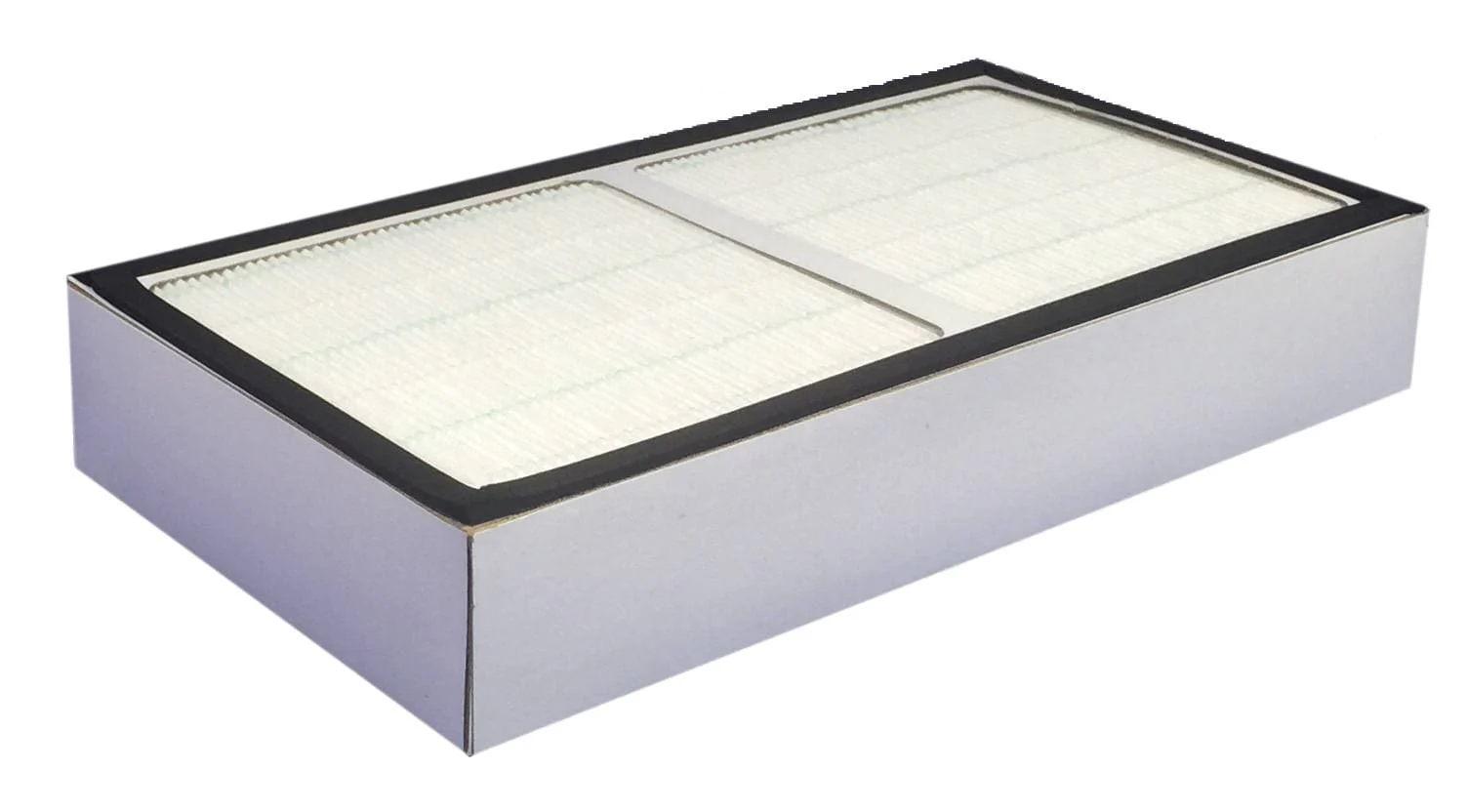

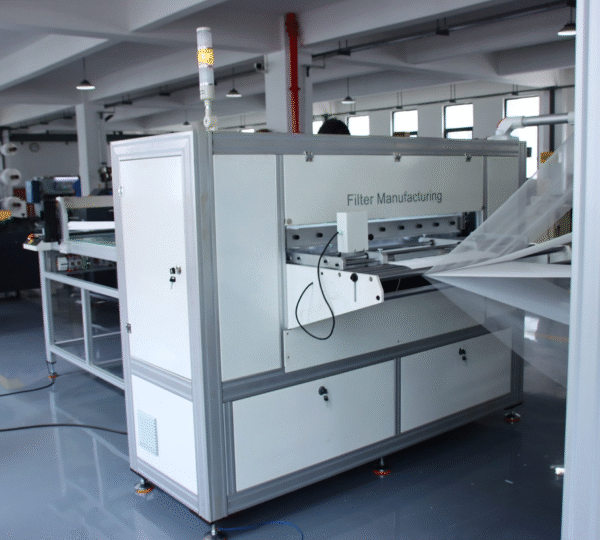

This automatic HEPA assembly production line utilises PLC control to adjust product size and simplify operation. According to incomplete statistics, the output of the fully automatic HEPA line is 80% higher than that of the semi-automatic line. The PLC program was designed to dynamically adjust the flow rate and time according to the filter size, eliminating the need for manual parameter changes. At the same time, the high degree of automation of the line, covering feeding, dispensing, holding pressure, and final assembly, ensures consistent quality, minimal downtime, and maximum output, making this fully automatic HEPA assembly line very suitable for the mass production of square HEPA filters.

Automatic HEPA Assembly Line: Optimising Material Handling and Feeding

Efficient upstream processing directly affects the throughput of the automatic HEPA assembly production line. First, we utilise a synchronous conveyor module equipped with a servo-driven feeder to align the filter media and frame within a tolerance of ±0.5 mm. Additionally, a bulk hopper fitted with a level sensor ensures an uninterrupted supply of pleated media and sealing gaskets. At the same time, I designed a gravity-assisted indexing system to reduce mechanical wear and increase transmission speed to 60 parts/minute.

To reduce manual intervention, photoelectric sensors detect material exhaustion and automatically trigger hopper refilling, while a vacuum conveyor removes waste edges. By eliminating manual feeding errors and bottlenecks, this integrated material handling solution maintains the high productivity necessary for any automated HEPA assembly line and reduces changeover waste.

Precision dispensing and pressure holding on automatic HEPA assembly production lines

On automated HEPA assembly production lines, the key to ensuring product integrity and speed is accurate glue application and pressure regulation. Our dual-nozzle dispenser controls glue dispensing accuracy to within ±2 µL. The pleating system applies adhesive evenly, preventing over-extrusion during filter bonding. At the same time, I calibrated the dispensing pump to start and stop quickly, resulting in a 20% reduction in cycle time. After dispensing, the pneumatic pressure holding cylinder maintains the filter pack pressure at 5 bar for a programmable dwell time controlled by the PLC.

Additionally, an integrated temperature sensor in the glue manifold ensures that the viscosity remains within the optimal range, preventing bond failure. An automatic cleaning cycle flushes the nozzle between batches to avoid clogging. By integrating these precision controls, our fully automated HEPA assembly line combines speed with superior sealing performance, reduced maintenance and increased first-pass yields.

Real-time quality inspection and feedback

The automated HEPA assembly line performs real-time inspections to ensure each unit complies with stringent standards and maintains perfect synchronization. In addition to the vision system, laser triangulation measures the pleat height and seal flatness, immediately detecting defective parts. I configured the PLC to automatically eject any filter with sizing or sealing defects, thereby preventing downstream clogging. Additionally, integrated data logging captures defect rates, allowing for continuous process optimisation through the SPC dashboard on the HMI. Automated trend analysis pinpoints process deviations before they become serious. By embedding automated quality control, the fully automated HEPA assembly production line can maintain yield while meeting stringent cleanroom and filtration performance requirements, raising overall equipment effectiveness above industry benchmarks.

Scalable changeover and maintenance protocols

Fast changeovers and minimal maintenance downtime are critical to maintaining high throughput on the automated HEPA assembly line. Next, quick-release frame rails and modular tool stations enable product size changes in under 10 minutes. However, traditional production lines require hours of adjustments. Additionally, I implemented tool-free clamps and self-aligning couplings for the glue heads and conveyors, which simplified maintenance. Preventive lubrication and automatic self-diagnostic programs run at scheduled intervals, reducing unexpected downtime. With these protocols, the automatic HEPA assembly production line maintains an operational availability of more than 95% and can be easily expanded to accommodate new filter specifications without incurring extensive downtime.

Comprehensive improvement in production output

To achieve high output from HEPA automatic assembly lines, a holistic approach is required, including optimised feeding, precise dispensing, robot calibration, real-time detection, and fast switching mechanisms. Our integrated PLC-driven control strategy achieves a 50% to 80% increase in output while maintaining product quality and consistency. It can meet both mass production targets and strict filtration standards.