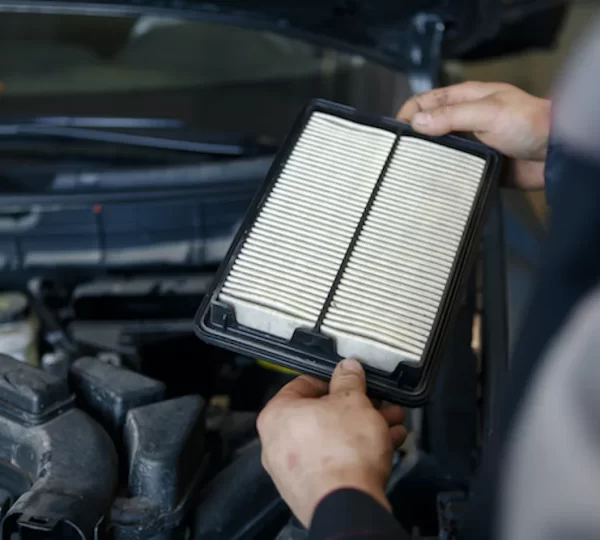

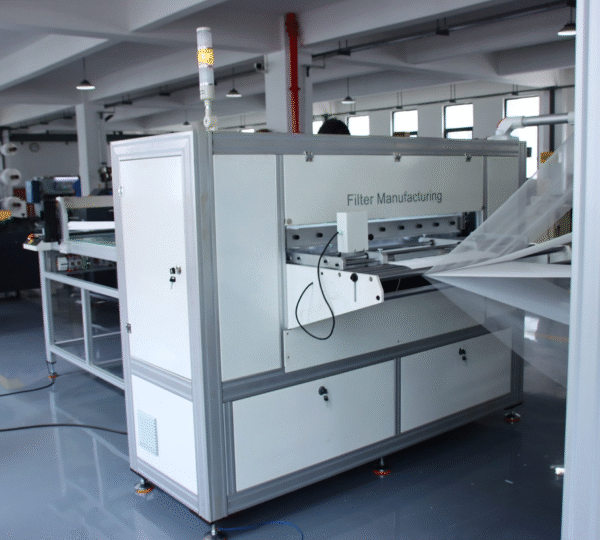

Pleating Machines for Filters often face operational challenges that reduce efficiency and quality. Identifying and fixing issues quickly prevents downtime and scrap. Begin by inspecting material feed, blade condition, and pleat alignment. Meanwhile, monitor machine speed and tension settings carefully. Regular maintenance and operator training minimise errors. Also, log recurring issues for continuous improvement. Following these steps ensures stable operation and high-quality output from Pleating Machines for Filters.

Material Feed Problems

Incorrect or inconsistent material feed causes pleat defects. Check roll alignment, tension, and smooth unrolling. Ensure the material is compatible with the machine’s specifications. Adjust guides and rollers for consistent feed. Additionally, inspect the media for wrinkles or tears. Consequently, resolving feed problems reduces jams and improves the quality of production. Maintaining proper material handling protects both the machine and filter integrity in Pleating Machines for Filters.

Blade and Die Wear

Dull or misaligned blades create uneven pleats or tears. Inspect blades for sharpness and signs of wear on a regular basis. Tighten or replace fasteners to maintain proper alignment. Lubricate moving parts as recommended by the manufacturer. Moreover, verify that the die settings match the pleat dimensions precisely. Regular replacement schedules prevent sudden failures. Thus, maintaining blades and dies ensures accurate and consistent pleating in Pleating Machines for the Filter.

Tension and Speed Control

Incorrect tension or speed leads to inconsistent pleats and scrap. Monitor belt tension, drive motor settings, and roller friction. Adjust speed gradually to match material and pleat density. Use sensors to automatically detect slack or over-tension. Additionally, train operators should be trained to respond promptly to any deviations from standard operating procedures. Therefore, proper control of tension and speed stabilises output quality and reduces downtime in Pleating Machines for Filters.

Alignment and Registration Errors

Misalignment causes uneven pleats or overlapping material. Inspect the guide rails, pleat-forming plates, and end stops. Use precision measurement tools to confirm correct registration. Recalibrate if necessary and test on scrap material first. Also, maintain clear markings for quick visual checks. Consequently, proper alignment ensures uniform pleat spacing and reduces defects. Consistent registration is critical for reliable operation in Pleating Machines for Filters.

Airflow and Vacuum Issues

Improper airflow or vacuum causes media misplacement or pleat collapse. Check suction lines, blowers, and filters regularly to ensure optimal performance. Adjust vacuum strength according to material thickness. Clean clogged vents and replace worn seals. Additionally, monitor air pressure gauges for fluctuations. Correct airflow and vacuum settings support accurate pleat formation, reducing rework. Reliable air handling protects both media and machine in Pleating Machines for Filters.

Operator Training and Best Practices

Skilled operators prevent many common issues. Provide structured training on setup, troubleshooting, and safety procedures. Encourage adherence to standard operating procedures (SOPs) to ensure a safe and efficient work environment. Conduct refresher courses regularly and review recurring errors. Promote awareness of subtle signs of wear or misalignment. Empower operators to take immediate corrective action. Consequently, well-trained staff improve efficiency and reduce defect rates in Pleating Machines for Filters.

Preventive Maintenance and Documentation

Regular maintenance reduces unexpected failures. Inspect mechanical, electrical, and pneumatic components on a schedule. Lubricate bearings, clean sensors, and tighten loose connections. Document maintenance activities and log issues for trend analysis. Schedule downtime for preventive checks rather than reactive repairs. This approach extends machine lifespan and ensures stable production. Consistent documentation strengthens operational reliability in Pleating Machines for Filters.

Troubleshooting Checklist for Pleating Machines for Filters

Effective troubleshooting encompasses a range of activities, including feed checks, blade maintenance, tension control, alignment, airflow management, operator training, and preventive maintenance. Regular inspections and real-time adjustments minimise defects. Maintaining accurate logs enables continuous process improvement. By following these guidelines, manufacturers ensure high-quality filter production with minimal downtime. Implement these practices to optimise efficiency and reliability in Pleating Machines for Filters.