Compared with manual processes, automatic edge strip scraping machines can reduce labor time by more than 60%, reduce scrap rates by nearly 45%, and increase overall production by 30%. The automatic edge strip scraping machines we offer have automatic feeding functions, as well as synchronous feeding and winding functions to maintain a continuous production process. These machines can save and recall multiple model parameters, automatically set the scraping length and depth, and autonomously perform scraping and cutting without requiring operator intervention. In addition, Dahe’s intelligent automatic edge scraping machines also feature both manual and automatic modes, providing operators with the flexibility to prototype unique filter designs or run mass production seamlessly.

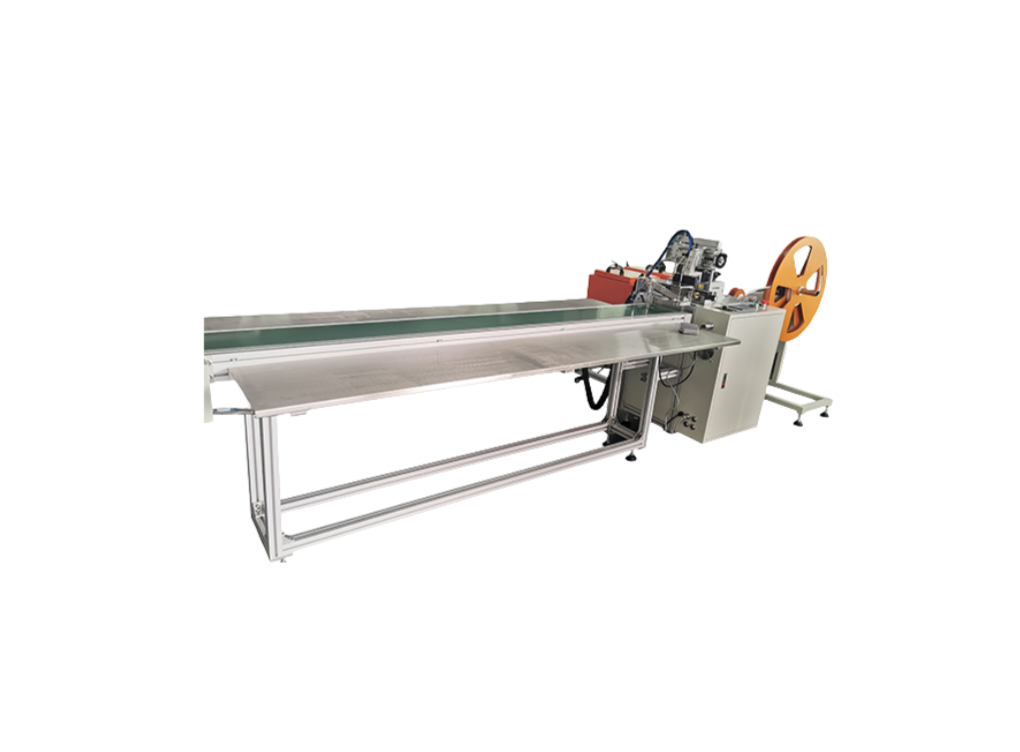

Automatic edge strip scraping machines enhance production efficiency through automated feeding.

One of the main advantages of the automatic edge strip scraping machine is its fully automatic feeding mechanism, which can significantly increase production line speed. When a material roll is required, it can be unrolled, accurately aligned, and fed into the scraping station without manual intervention. Additionally, the integrated winding device can simultaneously wind the processed edge strips, thereby maintaining continuous operation and minimizing material downtime. Meanwhile, I configured the servo-driven feeder to handle a wide range of material widths at speeds of up to 30 meters per minute, effectively doubling throughput compared to manual loading methods. This automation reduces downtime associated with manual operations. By integrating automatic feeding and winding functions, these machines enable skilled technicians to focus on quality control, secondary processing tasks, and process optimization.

Accuracy and Repeatability through Parameter Recall

Another significant benefit of the automatic edge strip scraping machine is its ability to save and recall multiple model parameters for different filter element designs. In addition to storing strip lengths, scraping depths, and cut positions for different filter element configurations, the system ensures that each new production run meets previously validated specifications with zero tolerance drift. The HMI in the automatic strip skiving machine stores up to 50 unique profiles, enabling fast changeover in under two minutes and eliminating manual setup errors. This parameter recall feature eliminates operator guesswork, reduces setup time, and maintains repeatable accuracy, even after extended downtime. As a result, manufacturers can achieve consistent strip tolerances within ±0.1 mm between production batches, further improving final filter element performance and reducing downstream assembly issues caused by dimensional variations.

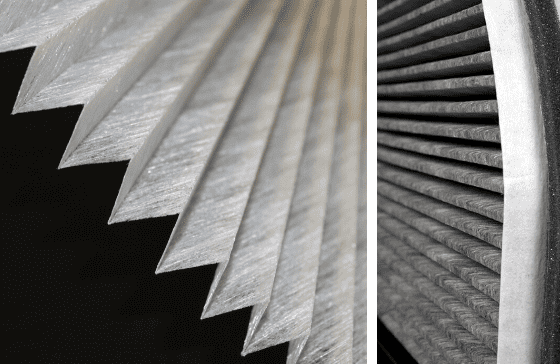

Automatic edge strip scraping machines with Adaptive Scraping Depth Control

Automatic edge strip scraping machines also feature adaptive scraping and depth control mechanisms to protect delicate filter media and ensure uniform strip removal. For example, real-time load cells and laser displacement sensors continuously monitor material thickness, dynamically adjusting scraper position to maintain precise scraping depth. Additionally, we have integrated a closed-loop feedback system that enables the scraper to be adjusted with a resolution of 5 microns while the automatic strip scraper is in operation, compensating for changes in filter media density and fiber orientation. This adaptive control prevents both over-scraping and under-scraping (leaving behind excess material that can interfere with the filter function). By ensuring precise and consistent strip removal with every cycle, these devices minimize waste, improve filtration efficiency, and contribute to overall product quality.

Seamless cutting and component separation

Traditionally, cutting and separating edge strips is a labor-intensive process, but the automatic edge strip scraper automates this step with an integrated precision cutting station. The pneumatic or servo-driven rotary cutter engages at programmed intervals; however, the machine intelligently adjusts the blade speed and dwell time to adapt to the material hardness and prevent wear. Additionally, we have incorporated a high-speed rotary cutter, which enables clean cuts without burrs or fibers at production speeds of up to 20 times per minute. An AA synchronous vacuum pickup device can accurately fix and deliver the trimmed edge strips to a designated collection box, eliminating manual operations and reducing the risk of contamination. This automated scraping and cutting sequence reduces dust generation, improves operator safety, and obtains uniform edge strip lengths that can be assembled or packaged immediately, significantly speeding up downstream processes.

Flexible operation in manual and automatic modes

Dahe’s intelligent automatic edge strip scraping machine uniquely supports manual and automatic modes, providing manufacturers with critical operating flexibility. In addition to the fully automatic mode for high-volume production, the manual mode allows skilled operators to move the scraper in a custom pattern or make dynamic fine adjustments. Therefore, the same platform can seamlessly switch between new design prototyping and large-scale production. Additionally, I integrated a two-hand safety control in manual mode, which requires simultaneous button presses to gradually move the scraper, thereby ensuring the operator’s safety during setup and trial operation. This dual-mode operation maximizes equipment utilization, reduces capital expenditures for individual machines, and supports just-in-time production strategies without sacrificing precision or quality.

Leverage automation for more flexible production

Automatic edge strip scraping machines have obvious advantages over manual scraping machines. Automatic feeding and winding can increase production by up to 60%. Parameter call ensures repeatability, the adaptive scraping function protects filter material integrity, the integrated cutting function simplifies part separation, and dual-mode operation provides unparalleled flexibility. With this automated filter production equipment, labor costs can be reduced by up to 50%, scrap rate can be reduced by 40%, and stable edge strip quality within ±0.1 mm can be achieved.