A filter assembly demands repeatability, cleanliness, and high throughput. Manual gluing creates variation and slows lines. A Glue Dispensing Machine automates adhesive application, delivering precise beads, consistent volume, and reliable placement. As a result, manufacturers boost yield and cut rework. Below, I explain how glue dispensing systems help filter makers scale with quality and lower cost.

Improved throughput and shorter cycle times

Automated systems apply adhesive far faster than manual work. They measure fluid in milliseconds and run continuously. Consequently, cycle times shrink and takt time improves. For example, a bonded assembly line that added automated dispensing reported a part ready every 11.5 seconds after process optimization. This speed lets plants meet tight delivery schedules for high-volume filter programs.

Consistent deposit volume and placement accuracy

Repeatable bead size and exact placement are essential for filter integrity. Dispensing heads utilize time-pressure, piston, or auger control to precisely dose adhesives. Therefore, each cartridge or frame receives the same amount of glue at the exact location. This uniformity reduces leaks, prevents media misalignment, and cuts rejects. Vendors report markedly lower scrap when lines switch from manual to automated dispensing.

Material savings and waste reduction

Manual glue application often over-applies adhesive. In contrast, automated systems meter only what the design needs. As a result, manufacturers save adhesive and reduce cleanup time. Also, less excess glue prevents downstream defects, such as blocked pleats or impaired airflow. Case studies from integrated dispensing suppliers show material usage drops and cost per part falls after automation.

Better process control and traceability

Modern dispensing cells log setpoints and cycle counts. They record pressure, time, and dispensed volume per part. Thus, quality teams trace every assembly to specific parameters. If an issue arises, engineers analyze logged data to quickly identify the root cause. Moreover, closed-loop systems adjust on the fly when viscosity or temperature drifts. This control improves first-pass yield and supports ISO-style quality systems on the factory floor.

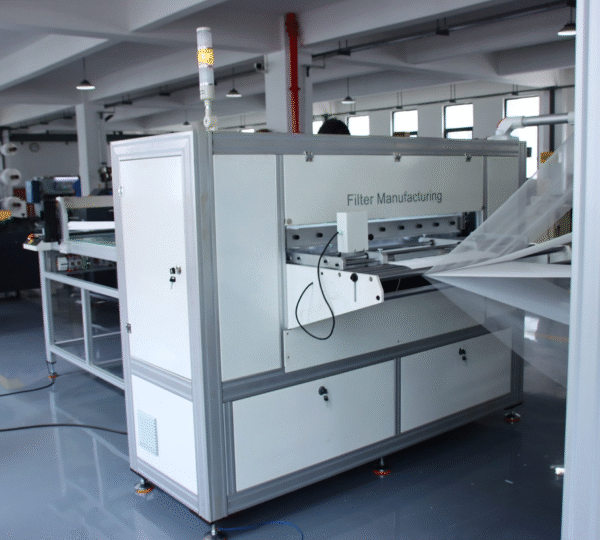

Integration with automated assembly lines

Dispensing stations integrate easily with conveyors, robots, and inspection systems. For example, a robot places a pleated pack while a dispensing head applies a sealing bead. Next, an inline camera checks the continuity of the beads. Therefore, material handling and adhesive application form a seamless sequence. This reduces handoffs, shortens takt, and minimizes human error on the line. Suppliers emphasize turnkey cells for filtration assembly that include handling and cure stations.

Improved worker safety and ergonomics

Automation frees operators from repetitive, tedious tasks. As a result, teams avoid exposure to fumes and reduce the risk of repetitive strain. In addition, closed reservoirs and metered systems reduce spills and airborne particulates. Consequently, facilities experience fewer housekeeping interruptions and lower health and safety risks. These intangible benefits matter when scaling labor-light production while maintaining certifications.

Faster qualification, less variation across runs

When teams use standardized recipes, qualification cycles are shortened. Trials focus on a small matrix of pressure, time, and cure parameters rather than wide human-dependent ranges. Therefore, ramp-up to production becomes predictable. Moreover, repeat orders adhere to the exact specifications without operator-dependent adjustments. This consistency helps meet customer standards for filtration performance and reduces warranty exposure. Industry case studies validate faster qualification and more repeatable runs with automated dispensing.

Practical checklist before installing a Glue Dispensing Machine

First, characterize your adhesive in terms of its viscosity, cure, pot life, and compatibility. Second, pick a dosing technology that matches the adhesive (time-pressure, piston, auger, or gear pump). Third, test with your media and frames to validate bead shape and adhesion. Fourth, integrate inline inspection for bead continuity and volume checks. Fifth, implement SPC logging and preventive maintenance. Finally, train operators and lockdown process recipes to prevent unauthorized changes. Following these steps ensures the glue dispensing investment delivers predictable quality, higher throughput, and lower operating cost.