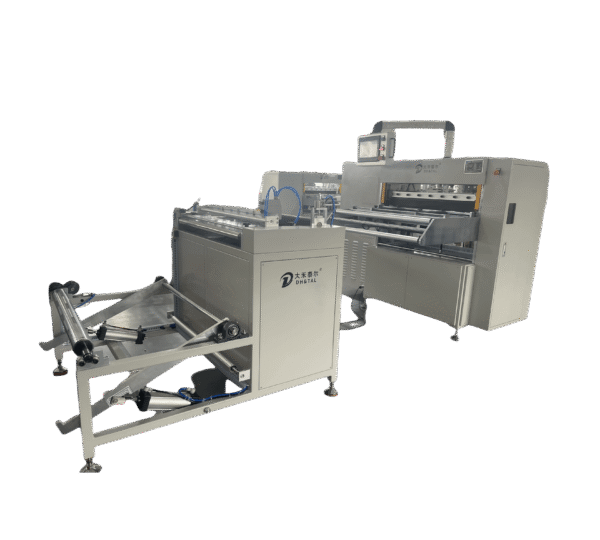

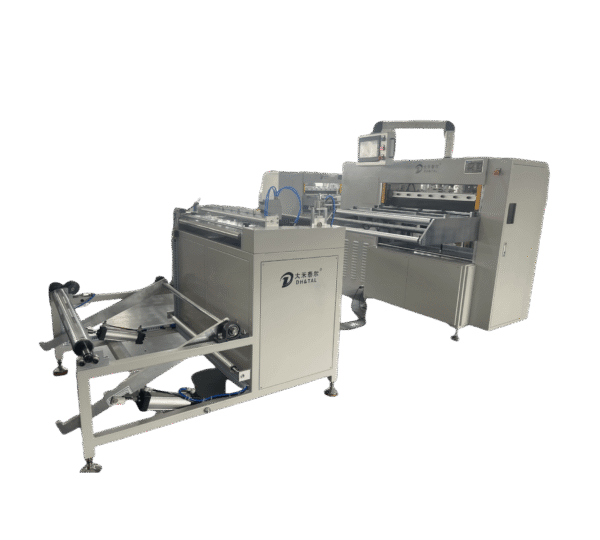

The function of an air filter pleating machine is to shape, compress, and fix the filter material into pleats for insertion into a frame or subsequent assembly. For small-batch production, manual or semi-automatic air filter pleating machines can achieve acceptable production cycles with lower capital investment. However, in medium- to high-batch production, fully automatic air filter pleating machines generally excel in repeatability and labor efficiency. It’s worth noting that Dahe Intelligent’s fully automatic worktable uses a stepper-motor-driven linear guide, enabling precise adjustment of pleating heights. Therefore, manufacturers can quickly switch product pleating depths without time-consuming mechanical mold changes or custom molds.

Air Filter Pleating Machine: Semi-Automatic vs. Fully Automatic Performance Comparison

In the filter manufacturing industry, production efficiency is key to profitability. When comparing semi-automatic and fully automatic air filter pleating machines, cycle time and consistency are the main differentiating factors. Semi-automatic paper pleating machines typically require an operator to feed the material, start the pleating cycle, and sometimes manually align or clamp the pleats before fixing. Therefore, the operator’s skill and fatigue level directly affect cycle time and scrap rate. Conversely, fully automatic air filter pleating machines automate feeding, pleating, and unloading, ensuring consistent cycle times across shifts.

Specifically, Dahe Intelligent employs a fully automatic worktable architecture with stepper-motor-driven linear guides, enabling rapid, repeatable adjustments to varying fold heights. This electromechanical precision reduces the need for manual adjustments, thus preventing production interruptions. Furthermore, compared to pneumatic or cam-based systems common in semi-automatic models, servo motors and rack-and-pinion driven pleating and lifting motions provide smoother acceleration and deceleration curves. The result is reduced mechanical shock, lower pleating error rates, and shorter maintenance downtime—all of which contribute to improved overall production efficiency.

Quality and Consistency: How Automation Improves Fold Geometry

The quality of filter manufacturing depends on fold geometry—uniform depth, consistent spacing, and reliable seam formation. Paper pleating machines must produce repeatable fold geometries to ensure filtration performance, minimize pressure drop variations, and meet customer specifications. Semi-automatic air filter pleating machines can produce acceptable results for simple filter geometries. Still, they inherently exhibit greater variability because they rely more on operator skill in feeding, alignment, and clamping.

In contrast, fully automatic air filter pleating machines offer greater consistency. A linear guide on the worktable, driven by a stepper motor, combined with a servo motor and a rack-and-pinion-driven pleating/lifting mechanism, enables deterministic motion control. In short, this paper pleating machine repeats the same movements and positions in each cycle, thus stabilizing the height and spacing of the folds. If you require precise fold spacing for folded HEPA, ULPA, or high-efficiency automotive cabin air filters, the predictability of a fully automatic air filter pleating machine will significantly reduce the rate of defective products.

Labor, Ergonomics, and Operating Costs

Operating costs are not just the price of the machine; they also include labor, training, ergonomic risks, and ongoing maintenance. Semi-automatic paper pleating machines typically require a higher operator-to-machine ratio. Operators need to feed, monitor the cycle, and make adjustments; therefore, shift hours increase as production targets are met.

In contrast, fully automatic air filter pleating machines reduce reliance on operators by automating processes. Stepper motor-driven linear guides enable rapid formula changes and minimize manual setup. Servo motors and rack-and-pinion-driven pleating and lifting mechanisms enable repeatable movements with minimal human intervention. Furthermore, automatic stop alarms prevent repetitive worker errors and reduce time wasted due to material shortages. Therefore, employees can be redeployed to value-added activities such as quality control, packaging optimization, or continuous improvement. From an ergonomic perspective, semi-automatic systems often require repetitive manual operations, increasing the risk of injury and absenteeism in the long run. Fully automatic paper pleating machines reduce repetitive strain injuries by automating paper feeding and output, thereby improving workplace safety and employee satisfaction.

Flexibility, Turnaround Time, and Product Diversity of Air Filter Pleating Machines

Modern filter manufacturing demands high flexibility. Paper pleating machines must be able to adapt to different filter media types, fold depths, and fold counts to meet seasonal or customer-specific product mix needs. Semi-automatic air filter pleating machines have a significant advantage in low-volume, high-variety production environments because they typically use simpler molds and are easier to adjust. For small-batch production or prototyping, the manual adjustment functions commonly used in semi-automatic machines allow for rapid experimentation without complex programming.

However, when product variety and scale coexist, fully automatic air filter pleating machines offer superior flexibility for large-scale production. Stepper motor-driven linear guides enable rapid, repeatable adjustments in pleating height. Furthermore, servo motors and rack-and-pinion-driven pleating and lifting mechanisms allow for programmable parameters to be set for different media hardness and fold density, which is crucial when switching between lightweight synthetic media and denser paper pleating substrates. When selecting between semi-automatic and fully automatic paper pleating machines, it is essential to consider not only existing product variety but also projected product turnover rates. If the product mix is stable and production cycles are long, fully automatic systems offer higher efficiency and repeatability.

Reliability, Maintenance, and Safety Considerations

Reliability is critical for continuous production. Semi-automatic paper pleating machines typically employ simple mechanical connections and pneumatic actuators, which, while easy to troubleshoot, can experience performance fluctuations and wear under high cyclic loads. Fully automatic air filter pleating machines use precision drive units (stepper or servo motors), linear guides, and rack-and-pinion mechanisms to deliver repeatable performance.

At Dahe Intelligent, we prioritize ease of maintenance when designing fully automatic workbenches. The stepper motor-driven linear guides enable predictable wear patterns and simple replacement cycles. The servo motor and rack-driven pleating and lifting mechanisms offer high stability and integrate position encoder feedback for real-time diagnostics. These diagnostic functions, combined with automatic shutdown alarms for low material levels, reduce the probability of catastrophic failures and support condition-based maintenance. Semi-automatic systems, on the other hand, place higher demands on operators, potentially exposing more people to risks of pinching, manual handling, and repetitive actions. Fully automatic paper pleating machines are typically equipped with protective covers, interlocking devices, and programmable safety states to isolate operators from moving parts.

How to Choose the Right Machine?

Choosing between semi-automatic and fully automatic air filter pleating machines requires an objective analysis based on your production goals. For production processes requiring high-volume manufacturing, stringent quality standards, or reduced reliance on manual labor, fully automatic paper pleating machines are typically ideal. Stepper motor-driven linear guides enable precise, repeatable pleating height adjustment; servo motors and rack-and-pinion-driven pleating/lifting mechanisms ensure stable mechanical movement; and automatic stop alarms prevent cyclical waste due to insufficient material. These features work together to increase effective output, reduce waste, and enhance safety. If your business produces small batches, frequently conducts prototyping, or faces budget constraints, a semi-automatic air filter pleating machine may be a more suitable short-term option.