Injection-based methods have changed the way many filters are made. They let manufacturers combine precision, speed, and repeatability. Today, filter injection covers overmolding, encapsulation of media, and advanced melt-infiltration processes. As a result, manufacturers can scale reliably while maintaining consistent product performance. Below, I explain how the technology works, why it improves quality, and what practical steps operations teams should take to implement it.

What filter injection actually is

Filter injection generally refers to the use of injection molding or related melt processes to form filter components or encapsulate filter media. For example, manufacturers inject plastic around wire mesh, nonwovens, or support cores. This creates a bonded assembly with precise dimensions. Overmolding also seals edges and protects media from handling damage. Therefore, injection turns hand-assembled parts into standardized, production-ready items.

How repeatability drives consistent quality

Injection machines run the same cycle every time. They measure melt, pressure, and cooling with tight tolerances. Consequently, parts come out with minimal variations between cycles. This repeatability reduces defects, ensures dimensional control, and maintains filter performance within specifications. Moreover, process controls such as SPC and automated feedback further tighten variation. In short, stable injection parameters equal predictable filtration results.

Design-for-manufacturing reduces assembly errors

When engineers design parts for injection, they also optimize joints, seals, and media positioning. They add features like molded locating bosses and integrated gaskets. As a result, assembly steps are either eliminated or reduced in length. For example, a molded frame that captures the media eliminates the need for manual gluing and alignment. Therefore, the risk of misassembly drops. This improves first-pass yield and reduces rework costs across large runs.

Material control and contamination prevention

Injection environments let manufacturers control materials precisely. They select resins based on their chemical compatibility, durability, and heat resistance. Moreover, clean molding cells and closed tooling reduce particulate ingress. For critical filters, such as medical-grade or HEPA housings, this significantly reduces the risk of contamination. Additionally, overmolding protects sensitive media from physical damage and moisture during downstream processing. Thus, injection supports higher cleanliness standards in mass production.

Advanced techniques: melt infiltration and hybrid methods

Beyond simple overmolding, advanced “melt infiltration” and hybrid processes improve structure and performance. Melt infiltration can densify or bond porous preforms with a controllable matrix. This yields rigid parts with integrated porosity in targeted areas. Such approaches allow designers to tune pressure drop and strength simultaneously within the same cycle. Fraunhofer and other laboratories have demonstrated these methods for complex porous components, showing clear benefits in terms of consistency and mechanical integrity.

Automation and inline quality assurance

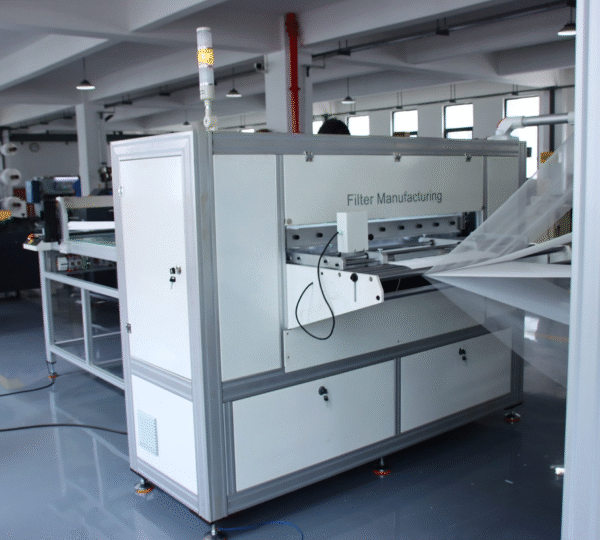

Modern injection lines pair with automation for stacking, sealing, and testing. For example, dedicated cabin-filter lines combine pleating, injection overmolding, trimming, and automatic inspection. Inline sensors measure flow resistance and check dimensions immediately after molding. Consequently, defective parts are never allowed to proceed further down the line. This closed-loop approach reduces scrap and ensures only parts that meet specs move to packaging. Case studies demonstrate that integrated lines minimize cycle time and enhance throughput.

Economic and sustainability impacts of filter injection

Injection reduces unit labor and rework costs. It also lowers scrap through better yields and precise material usage. For large-volume runs, the tooling cost pays back quickly. Furthermore, manufacturers can select recyclable resins or designs that require less material. As a result, production becomes both more cost-effective and environmentally friendly over time. Companies that switch to injection-based assemblies often report lower total cost of ownership and improved environmental metrics.

Practical checklist to implement Filter Injection

First, validate the media-to-resin compatibility with small-scale trials. Second, engage tooling designers early to capture media with minimal stress. Third, instrument the press for SPC and install inline leak/flow checks. Fourth, pilot a fully automated cell that includes handling and inspection. Fifth, review material sustainability and recycling options. Finally, document change control and train the floor team on contamination control. Following these steps ensures a smooth transition to industrialized Filter Injections with repeatable, high-quality output.