The three-axis dispensing machine stands out for its precision and versatility, making it an indispensable part of modern manufacturing. Generated report data from our customer sites shows that throughput increased by 40% after switching from manual to automatic dispensing systems. The Dahe intelligent three-axis dispensing machine includes synchronous belt drive motion and graphic programming functions for points, lines, dashed lines, 3D arcs, circles, runways, and rectangles. It also provides rich manual teaching and real-time graphic preview functions, while allowing for conditional jump functions and dual MARK rotary needle functions to achieve complex dispensing logic and other advanced features.

Designed for air filter frame dispensing

This three-axis dispensing machine is designed for air filtration manufacturers and excels in dispensing round and square filter frames. In addition to conventional dispensing, the machine’s path planning can adapt to the precise geometry of the pleated filter element frame. Additionally, customised formulations can be developed for various adhesives and substrates to ensure optimal wetting and bonding strength. Additionally, the high-precision dispensing of the three-axis dispensing machine minimises glue waste and rework, ensuring stable sealing performance that meets stringent air quality standards. It also simplifies switching between different filter frame sizes, as stored dispensing programs can be loaded instantly, significantly reducing downtime during line changeovers.

Timing Belt Drive and Motion Accuracy of the Three-axis Dispensing Machine

A significant feature of the three-axis dispensing machine is its timing belt drive, which enables high-speed and precise positioning in the X, Y, and Z axes. For example, the machine can draw fine graphic elements such as 0.1 mm lines or 3D arcs, enabling consistent bead width on complex filter frames. At the same time, I calibrated the tension and encoder feedback loop of each belt to ensure repeatability within a tolerance of ±0.02 mm. Additionally, the rigid frame and anti-backlash mechanism ensure accuracy even under high-load dispensing cycles. These motion control features make our three-axis dispensers ideal for high-volume, high-precision adhesive applications. Low-friction belt materials and automatic tension adjustment systems also reduce user maintenance requirements, further increasing uptime and reducing operating costs.

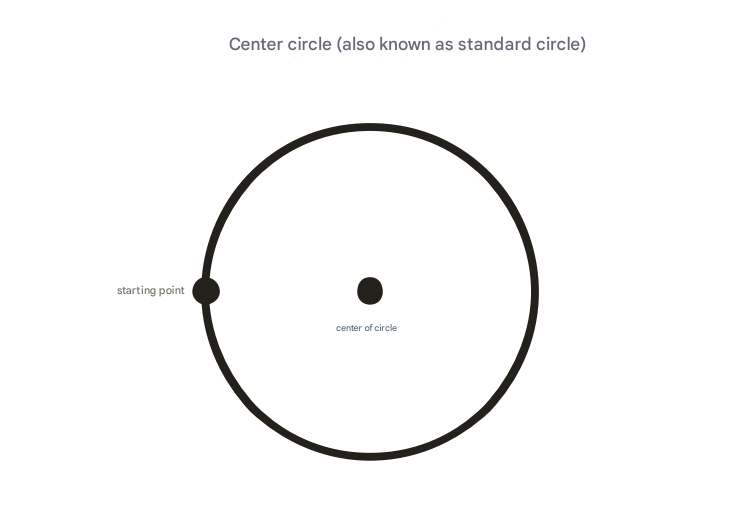

Graphical Programming and Preview

Graphical programming transforms the three-axis dispenser into an intuitive tool for the operator. Users can directly import CAD drawings. The machine then automatically generates the dispensing path. Technicians can also use the onboard graphical preview function, which simulates the dispensing path before execution, preventing errors. Furthermore, the manual teach function enables operators to adjust dispensing points in real-time, ensuring rapid prototyping and process optimization. By combining graphical programming with real-time preview, our dispensers minimize setup time and maximize batch yield. This streamlined workflow enhances consistency across shifts and facilitates the rapid replication of recipes for various substrate types or geometries.

Conditional Jump and Dual MARK Rotary Needle for Three-axis Dispensing Machine

Advanced logic control distinguishes the three-axis dispensing machine from basic dispensers. The conditional jump command allows the machine to change the dispensing sequence based on sensor input. Additionally, the dual MARK rotary needle function allows for continuous rotation, preventing adhesive clogging and ensuring smooth bead formation. I configure these functions to adjust the dispensing speed or path when encountering corners or material changes. This adaptive control ensures reliable dispensing on irregular frames, making these automatic dispensers highly adaptable to complex production needs. Additionally, integration with vision systems enables closed-loop verification, triggering jumps only when quality thresholds are met, thereby enhancing the robustness of the overall process.

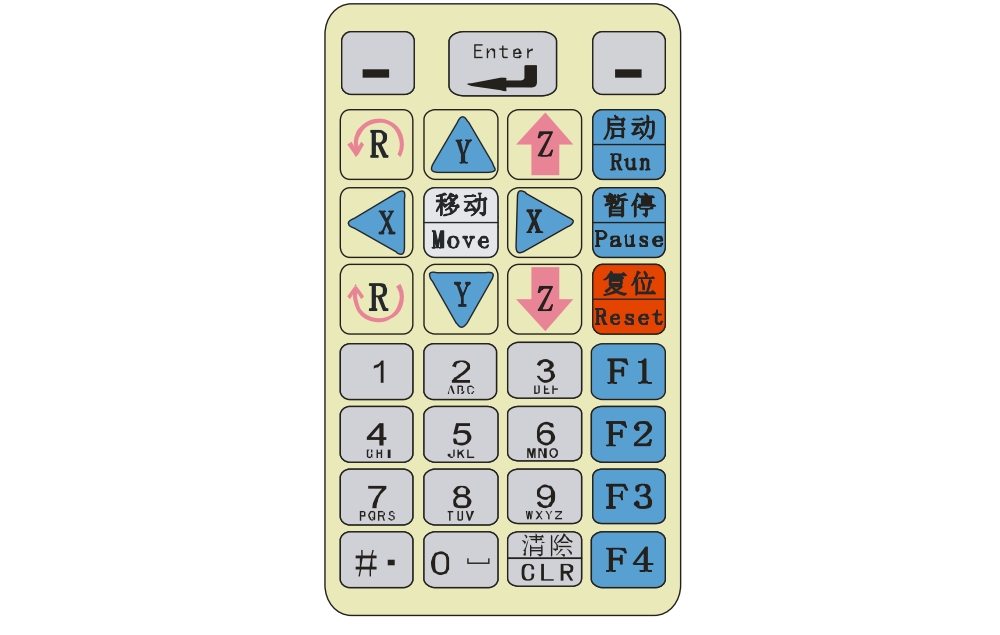

Motion Control Card and Handheld Operation

The three-axis dispensing machine uses an industrial-grade motion control card for precise synchronization and provides a handheld operation console for easy on-site adjustments. For example, the control card processes trajectory calculations at a high frequency, thereby achieving a motion trajectory with limited jitter. I recommend that field technicians use the handheld operation box for fast position coverage, manual extrusion control, and process monitoring. At the same time, USB and Ethernet connections can be seamlessly integrated with factory networks and data logging systems. This combination of centralized control and portable operation enables production teams to maintain uptime and quality. Additionally, the console’s ergonomic design reduces operator fatigue and supports a multi-language interface, enabling international deployment.

Bring more convenient dispensing production.

The functional features of the three-axis dispensing machine include a synchronous belt drive, precise control of complex graphic elements, intuitive graphics programming with preview, conditional jump logic, a double MARK rotating needle anti-blocking feature, motion control card synchronisation, handheld operation, and other functions. You can fully utilise these features to achieve higher throughput, reduce waste, and improve bonding quality.