Manufacturers in both the automotive and HVAC sectors face constant pressure to deliver high-performance filters. Customers expect clean air, long service life, and affordable costs. At the same time, production plants must stay competitive despite rising labor expenses and stricter standards. Manual processes often fall short, especially when speed and accuracy are critical. This is where folding equipment becomes essential. By integrating advanced folding equipment into filter pleating lines, producers can automate workflows, improve consistency, and maintain high-quality output while boosting overall efficiency.

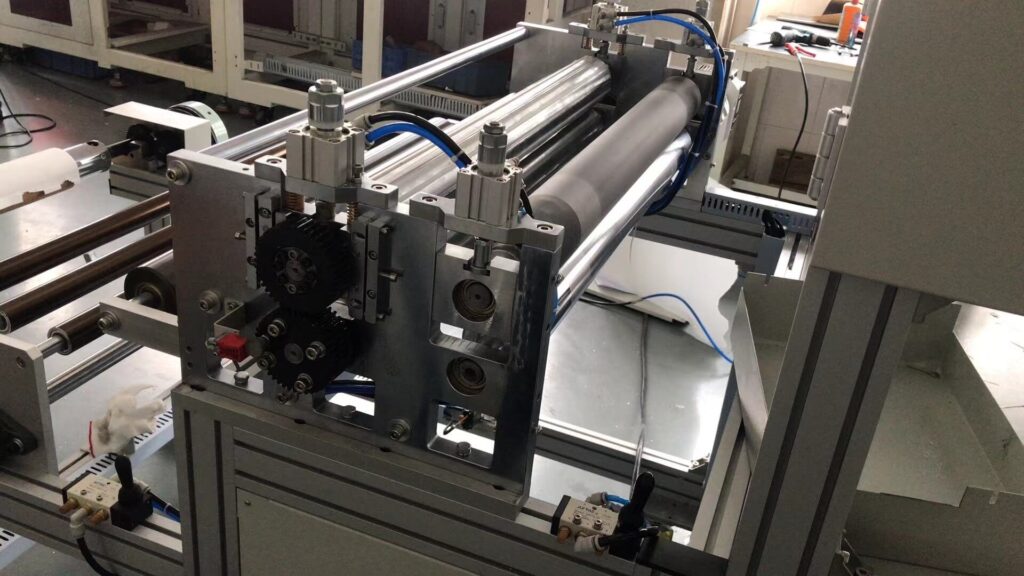

Precision in filter pleating

Folding machines create uniform pleats in filter media. Each pleat is consistent in height, depth, and spacing, which directly impacts performance. In vehicles, precise pleating ensures cabin air filters and engine filters capture harmful particles without blocking airflow. In HVAC systems, accuracy improves airflow efficiency, reduces system strain, and prevents early equipment failure. Manual folding often produces uneven results, but automated folding equipment guarantees repeatability. This precision not only protects end users but also reduces rework and waste in production lines.

Higher production speed

Speed is a clear advantage of folding machines. Manual pleating can take minutes for a single filter, while automated machines handle hundreds per hour. Automotive suppliers need this speed as cabin air filters, oil filters, and intake filters are replaced more often in modern cars. HVAC manufacturers face similar pressure as building owners demand large volumes of filters to maintain indoor air quality. Faster cycle times mean manufacturers can keep up with seasonal demand spikes, respond to urgent orders, and reduce lead times. Folding equipment makes it possible to combine scale with reliability.

Cost savings through automation

Labour costs are increasing, and retaining skilled operators is difficult. By automating pleating, manufacturers reduce dependency on manual work and lower per-unit expenses. Automation also limits material waste by minimising errors, since misaligned pleats or uneven folds can render filters unusable. Savings accumulate over time, especially in high-volume operations. Automotive suppliers benefit from stable, predictable costs, while HVAC manufacturers can price their products competitively. Folding equipment not only cuts direct labour but also reduces hidden costs associated with quality issues and downtime.

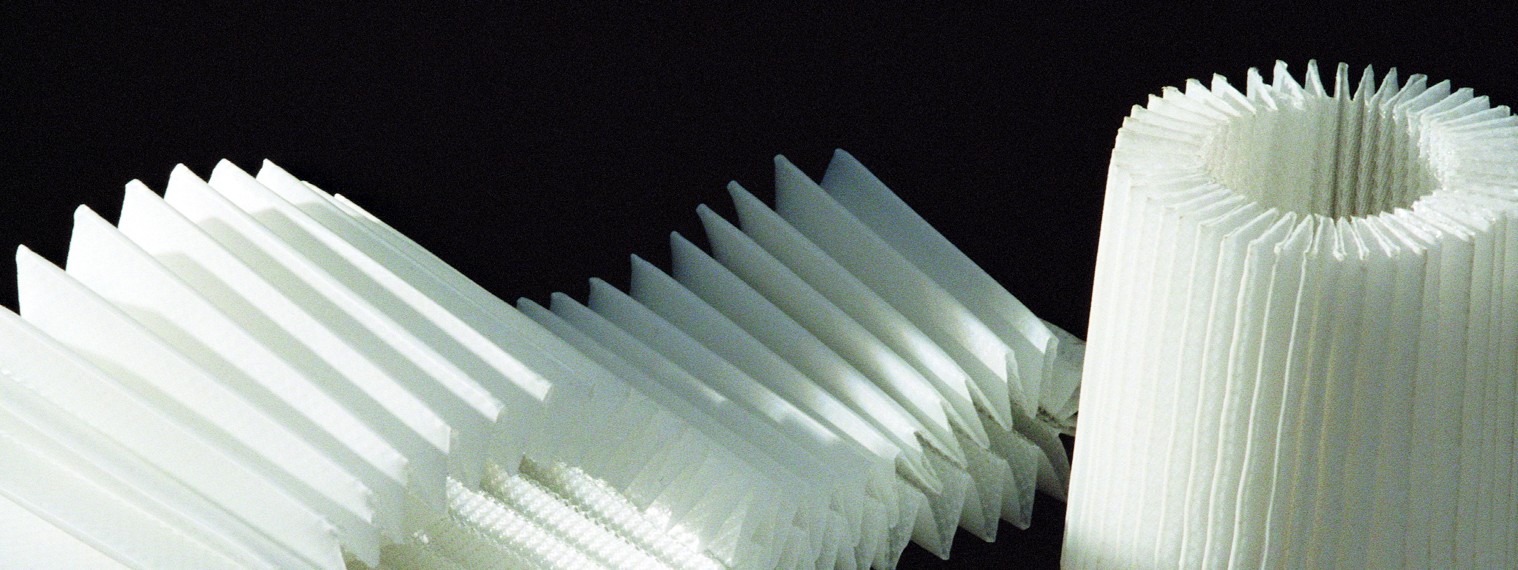

Adaptability for different filter types

Modern folding machines are designed for flexibility. They can process filter media of different thicknesses, coatings, and fibre types. Automotive filters must withstand heat, pressure changes, and exposure to fuel vapours, while HVAC filters must remain effective in humid conditions and over long service intervals. Quick changeover functions on folding machines allow manufacturers to switch production lines with minimal delays. This adaptability supports diverse product ranges and short production runs without compromising efficiency. Folding equipment, therefore, helps producers serve more customers with less disruption.

Improved energy efficiency in production

Energy consumption is now a critical factor in manufacturing. Advanced folding equipment often features energy-saving motors, variable frequency drives, and optimised controls. This reduces power usage per unit produced. Automotive and HVAC industries both operate in markets where sustainability matters to customers and regulators. Energy-efficient machines not only lower utility costs but also strengthen compliance with environmental standards. Manufacturers can market their filters as being made with sustainable practices, adding value in competitive markets. Folding equipment thus contributes to both financial and ecological goals.

Quality assurance and consistency

Product reliability is non-negotiable. Inconsistent pleating can cause filters to fail prematurely, leading to customer dissatisfaction and warranty claims. Automated folding ensures uniform pleat structures across thousands of units. Automotive engines rely on stable air intake, and HVAC systems depend on predictable airflow resistance. Folding machines equipped with sensors and monitoring tools further improve quality control by detecting irregularities in real time. Consistency achieved through folding equipment builds trust with clients, reduces risk, and strengthens brand reputation.

Supporting future growth

Demand for filters will continue to rise as vehicle numbers grow and air quality regulations tighten. Manufacturers must plan for expansion without compromising quality or cost control. Folding machines can integrate into fully automated lines, combining pleating with cutting, gluing, and frame assembly. This scalability allows businesses to increase capacity quickly when needed. For automotive suppliers, it means meeting stricter emission and efficiency standards. For HVAC producers, it means responding to demand for higher-grade filters in commercial buildings and homes. Folding equipment ensures growth can be achieved sustainably and efficiently.

Why folding equipment matters in production

Reliability and scalability are essential in filter production today. Folding machines provide precision in pleating, higher production speed, reduced costs, and energy savings. They adapt to diverse filter designs, ensure consistent quality, and support long-term growth strategies. Automotive and HVAC industries both benefit from these advantages, especially as customer expectations and environmental demands intensify. By investing in modern folding equipment, manufacturers secure not just better filters but also stronger competitiveness in global markets.