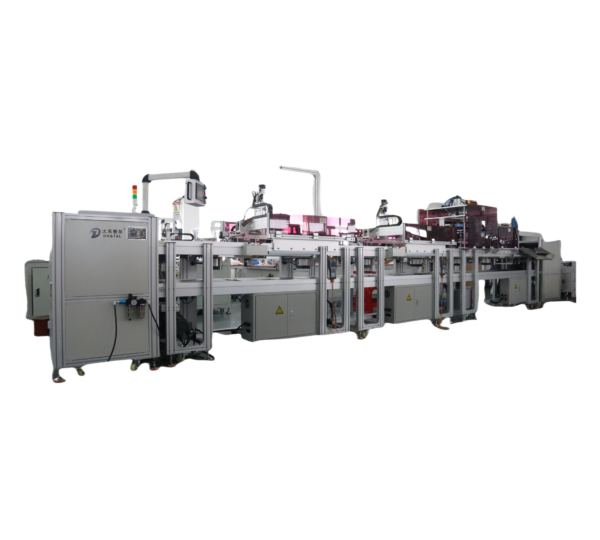

The automatic HEPA filter assembly line provided by Dahe Intelligence usually integrates two three-axis dispensing mechanisms to apply glue to the upper and lower surfaces of the HEPA frame respectively. After using the adhesive, the two halves of the HEPA filter are automatically pressed together. To accelerate adhesive curing and stabilize viscosity, the production line is also equipped with a cooling water circulation device that quickly reduces the glue temperature, resulting in a rise in viscosity and rapid solidification of the adhesive. This interaction between dispensing accuracy and thermal management helps minimize adhesive diffusion, shorten cycle time, and prevent misalignment, thereby optimizing the change in glue viscosity.

Adhesive rheology and viscosity issues for automatic HEPA filter assembly lines

Automatic HEPA filter assembly lines still use adhesives formulated for high-efficiency filtration applications. These adhesives must remain viscous enough to bond metal or plastic frames without penetrating delicate filter media. Most HEPA adhesives are polyurethane or epoxy-based adhesives, whose viscoelastic properties change significantly under shear and temperature fluctuations. When heated, the glue becomes thinner, which reduces the cohesion of the glue bead and increases the risk of adhesive exudation. Conversely, at lower temperatures, thickened glue can clog the nozzle tip or fail to form a continuous glue bead. This dual sensitivity results in a narrow viscosity operating window, typically ranging from 500 to 1,200 cP at dispensing temperature.

Precision Dispensing with Dual Three-Axis Mechanisms on an Automatic HEPA Filter Assembly Line

On automated HEPA filter assembly lines, the precise application of adhesive directly impacts final filter performance. We integrated two three-axis dispensing mechanisms, one for the upper surface of the HEPA frame and one for the lower surface, to ensure symmetrical glue distribution. Each three-axis gantry features X, Y, and Z motion stages driven by stepper motors and linear guides, enabling repeatability within ±0.02 mm. The gantry executes a synchronized motion profile that lays adhesive beads simultaneously along the perimeter, and the system calibrates dwell times to deposit 0.2 to 0.5 grams of adhesive per linear meter.

To counteract minor viscosity fluctuations, each dispensing module integrates a feedback loop between a motor-driven peristaltic or gear pump and an inline flow sensor. The system automatically adjusts the pump’s speed to maintain a consistent volume flow and compensate for viscosity-induced resistance within the adhesive column. Additionally, the three-axis Z-axis insertion depth ensures that the nozzle tip hovers 0.5 mm above the frame surface, preventing adhesive smearing while maintaining sufficient contact to form a glue bead.

Rapid viscosity stabilization through cooling water loop

A key innovation of the automated HEPA filter assembly line is the installation of a cooling water loop just below the conveyor section where the filter frames pass immediately after glue application. This closed-loop cooling water loop circulates cooling water to remove heat from the newly applied glue bead quickly. As the glue transitions from a liquid to a semi-solid state, its viscosity rapidly increases from the glue application parameters of 500-800 cP to a near-solid viscosity of 2,000-3,000 cP in 10-20 seconds. This rapid viscosity stabilization mechanism prevents adhesive from penetrating the pleated packaging. It ensures a precise and uniform seal around the filter perimeter, significantly reducing rework due to adhesive misalignment or smearing.

By integrating this cooling water mechanism, the automated HEPA filter assembly not only suppresses viscosity changes but also accelerates the initial curing phase of the adhesive, allowing subsequent processing stations to proceed promptly and thereby maintaining high production output.

Real-time monitoring and control of glue temperature

Operators must continuously monitor the glue temperature on the automated HEPA filter assembly line to maintain optimal adhesive viscosity. We utilize a network of precision temperature sensors, including RTD or PT100 probes, embedded in the glue reservoir, feed line, and dispensing nozzle. These sensors transmit temperature data to the central Programmable Logic Controller (PLC). If the glue reservoir temperature deviates from the set point, the system automatically adjusts the heater’s power output to maintain the temperature within ±1°C. At the same time, the built-in infrared sensor at the dispensing nozzle verifies that the glue is at a constant temperature before contacting the frame.

Any unexpected changes will trigger an alarm and automatically stop the production line to prevent filter seal defects. To this end, Dahe Intelligent has equipped the automated HEPA filter assembly line with insulated manifolds and pre-insulated hoses to cope with rapid changes in ambient temperature. These components can reduce the loss or gain of conductive heat.

Maintenance, calibration and best practices

Optimizing glue viscosity also requires maintenance and regular calibration. Regular inspections, conducted every two weeks, should include checking the glue reservoir for residual polymer and removing any partially cured glue using recommended cleaning solvents. Additionally, the nozzle tip should be ultrasonically cleaned to remove any tiny glue residues that may alter the geometry of the glue bead. RTD and nozzle thermocouples require quarterly calibration using a precision dry body calibrator to ensure temperature accuracy. Technicians should maintain the cooling circuit by flushing the coolant and replacing the scale filter every six months to ensure optimal heat exchange efficiency. By adopting these best practices, Dahe’s intelligent automatic HEPA filter assembly line can continuously provide high-quality, leak-proof initial seals, minimize scrap rates, and maintain productivity of more than 120 filters per hour.

Ultimately

To better optimize the glue’s viscosity, engineers must integrate precise temperature control, real-time monitoring, advanced dispensing mechanisms, and strict maintenance procedures. Two three-axis dispensing mechanisms perform the dispensing on the upper and lower sides of the HEPA frame. A cooling water circulation device quickly solidifies and cools the glue, ensuring the product adheres firmly and responds effectively to changes in glue viscosity.