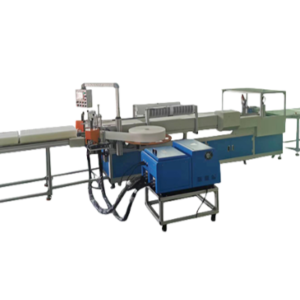

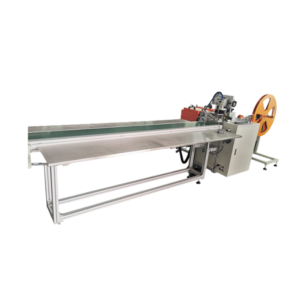

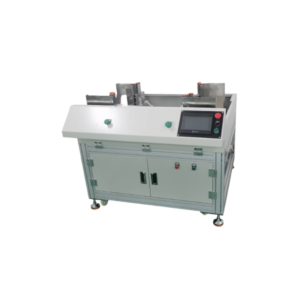

HEPA assembly machine

Product Introduction:

The HEPA Assembly Machine efficiently dispenses, presses, and assembles square HEPA filters. It features a three-axis dispensing system, dual pressure-holding units, and supports single-person operation for high efficiency and easy use.

Equipment parameters:

| Parameters of the HEPA assembly machine: | |

| Equipment size: | L3.1M*W1.0M*H1.85M.2. XYZ axis travel:600mm*500mm*150mm. |

| XYZ axis travel: | 600mm*500mm*150mm. |

| Maximum product size: | 500mm*600mm*70mm. |

| Minimum product size: | 100mm*150mm*10mm. |

| Maximum walking speed: | 800mm/s. |

| Power: | 10KW (including glue machine 8KW) |

| Working voltage 220V 50Hz Contains a 10KG glue machine, a streamline gun, a 3-meter hose, and 3 gun nozzles (L=65mm) Free 3 models of fixtures (2 wooden frame fixtures for each model) Production efficiency≥ 1200Pcs10h (depending on the efficiency of workers placing products and hemming) |

|

Equipment use:

HEPA assembly machine is used for dispensing, pressure holding, and assembly of square HEPA filters. Suitable for batch production.

Equipment advantages:

- The HEPA assembly machine uses a three-axis dispensing machine with a set of pressure-maintaining and automatic unloading devices on the left and right.

- The dispensed products are moved left and right to maintain pressure and complete the HEPA dispensing and pressing assembly work.

- One device is operated by one person, with high cost-effectiveness, simple operation and strong practicality.

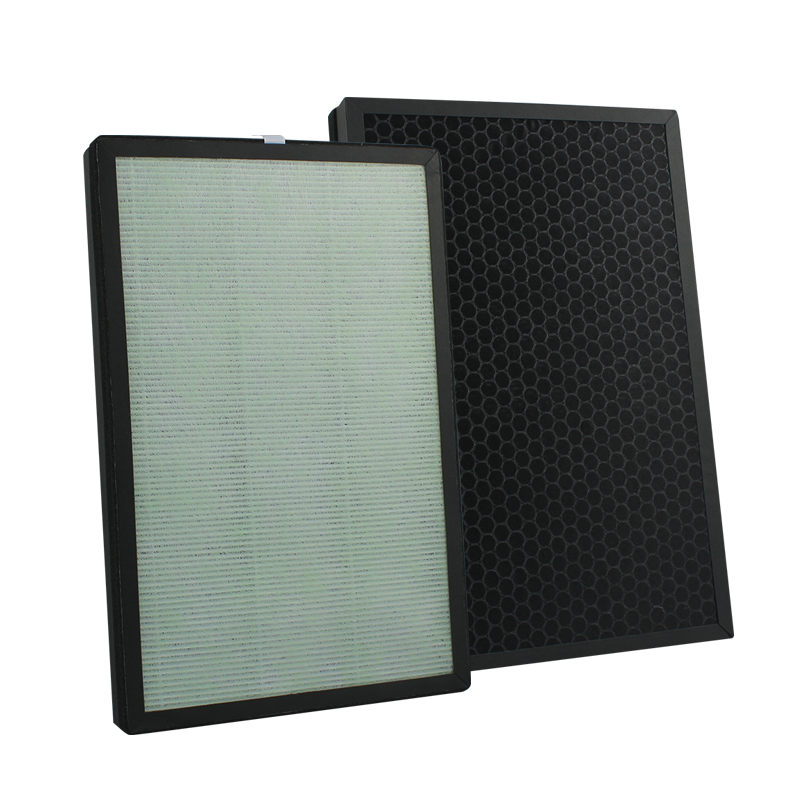

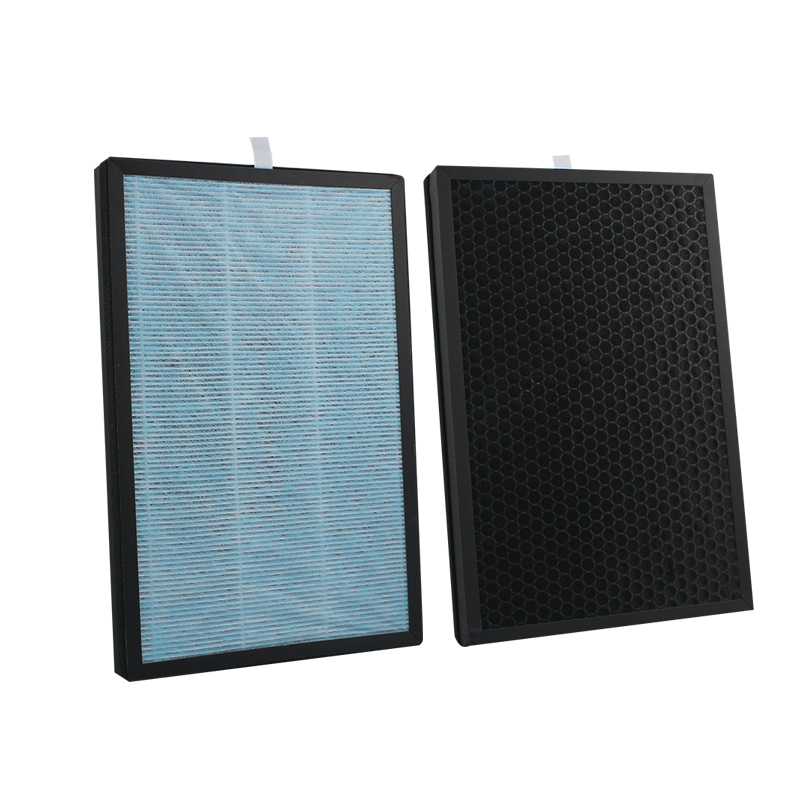

Suitable filters for production:

Professional filter equipment manufacturer

Please leave your contact information and our professional business consultants will provide you with corresponding solutions and quotations and answer your questions.

Customer Reviews

“This pleating machine has revolutionized our production process. We can now meet high demand and produce 40% faster without sacrificing quality or efficiency.”

James Murray

“The Paper pleating machine has increased the precision and efficiency of our production process. Our filter performance has improved significantly, which is critical to our customers.”

David Green

Join Our Newsletter

Related Products

Related products

-

Household air purification filter

Continuous welting machine on both sides

Rated 0 out of 5Read more -

Household air purification filter

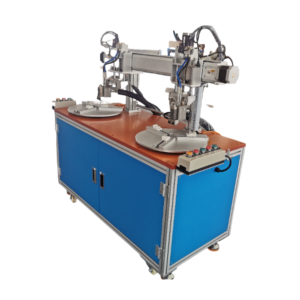

Circular dispensing machine-double station

Rated 0 out of 5Read more -

Household air purification filter

Automatic edge strip scraping machine-Single station

Rated 0 out of 5Read more -

Automobile air conditioning filter

Automatic edge trimming machine-4 corners

Rated 0 out of 5Read more

Contact

- Building 3, Simin Industrial Zone, No. 56 Xiaoxiang Wenming Road, Wanjiang District, Dongguan City

- +86 13560883391

- tableliu@126.com

- WhatsApp:+8613560883391

SHORTCUT LINKS

- Home

- Product

- About Us

- Video Case

- Contact Us

- Blog

PRODUCTS

- Automobile air conditioning filter production

- Household air purification filter

- Vacuum cleaner and sweeping robot filter

- Hot melt adhesive machine

- Precision machinery parts processing

Contact us

© Copyright 2024 Technical Support: Lezhan