As global demand for air and liquid filtration continues to grow, driven by the automotive, HVAC, and industrial sectors, filter manufacturers in these sectors need to work with filter production equipment manufacturer who understand the details of modern filter media, pleat geometries, and assembly processes. Top filter production equipment manufacturers provide filter production equipment and consulting guidance on designing coherent production processes, including adjustable depth media pleating lines for HEPA filter panels and automatic glue injection lines for HEPA filter assembly.

Proven expertise and industry experience in filter production equipment manufacturer

The depth of their industry experience is essential when evaluating filter production equipment manufacturers. Demonstrated expertise in core processes, including media pleating, header assembly, sealing, and robotic inspection, shows the manufacturer can anticipate challenges such as media tension changes or adhesive compatibility. Dahe Intelligent, as a filter production equipment manufacturer with decades of experience, has different case studies where we optimized the adjustable depth media pleating line for HEPA filter panels to achieve ±0.1 mm pleating accuracy or their automatic glue injection line for HEPA filter assembly reduced adhesive waste by 20%. By partnering with an experienced filter production equipment manufacturer, you can leverage best practices, proven machine architectures, and process expertise to reduce risk and accelerate time to market significantly.

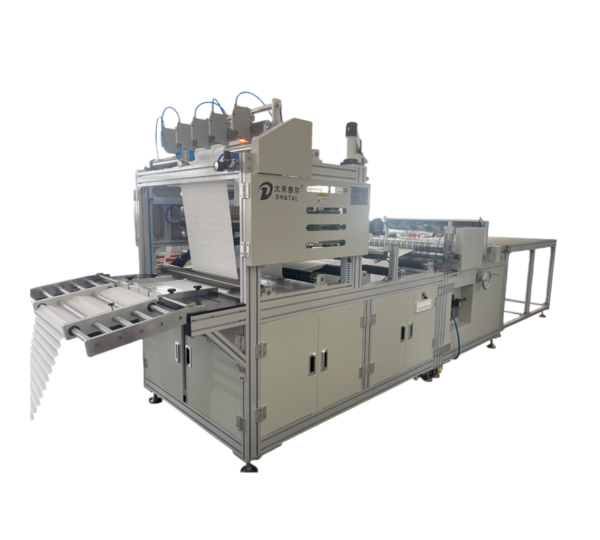

Filter Production Equipment Manufacturer Core Equipment Capabilities – Media Pleating Line

The heart of any high-efficiency production line lies in the media pleating stage. Adjustable depth media pleating lines for HEPA filter panels must handle fine filter media without creases or tears. As a filter production equipment manufacturer, we use servo-driven feeders, dual-wheel pleating heads, and in-line tension control to achieve consistent pleat height (e.g., 8 mm to 15 mm) and quantity. At the same time, advanced production lines are equipped with quick-change tools to change pleat profiles within 10 minutes, minimizing downtime during product changeovers. Sensor feedback loops monitor pleat depth and media feed speed, automatically correcting drift to maintain a tolerance of ±0.05 mm. In addition, when evaluating potential suppliers, request a live demonstration of the pleating line and request verification of its metrics, such as maximum throughput, consistency between pleats, and ease of integration with downstream processes such as ultrasonic welding or end cap bonding.

Automation Integration

When individual filter production equipment can be seamlessly integrated, efficiency is multiplied. Filter production equipment manufacturers should provide different customized solutions, such as an automated glue injection line for HEPA filter assembly that applies a precise bead of glue to the edge of the filter media before robotic cover placement. Automation modules may include vision-guided robots to ensure exact component alignment and servo-driven dispensers to adjust flow rates based on temperature and humidity. Integrated control systems are often based on PLCs to provide centralized monitoring to capture real-time metrics such as adhesive usage, cycle time, and process alarms. This level of automation and integration minimizes manual operations, reduces human error, and ensures consistent, high-quality output from the filter production line.

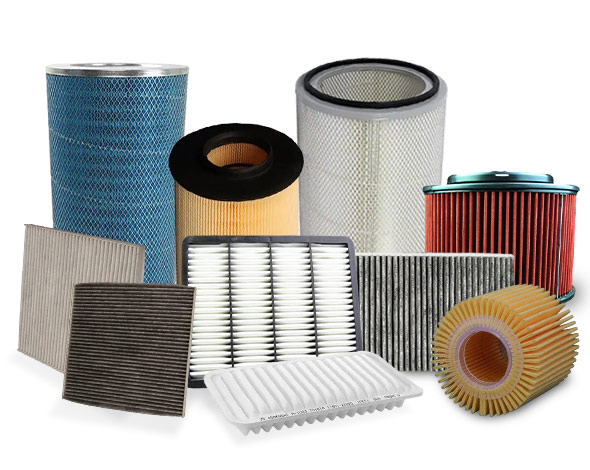

Customization and flexibility for different filter types

Every filtration application has unique requirements – a pleated filter element for HVAC, a filter for automotive cabin air, or a flat HEPA filter for a semiconductor clean room. Reputable filter production equipment manufacturers must provide deep customization options, allowing you to customize the media pleat line with adjustable depth to handle different filter sizes, pleat patterns, and assembly sequences. At the same time, manufacturers can quickly reconfigure modular designs by using interchangeable pleating wheels, adaptive fixtures, and programmable glue nozzle arrays. In addition, working with manufacturers who provide in-house prototyping and trial runs can help verify equipment settings for new filter media or innovative pleat geometries, ensuring that your production line can remain flexible as market demand changes.

Total Cost of Ownership and Return on Investment

While upfront capital expenditures are key considerations, the objective criteria for measuring cooperation with filter production equipment manufacturers are the total cost of ownership and return on investment. Efficient production lines generally include strategies such as servo automation and energy-saving drives. Usually, it reduces operating costs by 20-40% compared to traditional equipment. When calculating the return on investment, we should consider reduced labor requirements, reduced energy consumption, minimized material waste, and shortened payback periods by increasing output and maintaining quality consistency. Choosing a filter production equipment manufacturer that values life cycle value will enable you to improve long-term profitability and maintain a competitive advantage in the rapidly evolving filtration market.

Cooperation in High-Efficiency Filter Manufacturing

In seeking a high-efficiency filter production line, choosing the proper filter production equipment manufacturer is as important as selecting the filter material. Every element must work together, from the precision of the adjustable depth filter media pleating lines for HEPA filter panels to the seamless operation of the automated glue injection line for HEPA filter assembly. By evaluating suppliers for their expertise, equipment capabilities, automation integration, and flexibility in custom services, you can ensure maximum uptime for your investment.