Long production runs expose every weakness in setup, process, and maintenance. Even small errors can build into major rejects. A servo-driven pleating machine can maintain a repeatable pitch only when calibration, tension, and operating conditions remain consistent throughout its operation. Accuracy depends on both the hardware and the discipline of the team running it. With careful preparation, environmental control, data monitoring, and timely maintenance, you can maintain high quality and minimize scrap, even on demanding schedules.

Calibrate and Align Before Every Run

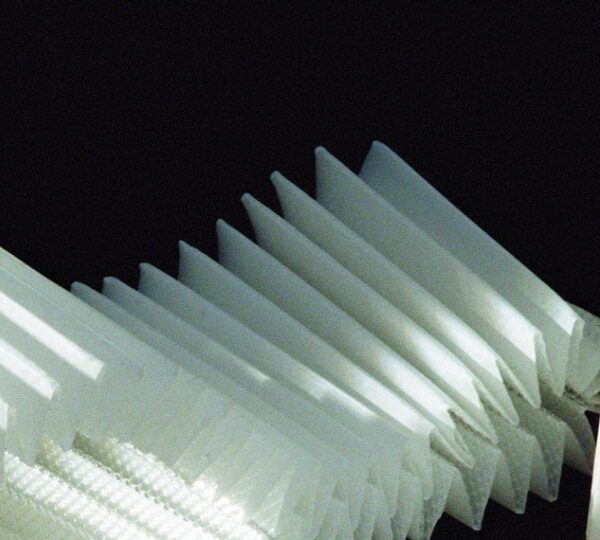

Start each run with a structured calibration routine on the Paper pleating machine. Warm up the motors to stabilize temperature and torque output. Verify encoder counts, knife timing, and home positions against reference marks to ensure accuracy and consistency. Measure the pleat depth and pitch using certified gauges and compare them to the engineering specifications. If there is any variation, adjust backlash compensation, feed factors, and knife position before running production. Lock all fixtures, check parallelism on guides, and tighten all fasteners to the correct torque. Record final setup parameters on a setup sheet or in the machine’s control system so the next operator can replicate your results without guesswork.

Control Web Tension and Feed Stability

Tension control is critical for accuracy. Install and regularly calibrate load cells, dancer arms, or other feedback devices on the servo-driven pleating machine to maintain steady unwind tension. Retune PID parameters as material rolls get smaller to avoid feed surges. Anti-static bars help prevent cling that can affect material tracking. Keep all feed rollers clean and free of adhesive buildup that can cause slippage. Check edge guides to ensure proper alignment and prevent the sheet from drifting during pleating. Confirm that slip clutches maintain stable torque without overheating, which could cause drift and misalignment.

Manage Thermal Stability Throughout the Run

Temperature affects both the material properties and the servo-driven pleating machine’s motion control accuracy. Monitor motor, gearbox, and cabinet temperatures during production to ensure optimal performance. Clean fans, replace filters, and ensure air vents are clear of obstructions to maintain optimal airflow. On high-speed or high-load jobs, schedule short cool-down intervals to prevent heat buildup. Utilize torque derating alarms in the control system to prevent the drive from exceeding its rated load. After extended pauses or lunch breaks, run a short “thermal settle” sequence to stabilize material and drive components before resuming production. Recheck the knife-to-anvil clearance after temperature changes to maintain consistent cut accuracy.

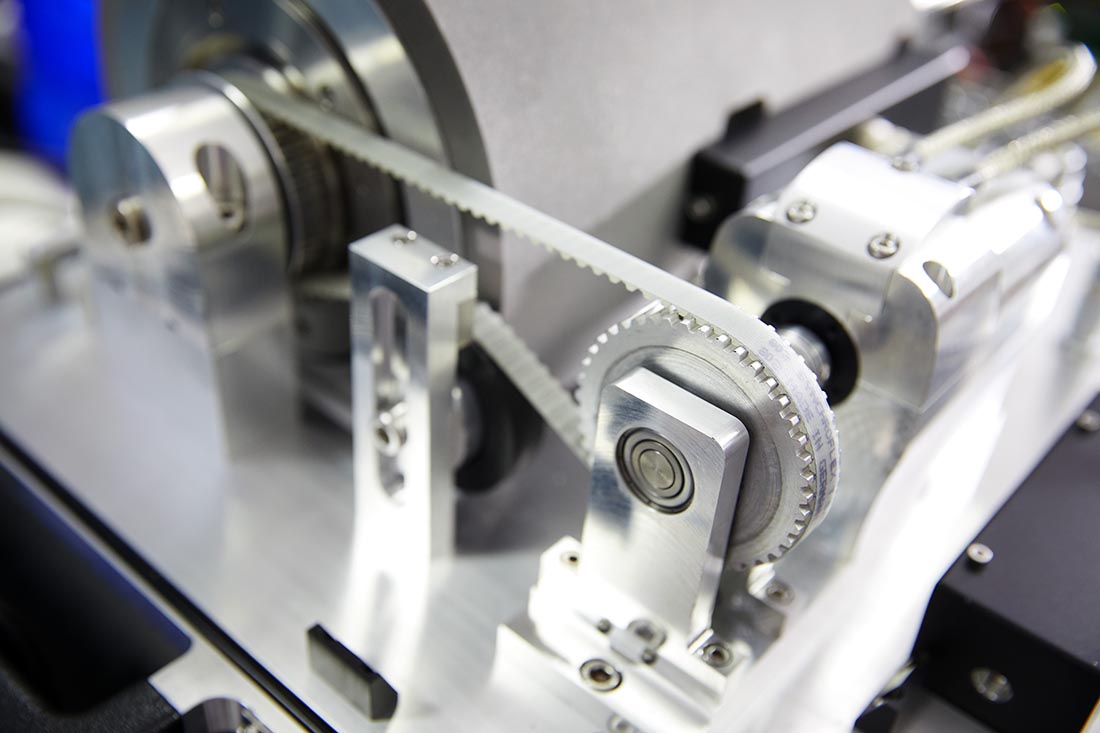

Maintain Motion Components in Peak Condition

Friction, wear, and contamination can quickly degrade performance. Clean linear guides, rails, knives, and cams regularly, using only the manufacturer’s approved lubricants and following the recommended intervals. Remove dust, fibre fines, and adhesive mist from sensors to prevent false readings. Inspect belts for glazing, cracks, or uneven wear, and maintain correct belt tension. Replace worn bushings or bearings before excessive play develops. Use a torque wrench to confirm fasteners hold their proper preload. These actions maintain the motion’s smoothness, enabling the servo-driven pleating machine to deliver consistent pleat geometry.

Leverage Data and Early Warning Systems

Your machine’s PLC or control software is a valuable tool for protecting accuracy. Configure SPC charts to track pitch and pleat depth in real time. Set tight process limits so the system alerts operators before defects occur. Keep logs of cycle counts, micro-stops, and scrap causes to track and analyze performance. Utilize barcode or RFID job tracking to associate production data with specific materials and operators. Review CPK and PpK metrics weekly and take immediate action on any negative trends. This approach enables addressing issues while they are still small and before they impact a significant portion of a production batch.

Train Operators for Discipline and Rapid Checks

Even the best servo-driven pleating machine needs skilled operators to maintain accuracy. Train staff to recognize early signs of trouble, such as wear patterns, faint alignment marks, or subtle changes in tension. Standardize quick checks at the start, during, and at the end of each run. Provide go/no-go gauges, inspection templates, and visual references so checks are fast and consistent. Encourage operators to stop the machine immediately when in doubt, without penalty, to prevent downstream problems. Keep simple checklists for breaks, roll changes, and shift handovers to ensure nothing is missed during the transition.

Implement Structured Preventive Maintenance

Preventive maintenance ensures high accuracy over the long term. Create a maintenance calendar for knives, belts, encoders, and bearings that is specific to your servo-driven pleating machine’s workload. Stock spare parts that can prevent extended downtime, including drives, sensors, couplings, and cooling fans. Schedule alignment audits to catch frame or guide deviations early. Back up firmware and control parameters regularly in case of hardware failure. After each major service, run a short capability study to confirm the machine is performing within specification. Consider upgrading to higher-resolution encoders or improved tension control modules if your production demands even tighter tolerances.

Long-Term Accuracy Strategies for Servo Driven Pleating Machines

Maintaining peak accuracy during extended production is not a matter of luck; it is the result of process discipline, environmental stability, and proactive maintenance. Every step—from precise calibration to active tension control and thermal management—protects product quality. Data-driven monitoring and operator training reduce human error, while preventive maintenance keeps the servo-driven pleating machine in top form. By applying these strategies consistently, you extend machine life, minimize scrap, and deliver uniform products even under the pressure of long, continuous runs.