Paper Pleating Machine Operational Efficiency in Modern Factories

Operational efficiency no longer depends solely on speed. In modern factories, consistency, stability, and material control define real productivity. A well-designed Paper Pleating Machine sits at the center of this shift, integrating precise feeding, controlled pleating, and intelligent safety mechanisms into one unified system. From filter paper processing to industrial pleating applications, manufacturers now expect machines to deliver repeatable results while minimizing downtime and material waste.

As a manufacturer dedicated to the design, development, and production of Paper Pleating Machines, we approach efficiency as a system-level outcome. Every structural component, motion unit, and control mechanism works together to ensure that pleated paper maintains uniform height, spacing, and tension throughout continuous operation. This holistic approach allows factories to scale output without compromising quality or operator safety.

Paper Pleating Machine Feeding and Slitting System for Stable Material Control

Material stability begins at the feeding stage. The Paper pleating system integrates a slitting feeding unit composed of a feeding mechanism and a traction mechanism, both engineered to maintain constant paper tension during operation. The feeding shaft uses a graduated pneumatic shaft paired with a magnetic powder brake, enabling smooth unwinding and accurate tension adjustment even at higher production speeds.

Meanwhile, the indexing mechanism relies on a 750W motor to drive precise feed intervals. The feed drive wheel incorporates a pneumatic lifting cylinder, allowing operators to load material efficiently and reduce setup time. In addition, the feeding unit supports conveying and buffer storage limit functions, which help ensure consistent pleating even when upstream material flow fluctuates. When material runs out, the machine stops automatically, preventing damage and unnecessary waste.

Paper Pleating System: Structural Design for Long-Term Reliability

Durability plays a decisive role in operational efficiency. This Paper pleating system features a full-steel construction, providing the frame with exceptional rigidity and vibration resistance during continuous production cycles. Compared with lightweight or mixed-material structures, an all-steel body maintains alignment accuracy over time, even in demanding industrial environments.

Because structural stability directly affects pleating precision, this design choice allows factories to maintain consistent output with fewer mechanical adjustments. As a result, operators spend less time on recalibration, while maintenance teams benefit from longer service intervals and reduced wear-related issues.

Servo-Driven Folding and Lifting for Precision Control

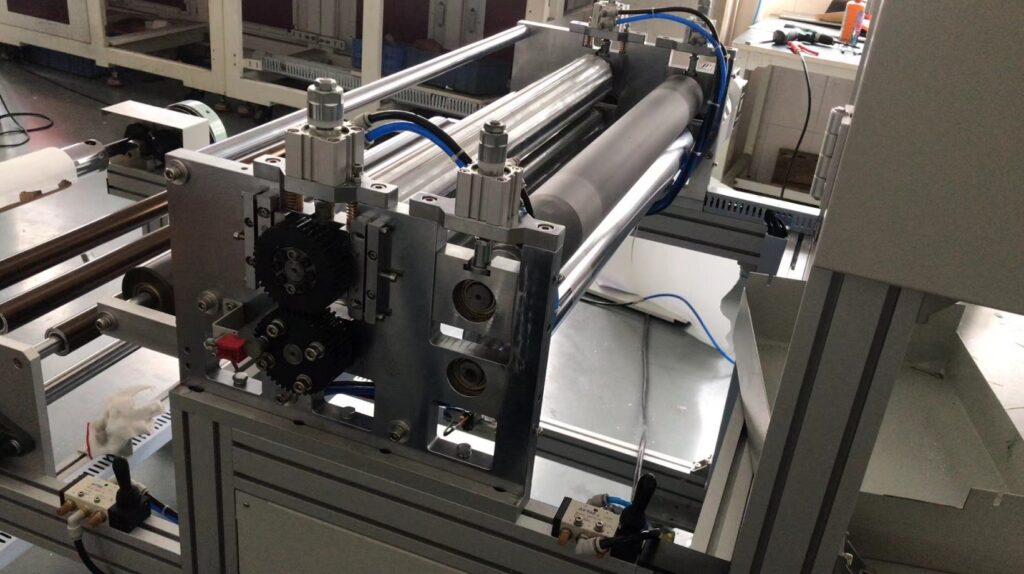

At the core of pleating accuracy lies motion control. The Paper pleating system uses servo motors to drive rack-and-pinion mechanisms for folding and lifting. This configuration delivers smooth, repeatable motion while maintaining precise control over pleat height and spacing.

Unlike conventional mechanical drives, servo-driven systems respond quickly to parameter changes and maintain accuracy across long production runs. This stability proves especially valuable when processing filter paper with strict dimensional requirements. As a result, manufacturers achieve higher yields and reduce rejections caused by uneven folds or inconsistent pleat geometry.

Table Forming Results Through Controlled Heating

Temperature management significantly influences pleating quality. To address this, the Paper pleating system features a preheating function on the front worktable, while the rear worktable integrates both heating and thermal insulation. Together, these zones create a controlled forming environment that stabilizes pleat shape during and after folding.

By maintaining consistent thermal conditions, the machine reduces material rebound and deformation. This design helps ensure that pleats remain uniform once formed, especially during high-speed operation. Consequently, factories can maintain steady output without frequent manual corrections.

Paper Pleating Machine, Adjustable Worktable, and Output Stability

Flexibility remains essential for modern production lines. The Paper pleating system worktable uses linear guides driven by a stepper motor, allowing operators to precisely adjust the folding height for different product specifications. This adaptability supports multiple filter designs without extensive mechanical modification.

At the output stage, the folding paper section includes a pressure strip that firmly holds the pleated filter paper. Operators can adjust the pressure strip height according to actual production needs, ensuring stable discharge and preventing deformation. These features together enhance overall process consistency while simplifying changeovers between product types.

Paper Pleating System: Safety, Monitoring, and Intelligent Protection

Operational efficiency also depends on safety and visibility. The Paper pleating system includes safety indicator lights that alert operators to the machine’s status, helping prevent damage from incorrect operation. Both the front and rear enclosures feature observation windows, allowing operators to monitor pleating conditions and adjust parameters in real time.

In addition, the machine supports automatic shutdown and alarm functions when the material supply becomes insufficient. This intelligent protection reduces material waste, prevents equipment damage, and supports safer daily operation. Over time, these safeguards contribute to lower operating costs and higher overall equipment effectiveness.