In the production of HEPA filters, achieving optimal paper tension is critical to ensuring the quality and efficiency of the pleating process. Any inconsistency in paper tension as the pleating machine shapes the filter paper can result in defects, reduced product performance, or material waste. Achieving optimal paper tension requires a proper balance between machine settings, component specifications, and real-time adjustments. Dahe Intelligent’s HEPA filter paper pleating machine uses advanced features such as automatic tension control, precision rollers, and a powerful feedback loop to maintain consistent tension during the production process. This article will explore in detail how Dahe Intelligent’s intelligent pleating machine ensures optimal tension control, thereby improving the production of high-quality HEPA filters.

The Importance of Optimal Paper Tension in HEPA Filter Production

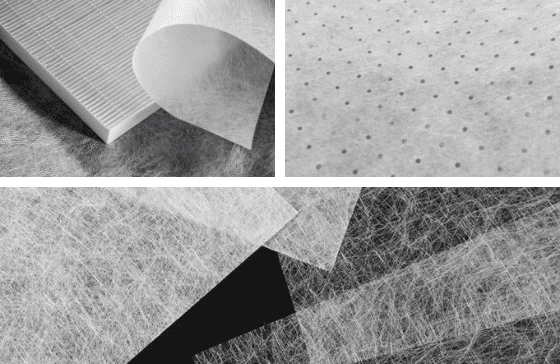

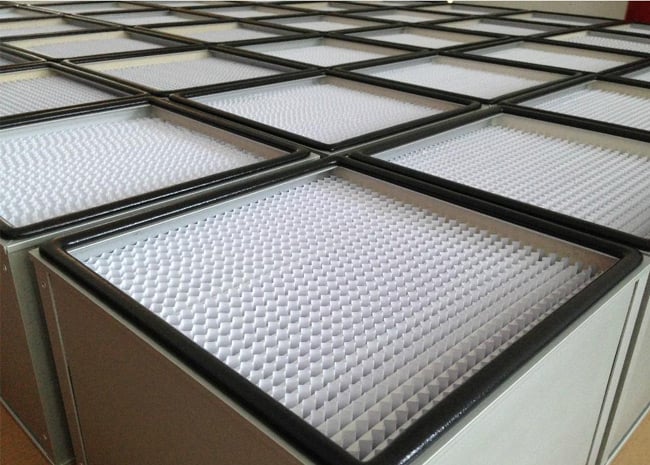

For the following reasons, maintaining optimal paper tension is critical when producing HEPA filters. First, proper paper tension ensures that pleats are uniform and precise, which directly affects the efficiency of the filter. Uneven tension can cause wrinkling or misaligned folds, which can reduce the performance and life of the filter. Second, maintaining consistent paper tension ensures efficient use of filter paper, thereby minimizing waste. If the paper tension is too high, it may tear or stretch, resulting in material waste. For HEPA filters, which require fine filtration and are used in sensitive applications such as air purifiers, the quality of the pleats directly affects the filtration efficiency. The pleats must be evenly spaced and always aligned to maximize the surface area and enhance airflow, which is critical to the performance of the filter.

How does Dahe’s intelligent HEPA filter paper pleating machine maintain optimal tension?

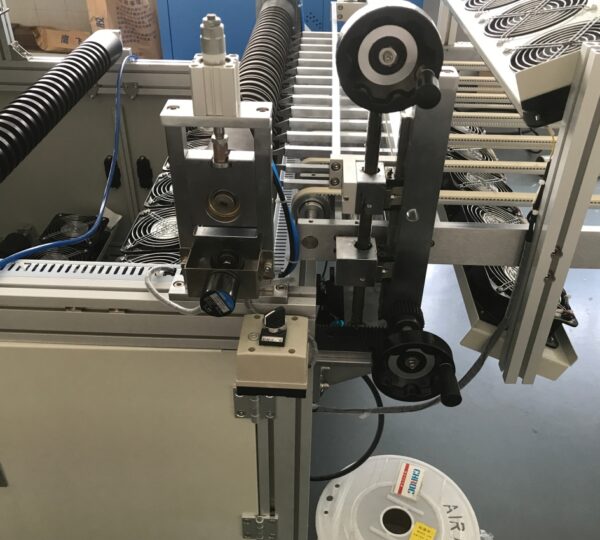

Dahe’s HEPA filter paper pleating machine features an advanced automatic tension control system that maintains constant tension on the filter paper during the pleating process. The system uses sensors and actuators to detect tension changes and make real-time adjustments to maintain uniform tension on the paper. It is also able to sense changes in paper thickness, humidity, and other environmental factors that may affect tension through dynamic response to ensure that the paper is always under appropriate pressure.

At the same time, the HEPA filter paper pleating machine comes with precision rollers that technicians calibrate to ensure uniform tension distribution. These rollers apply uniform pressure to the paper as it passes through the machine to prevent excessive tension in local areas. With this setting, the pleating process becomes more controllable, reducing the risk of defects such as wrinkling, misalignment, or poor pleat formation. In addition to maintaining tension, speed, and pressure can be precisely adjusted, optimizing the entire pleating process.

The role of feedback loops in ensuring consistent paper tension

A key feature of Dahe’s HEPA filter paper pleating machines is their feedback loop system, which continuously monitors the paper’s tension and instantly adjusts the machine’s settings to correct any fluctuations. This dynamic response ensures that the machine always maintains the optimal balance between speed, pressure, and tension.

If the machine detects a slight drop in tension, the feedback system will signal the automatic tension control system to increase the pull on the paper to restore tension to the optimal level. Conversely, if the tension is too high, the system will reduce pressure to prevent over-stretching of the material. The feedback loop operates continuously throughout the pleating process, processing any subtle changes in real-time and resulting in high-quality pleats with minimal defects. This closed-loop control system eliminates the need for manual adjustments, reduces downtime, and minimizes waste, thereby improving overall efficiency.

The benefits of precision rollers for pleating machine tension control

Precision rollers are a key component of HEPA filter paper pleating machines. These rollers help evenly distribute tension on the filter paper as it passes through the machine, preventing defects caused by uneven tension. Designed to be highly responsive, these rollers are able to adjust to even the slightest changes in paper thickness or tension, ensuring a smooth and even flow of material. This precision is essential when working with fine HEPA filter paper, which must maintain its integrity throughout the pleating process. Evenly applied pressure helps achieve uniform pleats, which is critical to the filter’s ability to capture airborne particles effectively. Additionally, Dahe makes the rollers from durable, high-quality materials that resist wear and tear, ensuring long-lasting performance and minimal maintenance.

The Impact of Tension Control on Filter Quality and Performance

Maintaining optimal paper tension improves the pleating process and has a direct impact on the quality and performance of the final HEPA filter. Filters with consistent, well-formed pleats have a greater surface area, which enhances their ability to capture particles and increase airflow. When tension is uneven, the pleats deform, reducing the filter’s surface area and efficiency. Dahe’s HEPA filter paper pleating machine consistently applies tension during the pleating process, which ensures even formation and alignment of each pleat. This precision in pleat formation helps improve the quality of the filter, making it perform better over its service life. In addition, optimal tension helps maintain the integrity of the filter paper, preventing damage or breakage during the pleating process.

Achieving Optimal Paper Tension

Dahe’s HEPA filter paper pleating machine provides an advanced and reliable solution for achieving optimal paper tension throughout the pleating process. By integrating an automatic tension control system, precision rollers, and a real-time feedback loop, Dahe’s pleating machine ensures that the filter paper is always stretched to the correct tension, producing uniform pleats, which helps achieve superior filter quality and performance.