Modern filtration systems require precision, durability, and customization. From automotive filters to industrial HVAC solutions, manufacturers face growing demands for efficient and tailored products. To meet these needs, advanced machinery plays a critical role in balancing quality and cost. One of the most essential tools is Filter Media Folding Equipment, which ensures consistent quality, flexible production, and adaptability for various industries.

Ensuring Consistent Fold Quality

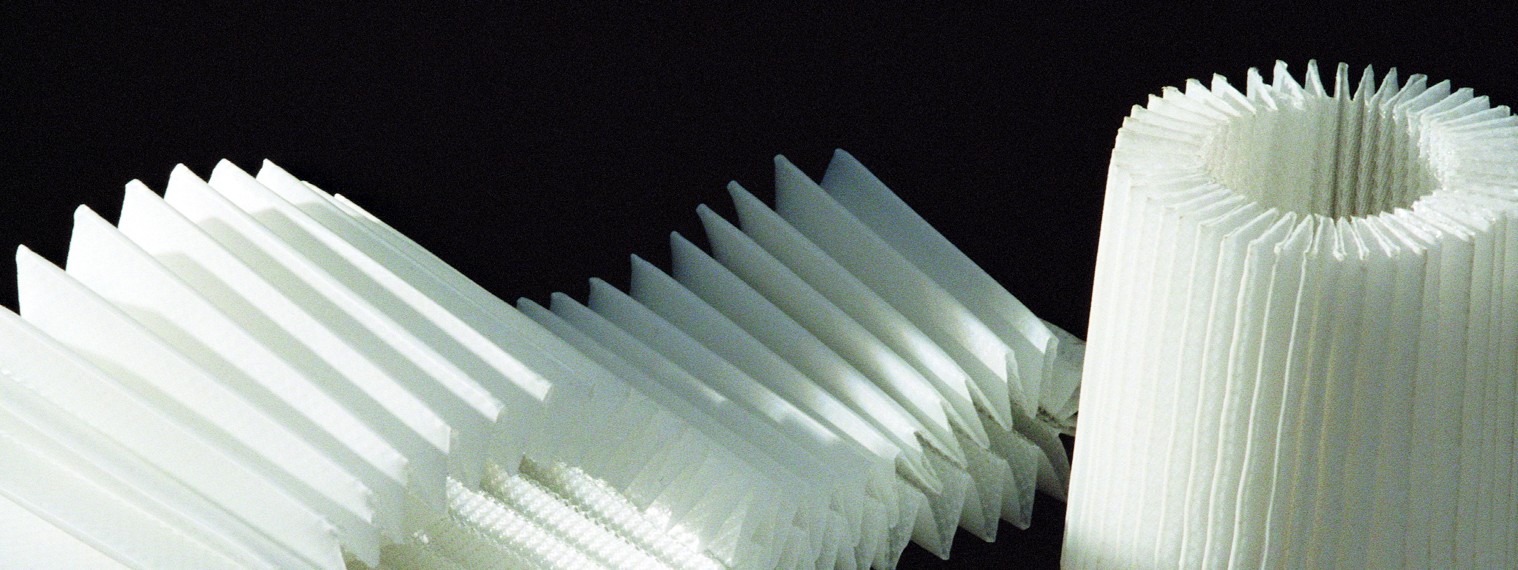

Uniform folds are essential for reliable filter performance and long service life. Poor folding can create gaps or uneven density, reducing filtration efficiency and risking system failure. With Filter Media Folding Equipment, manufacturers maintain consistent spacing and alignment throughout the production process. This accuracy directly improves airflow management and contaminant capture, enhancing overall performance. Moreover, precise folding reduces material waste, saves costs, and supports sustainability initiatives across filter manufacturing operations.

Supporting Customized Designs

The demand for custom filters continues to rise in industries like healthcare, automotive, and food processing facilities. Each sector requires unique shapes, fold depths, and specific configurations. Filter Media Folding Equipment allows manufacturers to adapt quickly to these requirements without costly redesigns. Adjustable settings enable operators to fine-tune folds based on customer specifications and performance criteria. This flexibility ensures that even complex designs meet high standards, delivering reliable products while maintaining strong production efficiency.

Boosting Production Efficiency

High-volume production demands speed without sacrificing quality or consistency. Traditional manual folding methods cannot keep up with today’s demanding market requirements. Automated Filter Media Folding Equipment streamlines production by delivering consistent results at higher speeds with reduced labor needs. Furthermore, built-in monitoring systems reduce costly errors and minimize downtime during long production runs. As a result, manufacturers achieve faster turnaround times while maintaining strict quality standards and improving profitability in filtration product lines.

Enhancing Filter Durability

Filter lifespan is directly tied to how the media is folded and supported during assembly. Uneven folds may lead to stress points, causing early wear or failure under heavy use. With Filter Media Folding Equipment, filters maintain stable structures that withstand long operating cycles without deformation. Enhanced durability means fewer replacements, lower maintenance costs, and greater customer satisfaction across industries. Automotive, heavy machinery, and HVAC manufacturers especially benefit from this consistent reliability and long-lasting performance.

Integration with Modern Manufacturing Systems

Smart factories and Industry 4.0 demand equipment that integrates seamlessly with advanced production lines. Modern Filter Media Folding Equipment supports data collection, real-time monitoring, and digital process adjustments. This integration ensures consistent traceability, compliance, and quality control in every production run. In addition, connectivity allows operators to optimize machine performance and predict required maintenance before breakdowns occur. As a result, manufacturers stay competitive in a global market that prioritizes efficiency, accuracy, and production transparency.

Applications Across Diverse Industries

The versatility of Filter Pleating Equipment extends across many fields and continues to expand. In medical devices, it ensures sterile and reliable air or liquid filtration systems. In the food industry, it maintains hygiene standards through effective contaminant removal and strict safety compliance. For automotive and aerospace, it supports high-performance filters capable of withstanding extreme operating conditions and extended use. This broad application demonstrates how folding technology drives innovation and efficiency across different industrial sectors today.

Final Thoughts on Filter Media Folding Equipment

Customized filtration products are essential in today’s competitive industries, and their performance depends heavily on precise folding processes. By using the Filter Media Pleating Machine, manufacturers achieve consistent quality, design flexibility, and enhanced durability across product lines. Additionally, its integration with smart systems ensures efficiency and competitiveness over the long term. Investing in advanced folding machinery is not just about faster production—it is about meeting customer demands reliably. Ultimately, no modern filtration business can thrive without leveraging Filter Media Folding Equipment.