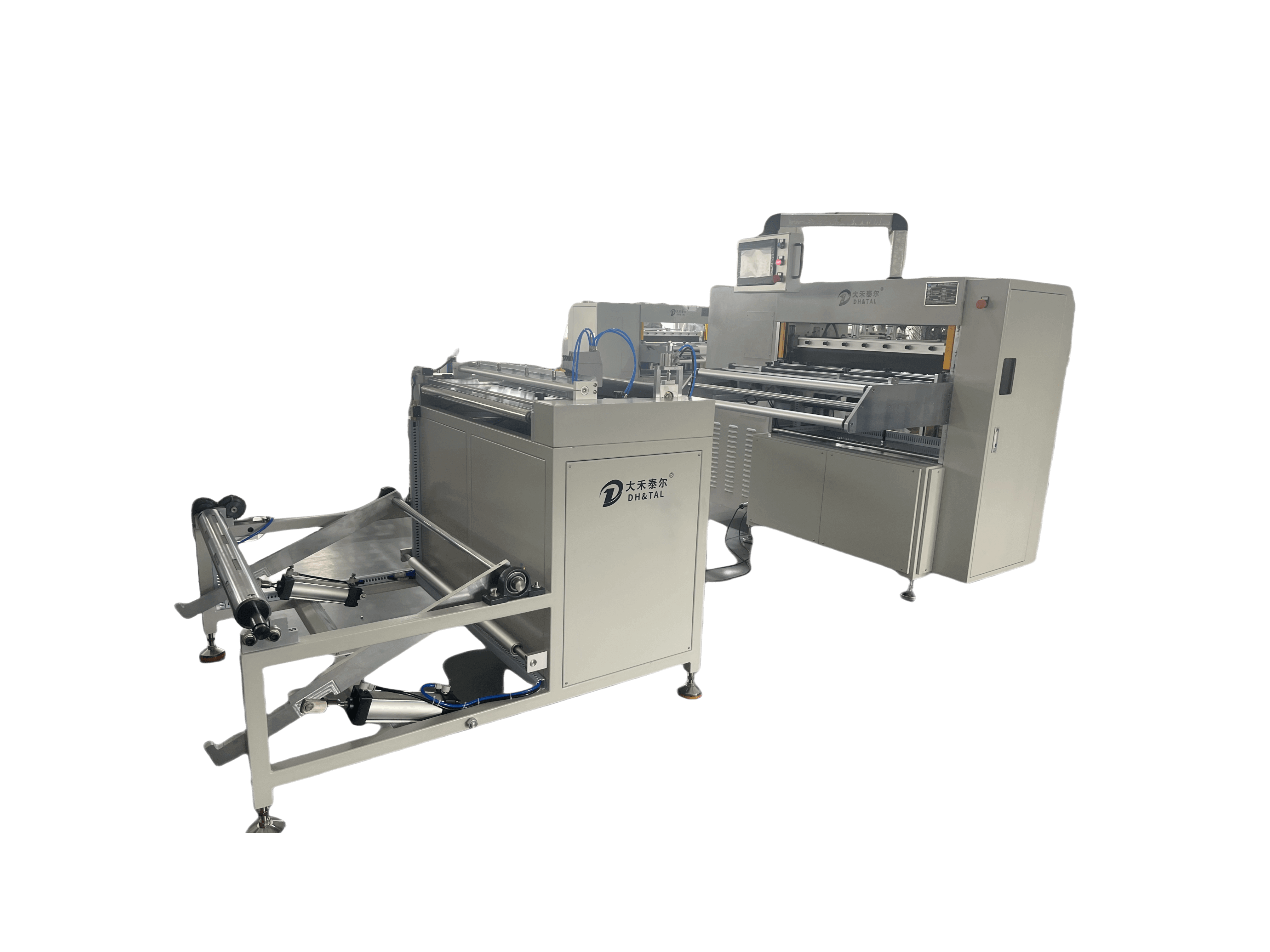

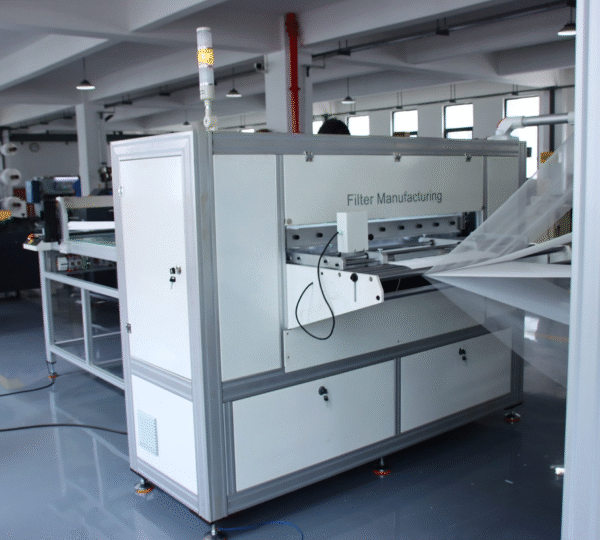

The pleating process directly impacts the efficiency and performance of filter paper production, and achieving precise folds with varying filter paper thicknesses, sizes, and materials is a challenge. A filter paper pleating machine powered by laser technology addresses this challenge. Lasers provide non-contact, high-precision measurement and control, resulting in more consistent results and minimizing errors in the pleating process.

The Impact of Laser Technology on Pleating Precision

Unlike traditional methods, which use mechanical adjustments and sensors to control pleating, lasers can measure the distance between pleats with extreme accuracy. This eliminates the guesswork involved in manual adjustments, resulting in uniformity and consistency across every batch.

Moreover, lasers are capable of continuous monitoring. As the Filter Paper Pleating Machine operates, the laser scans the pleats in real-time, detecting any variations or misalignments. These deviations can be instantly corrected by adjusting the machine’s settings, ensuring that the pleats remain consistent throughout the production process. This significantly reduces the likelihood of errors, wastage, and rework.

Enhanced Speed and Efficiency with Laser Technology

One of the key benefits of incorporating laser technology in the pleating process is the increased speed at which the machine operates. Traditional pleating machines often require manual intervention to check pleat consistency, which can slow down production. Lasers automate the entire pleating process by constantly adjusting the machine to maintain precision.

The Filter Paper Pleating Machines, equipped with laser technology, can process large volumes of paper quickly without compromising the quality of the pleats. This increased efficiency is crucial in high-demand manufacturing environments where time and cost are critical factors. Moreover, with fewer interruptions for adjustments or recalibrations, the machine operates at a more consistent pace, resulting in reduced downtime and improved overall throughput.

Real-Time Monitoring and Error Prevention

Laser technology enables the real-time monitoring of pleating accuracy, preventing errors before they impact the final product. By using laser sensors to measure the pleat depth, spacing, and alignment constantly, manufacturers can detect issues early in the process. This proactive approach allows for immediate corrective action, ensuring that the pleats remain within the required specifications.

In addition to detecting misalignments, laser systems can also identify irregularities in paper thickness or other material properties that could affect pleat consistency. The Filter Paper Pleating Machine can be adjusted accordingly, preventing issues like over- or under-pleating that can lead to faulty filters. This real-time error detection helps minimize waste, reduce scrap rates, and ensure that only the highest-quality product reaches the market.

Improved Customization and Flexibility for Different Materials

The ability to easily adjust settings on the Filter Paper Pleating Machine using laser technology is beneficial when working with different types of filter papers. Paper thickness, material type, and texture can vary significantly, making it challenging to achieve consistent pleating without precise adjustments. A laser system automatically makes these adjustments, offering greater flexibility and customization for different production needs.

For instance, when switching from a thicker to a thinner filter paper, the laser System can adjust the machine’s settings to ensure the pleats remain consistent in depth and spacing. This capability significantly reduces the need for manual recalibration, saving time and ensuring that no compromise is made on pleat quality, regardless of the material being used.

Reducing Waste and Improving Yield

Laser technology helps reduce waste by improving the consistency of pleats and minimizing errors. Traditional pleating methods often lead to paper wastage due to incorrect pleat depth or alignment. By integrating lasers, the Filter Paper Pleating Machine becomes significantly more precise, reducing scrap rates and increasing the proportion of paper used in production that is transformed into high-quality pleated filters.

With fewer errors and less material wasted, manufacturers can achieve higher yields, ultimately improving the profitability of the production process. This is especially important in large-scale manufacturing, where reducing waste has a direct impact on the bottom line.

Cost Efficiency Over Time

While the initial investment in laser technology for a Filter Paper Pleating Machine may seem high, the long-term savings make it a cost-effective choice for manufacturers. The waste reduction, fewer production delays, and increased machine efficiency all contribute to lowering overall operational costs. Additionally, the improved accuracy and speed result in more finished products in less time, further driving cost savings.

Laser technology also helps reduce the need for manual labor, as the machine is capable of making real-time adjustments without human intervention. This reduces labor costs and frees up operators to focus on other tasks, improving workforce productivity and further decreasing production costs over time.

Unlocking the Full Potential of Your Filter Paper Pleating Machine

Integrating laser technology into the Filter Paper Pleating Machine yields clear benefits in terms of precision, efficiency, and cost reduction. Lasers enable real-time monitoring, error detection, and automatic adjustments, ensuring accurate and consistent pleating, regardless of material type or production speed. This leads to faster production, less waste, and higher yields, which ultimately help reduce operational costs.