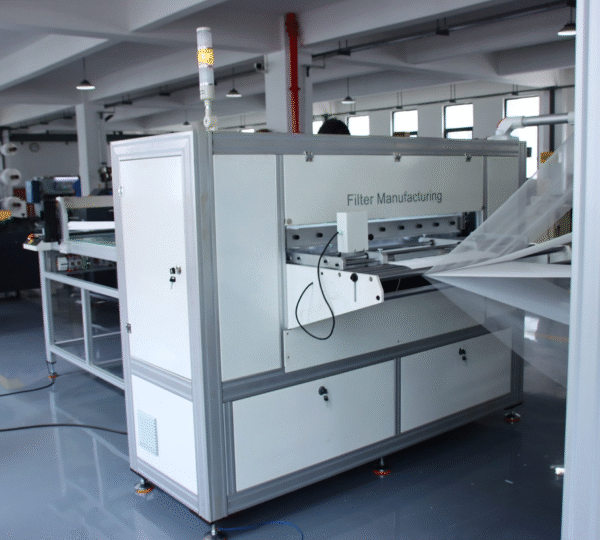

In air filter manufacturing, manual pleating of filter media slows production and leads to inconsistencies. Filter media folding equipment automates this critical step, significantly improving efficiency. By precisely pleating the filter media, the equipment reduces errors and accelerates production. Automation means fewer defects and less downtime. Beyond speed, uniform pleat formation enhances filter performance. Filters with precise pleats have better airflow and capture efficiency. Therefore, reliable pleating equipment is crucial. By minimizing variability, filter media pleating equipment helps maintain high standards and ensure regulatory compliance.

Minimizing Waste and Maximizing Yield with Precision

Wasted filter media means lost profits. Manual folding creates uneven pleats and scrap material, wasting expensive filter media. Filter Media Folding Equipment uses precise controls to fold media consistently, drastically reducing waste. This precision saves money by maximizing the usable material in each production run.

Moreover, less waste leads to fewer interruptions. Production runs become more predictable, lowering overall operational risk. Higher yields also improve sustainability by cutting raw material consumption. Companies that adopt Filter Media Folding Equipment enjoy stronger margins and a greener footprint, both of which are increasingly important in today’s market.

Achieving High Speed Without Sacrificing Quality

Many manufacturers struggle to strike a balance between production speed and product quality. The filter folding machine solves this by maintaining high-speed folding without sacrificing pleat accuracy. The machines utilize advanced mechanisms to fold media at a steady pace, ensuring uniform pleat dimensions.

Consistent pleats prevent problems downstream, such as filter leaks or failure during testing. The equipment’s design focuses on stability and control, allowing manufacturers to run continuous production without frequent stoppages. This balance of speed and quality makes Filter Media Folding Equipment indispensable for efficient production of air filters.

Enhancing Workplace Safety and Cutting Labor Costs

Folding filter media manually is a repetitive task that can physically strain workers. Filter pleating equipment automates this task, reducing manual handling. This reduces the risk of repetitive strain injuries and workplace accidents.

At the same time, the need for labor on folding lines decreases. Operators shift focus to monitoring and quality assurance rather than physically demanding tasks. The result is a safer work environment and more efficient use of staff. These benefits contribute to lower labor costs and better employee satisfaction.

Flexible Operation for Diverse Filter Products

Air filter manufacturers produce a wide range of filter sizes and types. Filter material folding machine features adjustable settings to accommodate various media thicknesses and pleat depths. This flexibility allows manufacturers to switch between product lines quickly.

Fast changeovers enhance production agility, enabling companies to respond promptly to customer needs or market trends. The ability to handle multiple filter types with one machine reduces capital expenditure and simplifies maintenance. Such adaptability enhances the overall value of investing in a Filter media pleating machine.

Seamless Integration into Automated Production Lines

Modern filter manufacturing often relies on automation throughout the entire process. Filter Media Folding Equipment integrates seamlessly with upstream and downstream systems, including media feeding and filter assembly lines.

Integrated systems enhance workflow efficiency and minimize bottlenecks, thereby improving overall productivity. Real-time monitoring detects issues early, preventing quality problems or downtime. The connected approach also allows for data collection and process optimization over time. This holistic production strategy ensures the best use of Filter Media Folding Equipment and maximizes output.

Meeting Global Quality and Compliance Standards

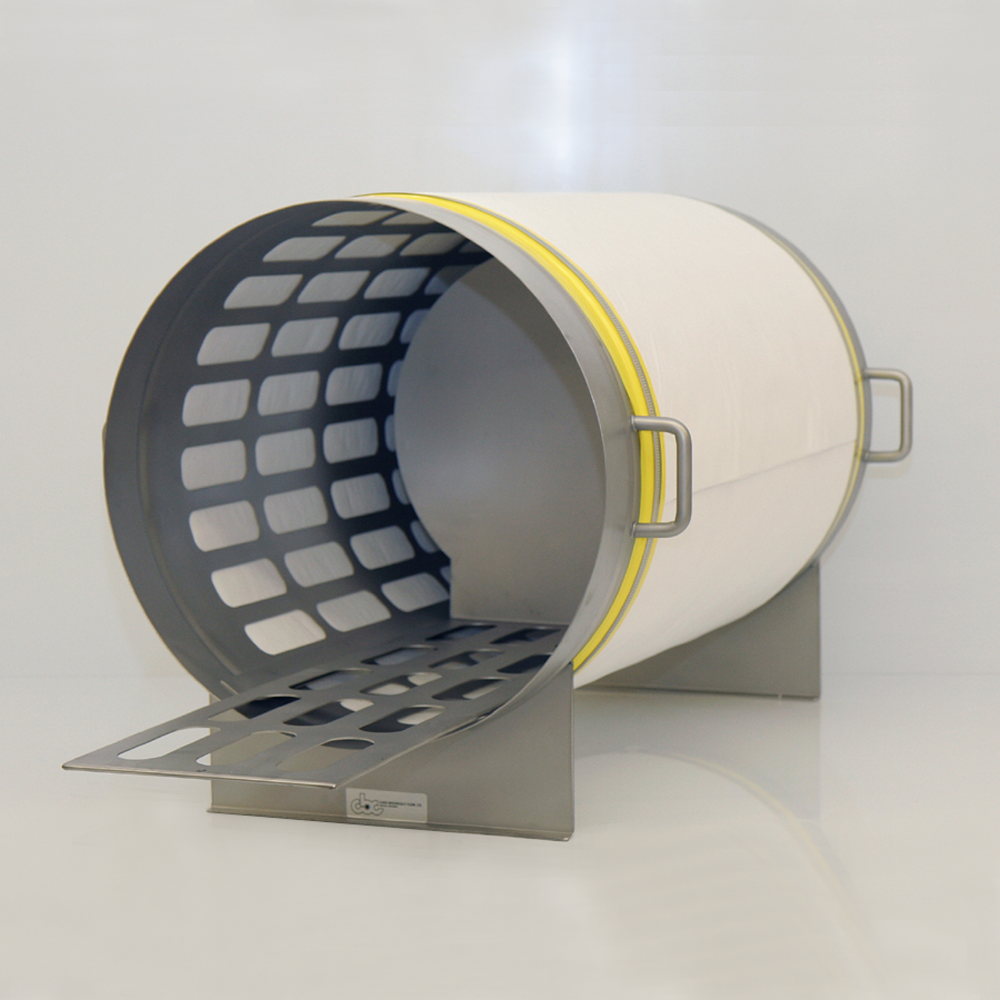

Uniform folding is essential for meeting international air filter standards. Filter Media Folding Equipment produces precise, repeatable pleats that comply with stringent quality requirements.

Meeting these standards allows manufacturers to compete globally with confidence. Avoiding defects reduces the cost of costly recalls or rework. Additionally, maintaining quality boosts brand reputation and customer trust. Companies relying on advanced folding equipment position themselves as industry leaders on the world stage.

Driving Growth with Filter Media Folding Equipment

Filter Media Folding Equipment delivers significant efficiency improvements in the manufacturing of air filters. It accelerates production, reduces waste, maintains quality, enhances safety, and offers operational flexibility. These advantages translate into better profitability and sustainability.