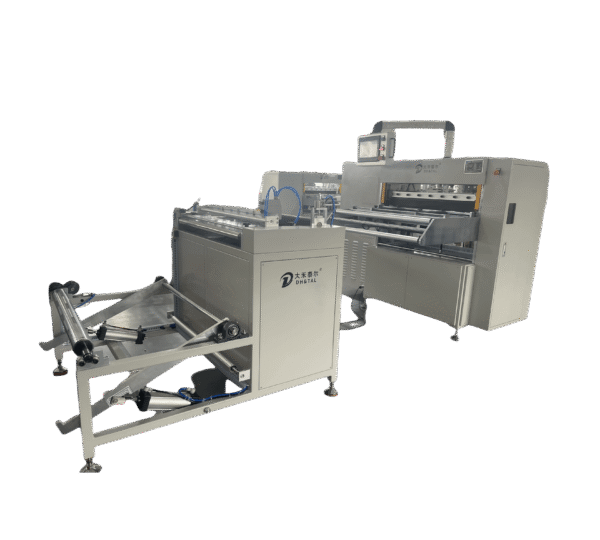

Filter manufacturing has undergone significant evolution with the introduction of automation. Pleating machines have become essential in creating consistent, high-quality pleated media at high throughput. They reduce labor costs, improve precision, and enable manufacturers to meet rising demand. By understanding the mechanics and advantages of these machines, filter producers can optimize operations, enhance product quality, and maintain competitive pricing.

Improved Production Speed

The Pleating machine drastically reduces manual labor. Traditional hand-pleating is slow and inconsistent. Automated machines can pleat dozens of sheets per minute, maintaining uniformity across every filter. This high-speed production ensures manufacturers meet tight delivery schedules. For instance, research by Filtration+Separation indicates that automated pleating can triple throughput compared to manual processes. Faster production directly translates to increased output and lower unit costs, demonstrating the operational advantage of Pleating Machines.

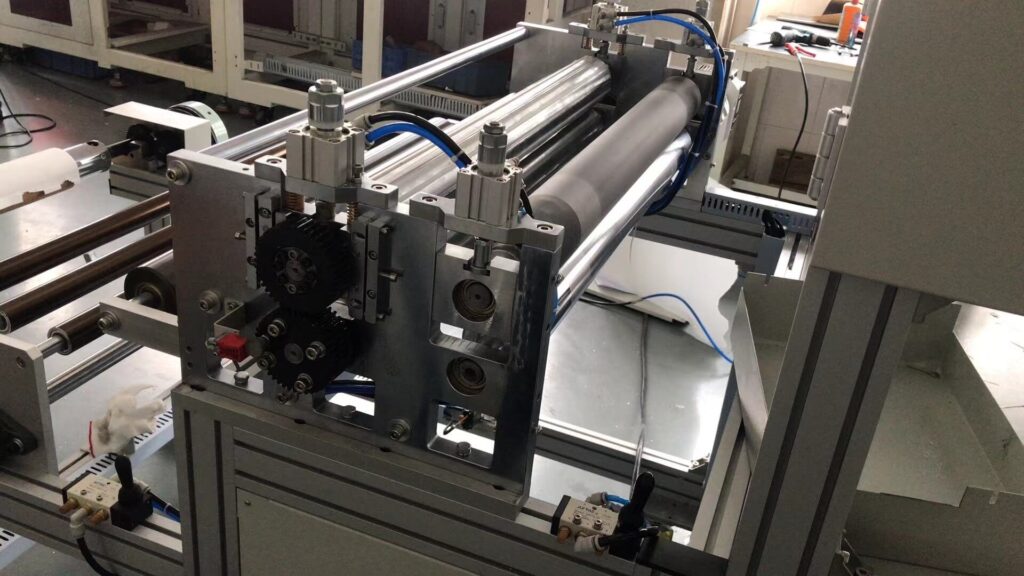

Consistent Pleat Geometry

Maintaining precise pleat spacing, depth, and angle is crucial for filter performance. Manual processes often result in uneven pleats, causing pressure drop variability and reduced filtration efficiency. Pleating Machines enforce tight tolerances automatically, ensuring uniformity. Studies from the Journal of Cleaner Production highlight that consistent pleat geometry improves both efficiency and lifespan of air filters. Reliable pleat geometry guarantees that each filter meets the specified airflow and particle-capture standards.

Material Utilization and Waste Reduction

Optimized pleating minimizes wasted media. Pleating Machines can adjust tension, fold depth, and pitch accurately, reducing scrap. Less wasted media lowers raw material costs and aligns with sustainability initiatives. According to the Environmental Protection Agency (EPA), implementing industrial waste reduction strategies in manufacturing can result in annual cost savings of up to 15%. By improving material utilization, pleating machines not only reduce costs but also support green manufacturing goals.

Flexibility Across Filter Types

Modern pleating machines handle a variety of media types, including cellulose, synthetic fibers, and microglass. They can produce filters for HVAC, automotive, and industrial applications without significant setup changes. Quick tooling adjustments allow manufacturers to switch product lines efficiently. Case studies from Pall Corporation demonstrate that using versatile Pleating Machines reduces downtime when transitioning between filter models. This flexibility is significant for manufacturers serving multiple industries.

Integration with Automated Assembly Lines

Pleating Machines integrate seamlessly into automated production lines. Sensors and robotics can transport pleated media directly to frame assembly or bonding stations. This continuous flow eliminates bottlenecks common in semi-manual setups. Automation reduces labor reliance and enhances throughput. Research by the International Journal of Advanced Manufacturing Technology shows that integrated pleating lines can increase production efficiency by 30-40% compared to standalone machines. Integration ensures higher efficiency and lower operational errors.

Maintenance and Operational Reliability

Reliable Pleating Machines feature low-maintenance components and durable construction. Preventive maintenance schedules keep production running without unexpected downtime. Modern machines include diagnostic tools for detecting tension irregularities or misfeeds before they damage media. According to Maintenance Technology magazine, predictive maintenance on critical machinery can extend service life by up to 20% while maintaining output levels. High reliability ensures consistent product quality and stable production schedules.

Cost Efficiency and Return on Investment

Although the initial investment is significant, the long-term ROI of Pleating Machines is compelling. Reduced labor, lower waste, faster production, and improved quality combine to recoup costs within months for high-volume operations. A case study from Camfil Group reports that integrating automated pleating increased annual output by 200% and cut per-unit costs by 25% (Camfil). Investing in high-quality pleating equipment is economically advantageous for filter manufacturers seeking to scale their operations.

Future Trends and Technological Innovations

Advancements in Pleating Machines include AI-driven tension control, automated quality inspection, and IoT connectivity for real-time monitoring. These innovations allow manufacturers to optimize production dynamically, detect defects immediately, and collect operational data for process improvement. According to Research and Markets, innovative manufacturing technologies in the filtration sector are projected to grow at a 10% annual rate through 2030. By adopting next-generation pleating machines, manufacturers can stay competitive and agile.

Maximizing Efficiency with Pleating Machines

For filter manufacturers, automated Pleating Machines are essential tools for scaling production, ensuring uniformity, reducing waste, and lowering costs. From traditional HVAC filters to specialized industrial applications, these machines enhance efficiency and maintain high-quality standards. Companies that adopt modern pleating technology are better positioned to meet market demands, reduce operational risk, and achieve sustainable growth.