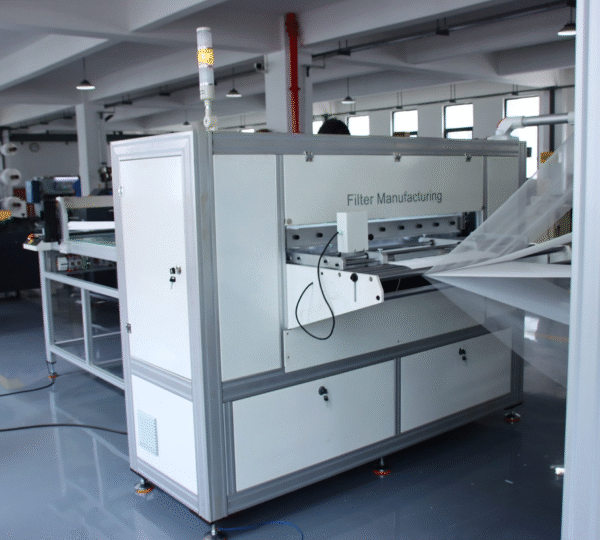

Paper pleating machines are the core production equipment in the filter manufacturing process. They transform flat filter media into uniform pleats to capture the smallest airborne particles. However, high-speed production lines encounter issues such as paper wrinkling and skew, which are often attributed to uneven tension, misaligned pleating rollers, and fluctuations in material feed speed. Traditional pleating machines rely on fixed roller positions and manual tension adjustment, which struggle to maintain consistency as production speeds increase. Dahe’s intelligent paper pleating machine overcomes these limitations with an integrated servo control system that dynamically adjusts the pleating height without physically changing the rollers.

At the same time, the feed mechanism uses a pneumatic shaft equipped with a scale to accurately position the material, while the magnetic powder brake maintains constant tension throughout the conveying process. The combination of these technologies ensures that the high-speed paper pleating machine runs smoothly and reduces the risk of wrinkling or skew during the pleat formation process.

Height adjustment with servo drive of the paper pleating machine for precise pleating

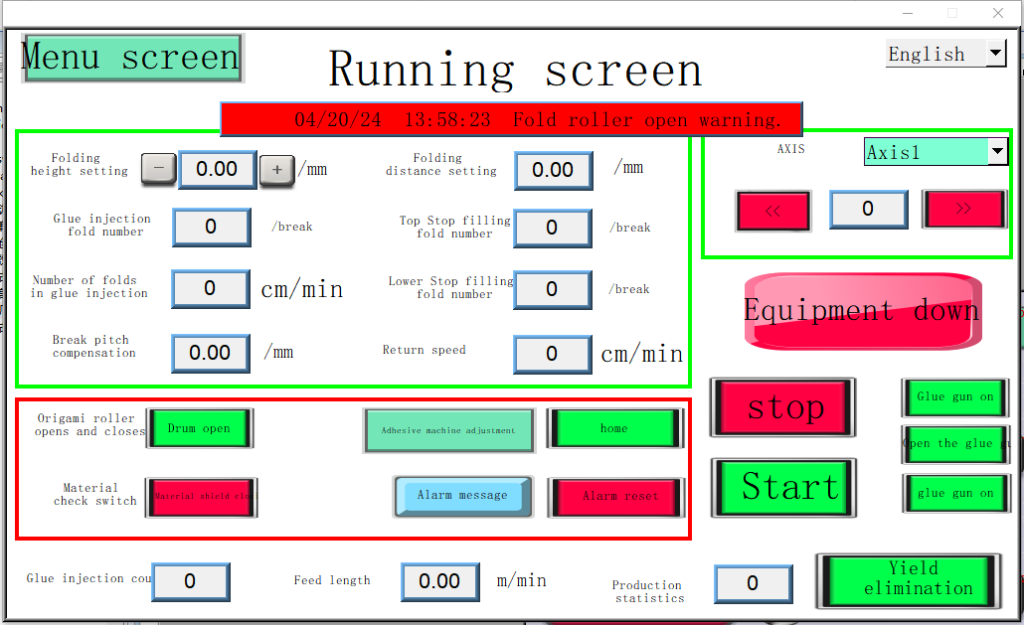

The core of Dahe’s high-speed paper pleating machine lies in its servo-driven pleating height adjustment function, which directly solves the problems of wrinkling and skew. Traditional pleating systems utilise fixed pleat rollers with preset heights, necessitating manual intervention and roller replacement whenever the pleat depth changes or when handling media with varying thicknesses. However, this approach introduces uncertainty: inaccurate roller replacement, alignment errors, and downtime during changeovers all lead to inconsistent pleat geometry and material deformation. In contrast, servo-motor-driven paper pleating machines dynamically control roller height, enabling real-time, software-defined adjustments without stopping production or physically replacing components.

By programming the pleat height trajectory in the control interface, operators can create recipe profiles for various pleat counts, filter media thicknesses, and pleat angles. This eliminates the need for manual roller changes and significantly reduces setup time between production runs.

The servo control system for the paper pleating machine enables smooth and reliable operation.

In addition to pleat height adjustment, the servo control system of Dahe paper pleating machines supports the entire pleating process, ensuring smooth material handling and synchronised motion of multiple axes. Two or more of these servo axes coordinate media feeding, roller rotation, and synchronized tension adjustment. Microsecond synchronization between the feed rollers, folding rollers, and downstream conveyor belts is achieved by utilizing a programmable logic controller (PLC) with real-time motion control capabilities. This precise coordination prevents momentary speed differences from causing material pulling, which can result in wrinkling or skewing.

In actual manufacturing scenarios, this servo-driven reliability translates into measurable benefits. After switching from a mechanical pleating system to a servo-driven paper pleating machine, the number of pleat defects was reduced by up to 40%. Additionally, the servo control architecture enables rapid recipe changes through the control interface, allowing for the instant call-up of feed speed, pleat height, and pleat angle. This minimises human error and ensures repeatable quality across filter grades.

Adjustable pleat height without roller replacement

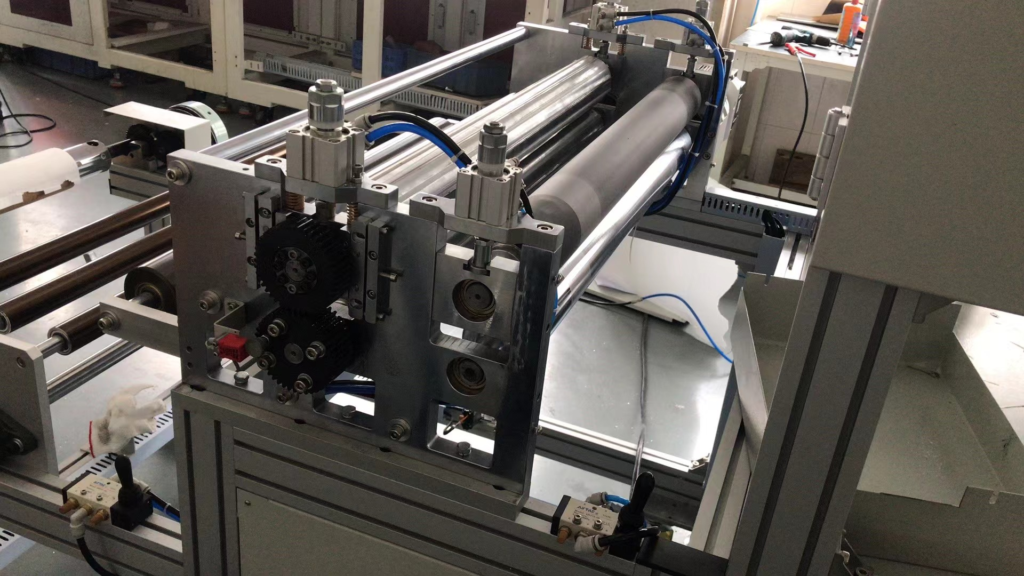

In many traditional filter media pleating machines, the pleating rollers must be manually replaced to accommodate different filter media thicknesses or pleat shapes—a process that requires downtime, manual adjustment, and subsequent readjustment. Each roller change can cause misalignment, often resulting in skewing pleats or inconsistent fold shapes. Dahe’s paper folding machine eliminates this laborious process with a servo-assisted, height-adjustable pleating roller assembly. The secret lies in the servo-driven vertical actuators integrated into each folding station. A high-precision ball screw and linear guide assembly connect the folding rollers to the servo motor for smooth, backlash-free position control.

This dynamic fold height feature not only reduces setup time but also increases production flexibility. Meanwhile, the control interface stores parameters for each media type, including fold height, feed speed, and tension settings. Quick submenu selection automatically adjusts the servo drive shaft to the appropriate position, ensuring consistent pleat quality downstream and reducing changeover time.

Pneumatic feed shaft with scale for material alignment

Continuous feeding of filter media also prevents wrinkling and skewing. Dahe’s paper pleating machines utilise an advanced feeding mechanism, where the drive shaft is pneumatic and equipped with a scale to precisely and controllably unwind the media roll. This pneumatic shaft offers two significant advantages over manual or friction-based feeding systems: quick roll changes without requiring manual adjustment of the roll core and precise media alignment with adjustable shaft end gaps. When changing media rolls, the operator slides the roll onto the pneumatic shaft, inflates the internal air bladder, and then locks the roll into place, ensuring concentric rotation and consistent lateral alignment.

In addition, the internal air pressure of the pneumatic shaft can be precisely controlled to adjust the radial clamping force of the roll’s inner diameter. Inconsistent clamping often causes the roll to move laterally during feeding, causing skew. Therefore, we fine-tune the compressed air to maintain enough friction to drive the roll without squeezing it. This creates a stable, wrinkle-free feeding environment.

Magnetic Powder Brakes for Tension Stability

We equip the folding machine shaft with magnetic powder brakes to maintain uniform tension regardless of the reduction in roll diameter. As the filter media passes from the pneumatic feed shaft into the pleated section, the media transitions from a full-diameter roll to a gradually shrinking roll. Without compensating for tension control, the press will slacken, causing wrinkles or tension that may potentially tear the material. The magnetic powder brake applies a variable torque to the feed shaft, automatically adjusting the force based on the roll’s rotational inertia. This ensures that the media is neither too loose nor too tight when unwinding, thereby minimising stress concentrations that cause wrinkling or skewing.

Additionally, the magnetic powder brake facilitates smooth acceleration and deceleration of the media roll. When the speed of the pleating section changes, the brake adjusts the torque to prevent sudden tension peaks. Because these peaks stretch the material, causing wrinkle deformation or micro-tears, it will appear wrinkled after folding.

Preventing wrinkles and skew

The paper folding machine integrates key technologies, including servo-driven fold height adjustment, a servo control system, a pneumatic feed shaft with an integrated scale, and magnetic powder brakes. It dynamically adjusts the position of the folding roller through the servo motor, eliminating the need for manual roller replacement. At the feed end, the pneumatic shaft with scale allows fast roll replacement and precise axial alignment, eliminating lateral offsets that cause skew. The magnetic powder brake ensures stable, adaptive tension control, automatically compensating for changes in roll diameter and line speed. Together, these mechanisms form a tightly coupled system that reduces wrinkling or skewing.