In traditional glue injection lines, operators often manually lift and position materials, resulting in inconsistent cycle times and fatigue-related errors. In contrast, the fully automatic fiberglass origami glue injection line integrates automatic feeding, precision control systems, and user-friendly interfaces to streamline every stage of production. Manual operation not only slows down your production cycle but also causes material position changes, which affects injection accuracy. With automatic feeding, automation features such as central touchscreen control can improve the operational efficiency of the fiberglass origami glue injection line.

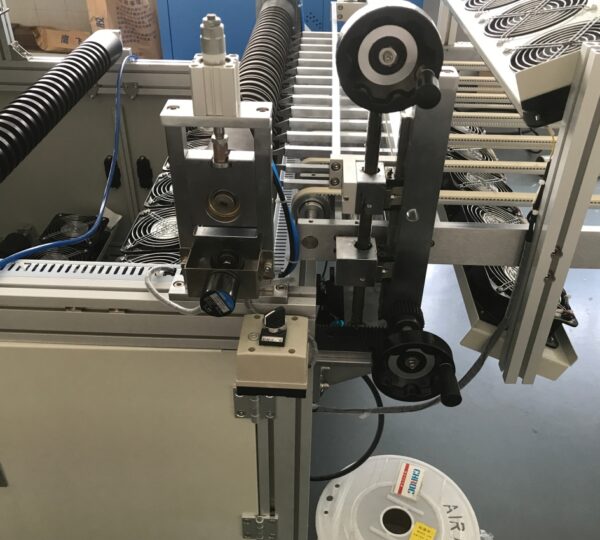

Automatic feeding function of the fiberglass origami glue injection line

In traditional equipment manufacturers, operators must lift the folded fibreglass board to the unloading position, which wastes not only valuable cycle time but also risks uneven glue coating. By integrating automatic feeding, you can eliminate this manual step, allowing the line to run continuously without operator intervention. The automatic feeder picks up a single fiberglass board, positions it precisely under the glue injection nozzle, and then conveys it downstream.

Additionally, automatic feeding reduces ergonomic burdens and minimizes human error. Instead of changing lift height or accidentally re-feeding, the system delivers each sheet in a consistent position and orientation. As a result, your fiberglass dispensing line can achieve higher repeatability, better adhesive distribution, and fewer defective parts for more efficient operations.

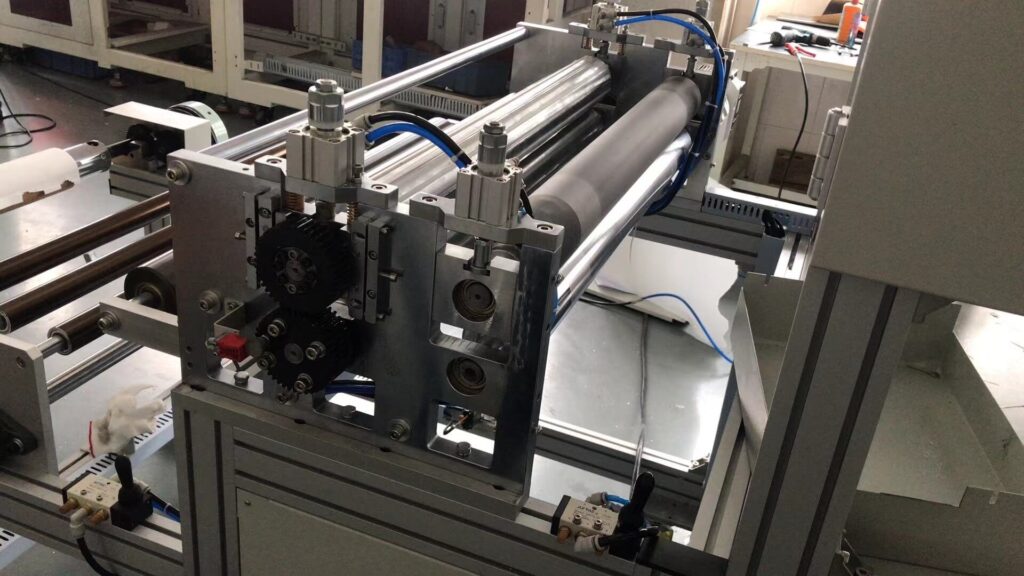

Equipped with an inflatable feed shaft for quick material changes

Material switching can impact the efficiency of your dispensing line, particularly when switching between fibreglass sheet sizes or thicknesses. That’s why we use an inflatable feed shaft, which simplifies roller changes and eliminates the need for time-consuming mechanical adjustments. In this setup, the feed shaft inflates to grasp the material firmly. When deflated, it releases instantly for quick roller changes, reducing changeover time from hours to minutes.

Additionally, the inflatable shaft accommodates subtle changes in roll diameter and core size, ensuring constant feed pressure without requiring manual tightening. In contrast, traditional inflatable shafts require manual removal of end caps and precise installation of new rolls, which often results in misalignment and material tilting. With the inflatable shaft design, you can complete the operation by pressing a button on the touchscreen interface.

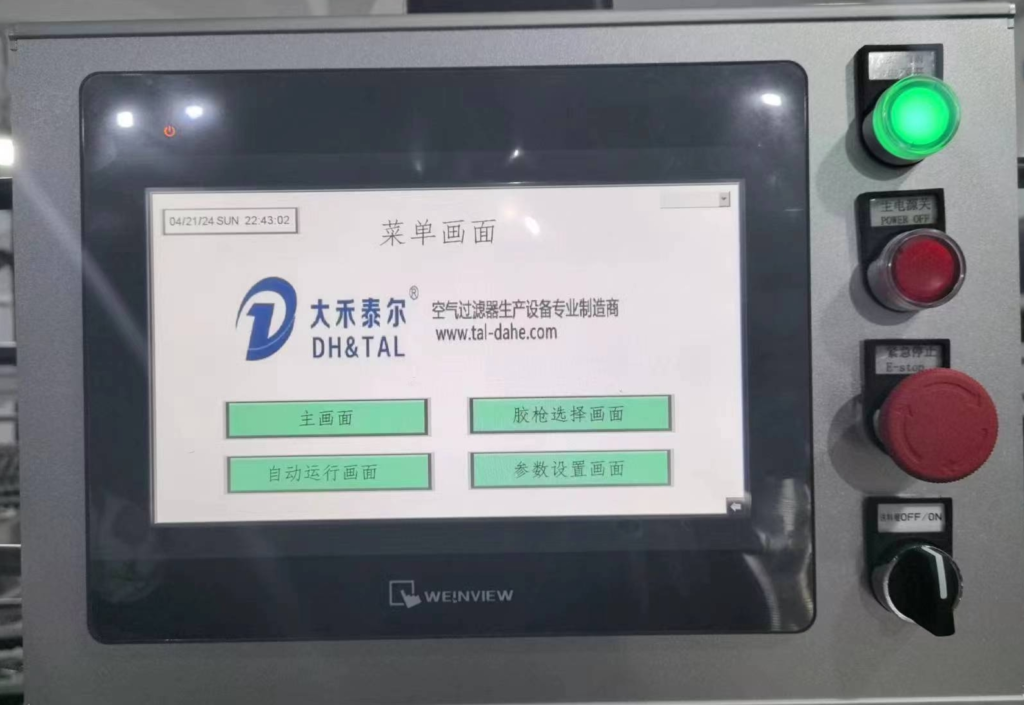

Synchronization of folding and conveyor speeds on the fiberglass origami glue injection line

On fiberglass origami glue injection lines, you can synchronise the folding unit and conveyor belt through a central touchscreen controller. By coupling the speed of the folding rollers to the conveyor belt servo motor, each sheet is fed out at precisely the same speed and time, eliminating bottlenecks and feeding errors. In practice, you can set a target sheet spacing, such as 150 mm, directly on the screen. The system automatically adjusts the folding speed and conveyor belt rate to maintain that spacing, even if you change the cycle time or material thickness. This synchronisation can enhance the efficiency of equipment production operations by minimising scrap resulting from overlapping sheets or eccentric injection.

Sheet spacing and folding height adjustment

Flexible sheet spacing and folding height are crucial when your line must accommodate a range of fiberglass sheet sizes. You can adjust these two parameters via a touchscreen interface without having to change the folding rollers. The folding depth is adjusted to match the sheet thickness by driving the stepper motor actuator to raise or lower the folding rollers. At the same time, you only need to enter the desired sheet spacing, and the conveyor belt speed will be adjusted accordingly.

Additionally, software-controlled adjustments eliminate the need for manual measurements and trial-and-error settings, reducing format change time by up to 70%. This feature ensures that each sheet spends the same amount of time under the glue injection head, preventing both over- and under-glueing. By leveraging the touchscreen to control pitch and fold height, you can maintain high precision while significantly increasing the versatility of your line.

Maintain your equipment with efficiency

In addition to leveraging its automation features, maintaining optimal efficiency requires a proactive maintenance plan for your fiberglass origami glue injection line. First, schedule daily inspections of the air-filled feed shafts to check air pressure and shaft surface wear, ensuring rapid inflation and deflation. Next, clean the folding rollers and conveyor belts every week to prevent adhesive buildup, which can affect friction and sheet spacing. Additionally, calibrate the position sensors of the touchscreen controller monthly and verify the servo motor encoders to maintain synchronisation accuracy. Meanwhile, monitor key performance indicators (KPIs) such as feed rate consistency, cycle time variance, and the number of rejects. By analyzing trends, you can detect bearing wear or sensor drift before they cause unplanned downtime, ensuring that the glue injection line runs smoothly.

Bring high operating efficiency to glue injection production

To enhance the operating efficiency of the fiberglass origami glue injection production line, we have integrated automation, flexible material handling functions, and effective maintenance measures. The automatic feeding function eliminates the need for manual lifting and can standardize the feeding rate. At the same time, the use of an inflatable feeding shaft simplifies the material change process, while the touch-screen-controlled folding and conveyor speed synchronisation function ensures accurate glue application. Additionally, the sheet spacing and folding height can be adjusted on the touchscreen, thereby improving versatility and increasing operating efficiency without compromising accuracy.