HEPA filters provide clean air in various places, including homes, medical settings, and some cleanroom environments, due to their excellent ability to capture airborne particles. The production process of these filters requires HEPA filter manufacturing machines, which are key equipment for producing HEPA filters. How is it different from other filter production equipment used in various industries? This guide will tell you the specific characteristics of HEPA filter manufacturing machines that are different from other production equipment in terms of precision, materials, and production processes.

What do HEPA filter manufacturing machines do?

HEPA filter manufacturing machines are designed to produce filters that meet specific filtration standards. These machines are designed to handle the unique properties of HEPA filter media, including densely packed fibre materials. Unlike standard manufacturing equipment, HEPA filter manufacturing machines must have more precise control over the production process to ensure the filters meet the strict performance standards required for critical applications.

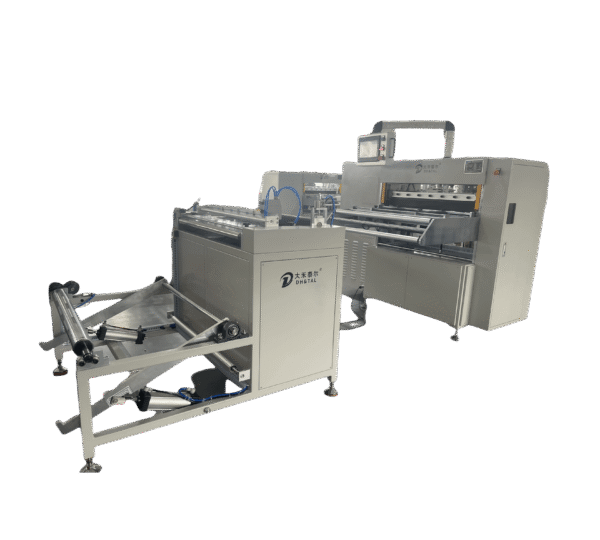

Unlike the equipment used in general filter manufacturing, Dahe’s intelligent HEPA filter manufacturing machine uses a specialized mechanism to handle, fold, and bond the filter media. The process controls temperature, humidity, and air pressure to achieve filtration efficiency and structural integrity. This level of precision is critical to preventing the introduction of contaminants or changes in filter performance, which could compromise the entire filtration process.

Key Components and Features of HEPA Filter Manufacturing Machines

One of the main differences between other production equipment is the specialized components built into the machine. The production of HEPA filters involves multiple stages, each requiring a specific set of equipment to ensure consistent quality. Key components of HEPA filter manufacturing machines include automatic filter media feeders, precise cutting and folding systems, and specialized bonding devices that ensure the filter media is firmly sealed without affecting its filtration performance.

Dahe Intelligent will be equipped with an automated system that allows the system to feed the filter media into the machine with high precision. This ensures that the media is correctly aligned for folding and sealing. Among them, the high precision of the folding machine ensures that the filter media can be folded into pleats of specific sizes while maintaining the structural integrity of the HEPA filter. In contrast, most general filter production equipment is designed for different types of manufacturing. Although these machines may have specialized components, HEPA Filter Manufacturing Machines are better suited for more demanding filters.

More sophisticated manufacturing engineering

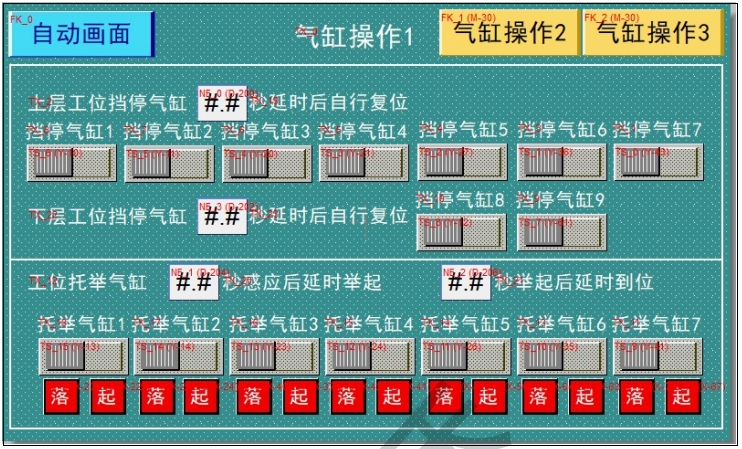

Precision is the hallmark of HEPA filter manufacturing, and the machine provided by Dahe Intelligent controls various factors, including pressure, airflow, and temperature, through a human-machine touch screen to ensure that the filter media does not have any defects during processing that may affect performance. One key factor distinguishing it from other filter production equipment is its ability to make fine adjustments during production. For example, the tension on the filter media can be calibrated to ensure uniform pleat spacing. Similarly, the bonding process can be carefully controlled to avoid introducing contaminants that may reduce the filter’s efficiency. Advanced automation technology minimizes human error and improves production consistency, and high precision can be operated even in high-volume environments.

Better material handling and quality control

HEPA filters require high-performance raw materials, so their handling must be strictly controlled during manufacturing. HEPA filter media is usually made of fiberglass or other synthetic materials, and HEPA filter manufacturing machines are specially designed to carefully handle these materials while maintaining the integrity of the filter structure.

Quality control is another aspect that distinguishes HEPA filter manufacturing machines from other production equipment. These machines have multiple checkpoints throughout production to ensure that each filter meets the required quality standards. They often have sensors that detect defects such as incomplete seals, improper pleating, or incorrect bonding. These quality checks are automated and integrated into the production cycle, allowing real-time monitoring to detect issues at any time.

Higher Automation and Efficiency

Automation is another area where HEPA filter-making machines stand out from other production equipment. Since HEPA filter production has high requirements for precision and cleanliness, automated production is crucial. They have advanced automation systems that precisely control each manufacturing process step. These automation systems help streamline the production process, reduce the need for labour, and minimize human error. Automation also ensures that the machine can run continuously and uninterrupted, thereby improving the efficiency of the production line. Automation can reduce production costs while maintaining product quality in a high-volume manufacturing environment. The machines are programmed to handle delicate materials, maintain a clean environment, and ensure the highest filtration performance.

Better suited for producing HEPA filters

HEPA filter manufacturing machines differ from other filter production equipment in several ways. Their specialized designs, precision engineering, material handling, and environmental considerations make them uniquely suited to produce high-quality filters that meet the stringent performance standards required for critical applications.