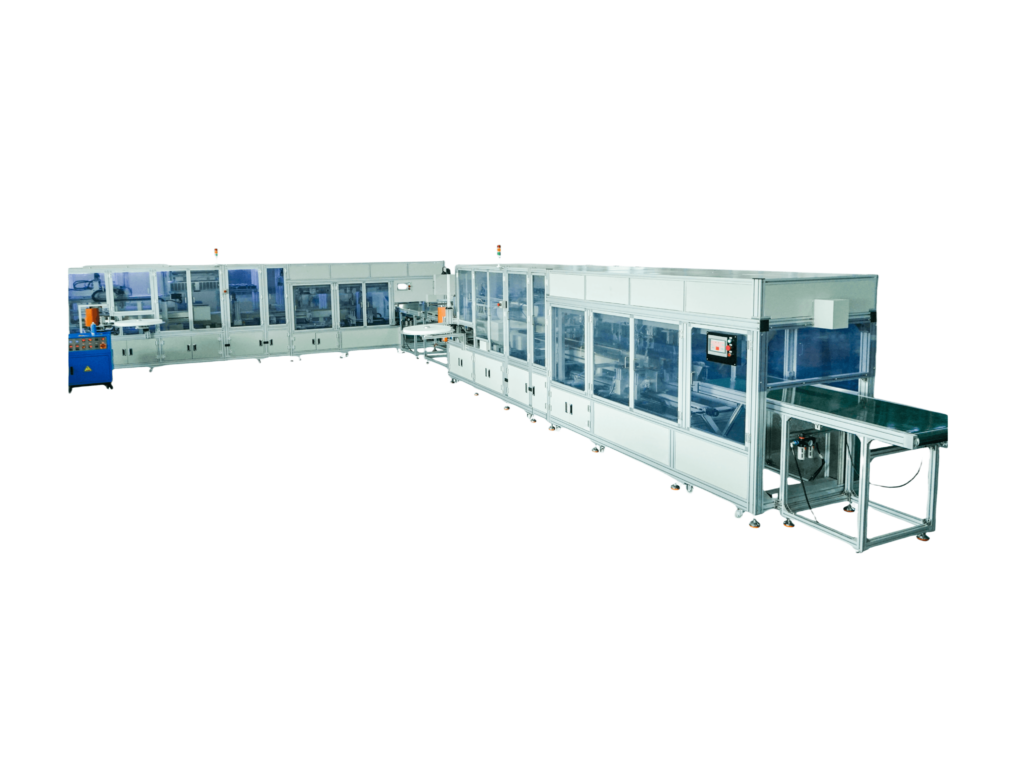

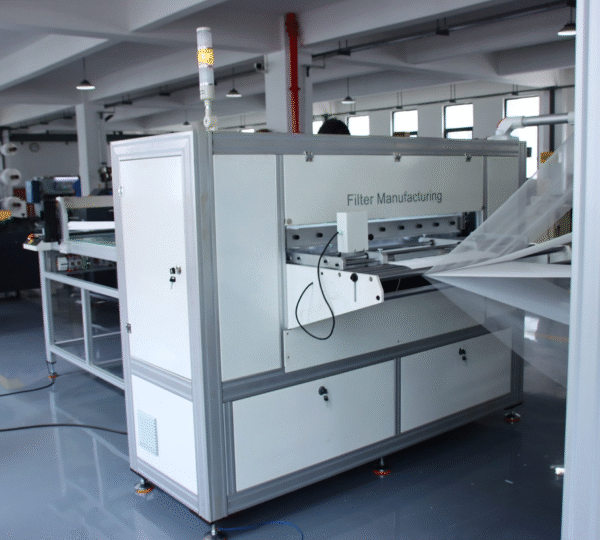

Unlike traditional manufacturing processes that require manual operation and adjustments, fully automatic control systems can control every aspect of the production line. This includes managing material flow, adjusting machine settings, and monitoring production quality. The integration of automatic control systems ensures a streamlined production process, reduces human errors, and improves overall efficiency. For example, the four-sided welt production line in the automotive air filter manufacturing equipment can see that this automatic control system is intuitively designed, providing operators with an easy-to-use interface and real-time data on the status of the production line. This allows operators to automatically adjust settings such as cutting parameters, product size and speed according to predefined parameters.

Fully analog servo drive in automotive air filter manufacturing equipment

Another important feature of automotive air filter manufacturing equipments is the fully analog servo drive system. This system mainly supports the four-sided welt production line in automotive air filter manufacturing equipment, where it accurately controls all parts of the production process. In automotive air filter manufacturing, servo drives control the speed, torque, and position of key equipment such as cutting tools, conveyors, and robotic arms.

The use of analog servo drives can achieve smoother and more accurate adjustments in the automotive air filter manufacturing process. These systems can quickly respond to changes in production requirements, ensuring that each part of the process runs synchronously with minimal delays or interruptions. For example, during the cutting and forming process, analog servo drives adjust the movement of the cutting tool with high precision, and they ensure that the cutting tool cuts each filter to the exact specifications required.

Fully automatic adjustment of product size

In traditional manufacturing methods, size adjustment is usually a manual process that requires operators to personally change machine settings or tools. This can be time-consuming and prone to human error. However, fully automated adjustment systems are available on automotive air filter manufacturing equipment, which can quickly and accurately change product sizes without human intervention. This automatic shaping function is particularly important in automotive air filter production, as different car models require different filter sizes. Instead of stopping the production line to manually adjust the equipment, the fully automated system can adjust product sizes in real-time based on pre-programmed parameters. This ensures that the system produces the correct filter size for each specific application, improving the efficiency of the production process and the accuracy of the finished product.

Automatic product movement with robotic arms

Robotic arms can automatically move products throughout the production line. Robotic arms handle a variety of tasks, from placing raw materials into the machine to transferring the finished filters for packaging or storage. Integrating robotic arms into the manufacturing process adds a level of flexibility and precision that is difficult to achieve manually alone.

One of the main advantages of robotic arms is their ability to move products efficiently and consistently. In automotive air filter manufacturing, robotic arms transport filters between different stages of production, ensuring that they handle each filter carefully and accurately. This reduces the risk of damage during handling and minimizes the need for human intervention. In addition, automating product movement using robotic arms improves overall workplace safety and reduces the risk of accidents or injuries.

Better and more efficient automotive air conditioning filter production

Advanced technologies such as fully automatic control, analog servo drives, automatic adjustment, and robotic arms integrate into automotive air filter manufacturing equipments. These features have revolutionized the production process, allowing manufacturers to improve the efficiency, precision and quality of their products. These features not only increase production speed but also ensure the consistency and reliability of each filter produced.