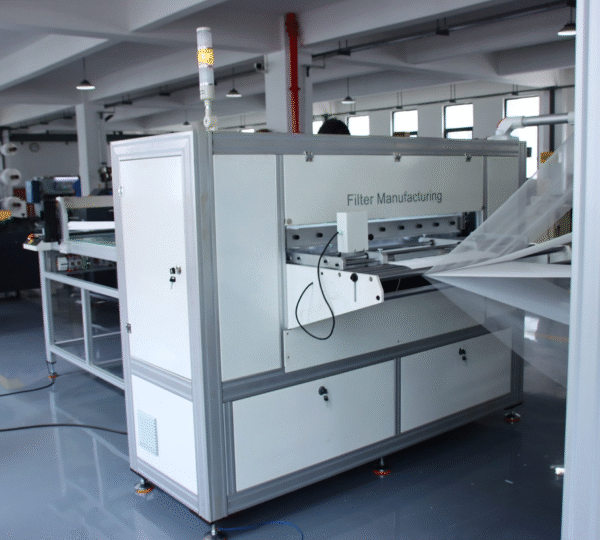

Consistency in air filtration determines how effectively a vacuum cleaner performs over time. Even the most powerful motor becomes useless if the filter fails to capture fine dust or loses efficiency too quickly. That’s where the Vacuum Cleaner Filter Production Equipment plays a defining role. Modern manufacturing lines now use automation, precision cutting, and real-time quality control systems to ensure every filter performs at the same high level. We’ll explore how advanced filter production technology ensures consistent filtration quality from the first filter to the millionth.

Precision Cutting is The Foundation of Filter Accuracy

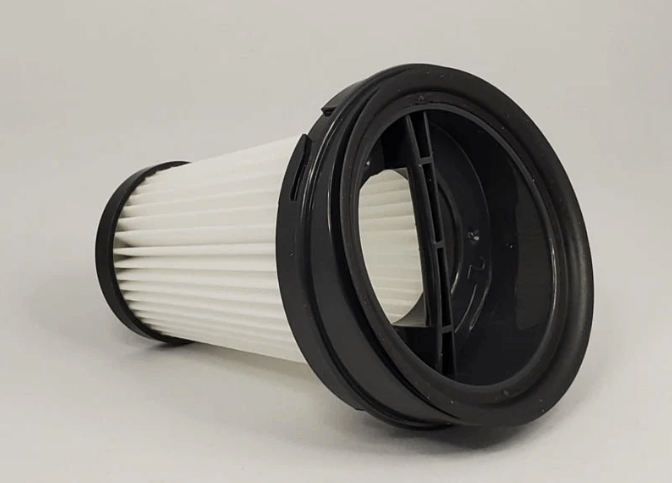

Every high-performance vacuum filter starts with precisely cut materials. The pleated filter media—often made of HEPA-grade microfiber or melt-blown fabric—must maintain uniform dimensions to ensure stable airflow and dust retention.

Automated slitting and die-cutting machines in Vacuum Cleaner Filter Production Equipment deliver tolerances within ±0.1 mm. According to a 2024 study by Filtration + Separation Journal, even a 0.3 mm deviation in pleat spacing can reduce dust holding capacity by 7%. That level of precision can only be achieved through servo-driven systems and laser-guided alignment, ensuring filters maintain identical geometries across large batches.

Automated Pleating and Sealing for Repeatability

Uniform pleating is another critical factor in maintaining filtration consistency. Manual pleating often leads to uneven fold depths or compressed fibres, affecting pressure drop and airflow.

Today’s Vacuum Cleaner Filter Production Equipment uses servo-controlled pleating machines capable of handling up to 600 pleats per minute while maintaining exact fold dimensions. These systems integrate with hot-melt or ultrasonic sealing units, ensuring each fold is perfectly bonded and free from leakage points. As a result, every filter provides identical resistance and structural stability, essential for long-term dust containment.

Material Feeding and Tension Control Systems

Material consistency begins at the feeding stage. Uneven web tension can distort filter geometry and compromise bonding quality.

Modern Vacuum Cleaner Filter Production Equipment employs closed-loop tension control and automatic edge alignment systems. Sensors monitor fabric stretch in real-time and adjust roller speed to prevent fibre deformation. Brands like Hengst and Freudenberg have adopted these systems to stabilise HEPA filter production, improving yield consistency by up to 12% while reducing waste. Such precision handling ensures that even lightweight nonwoven fabrics maintain dimensional stability throughout production.

Integrated Inspection and Quality Monitoring

Consistency doesn’t end after cutting or sealing—the inspection phase is where quality assurance is locked in. Vision inspection systems, now standard in advanced Vacuum Cleaner Filter Production Equipment, use high-speed cameras to detect pleat misalignment, uneven sealing, or contamination.

These systems can automatically reject defective filters before assembly, ensuring only compliant units proceed to packaging. Data from a 2023 Emerson automation report showed that integrating optical inspection reduced post-production defects by 18%, significantly improving batch reliability. Real-time feedback loops also allow operators to adjust machine parameters instantly, keeping every filter within spec.

Maintaining Cleanroom Conditions for Filter Integrity

Since many vacuum cleaner filters are rated as HEPA (High-Efficiency Particulate Air), they must be produced in controlled environments. Even microscopic contamination during production can reduce performance.

High-end Vacuum Cleaner Filter Production Equipment lines are often installed in ISO Class 8 or better cleanrooms, ensuring ambient particle levels remain low. Air showers, antistatic surfaces, and filtered air supply systems prevent dust infiltration during assembly. Maintaining such an environment helps manufacturers guarantee the same particle capture rate for every filter batch, an essential factor in customer satisfaction and regulatory compliance.

Case Study: HEPA Filter Production Line Efficiency

A 2024 case from Panasonic’s vacuum filter plant in Malaysia illustrates the power of automation. After upgrading its line with a fully automated Vacuum Cleaner Filter Production Equipment system featuring servo pleating, hot-melt sealing, and optical inspection, the plant increased output by 30% while cutting defect rates to below 0.5%.

This improvement translated into a 15% cost reduction per unit and a measurable increase in suction stability across all vacuum cleaner models using the new filters. It highlights how process consistency directly affects both filtration quality and production economics.

Common Challenges in Maintaining Filtration Consistency

Despite advanced technology, achieving perfect uniformity remains a challenge. Variations in raw materials, adhesive viscosity, or ambient humidity can affect bonding quality and pleat formation. Moreover, frequent line changeovers can introduce variability if machine calibration isn’t precisely maintained.

That’s why leading manufacturers implement predictive maintenance and data analytics within Vacuum Cleaner Filter Production Equipment. These tools monitor temperature, adhesive flow rate, and servo performance to preempt any deviation. By analysing machine data, operators can detect trends early and correct them before quality drifts occur.

Precision Equipment Defines Filtration Reliability

Consistency in vacuum cleaner performance ultimately begins on the production floor. Precision-driven Vacuum Cleaner Filter Production Equipment ensures that every filter captures dust effectively, resists deformation, and maintains airflow stability over time. With continued innovation in automation, material control, and inspection technology, manufacturers can now guarantee filtration reliability that meets the increasingly stringent demands of both consumers and global standards.