In the HEPA production line, the HEPA assembly machine presses the filter material into a rigid frame with uniform pressure, ensuring that each filter meets high-performance standards. The HEPA assembly line provided by Dahe Intelligent is equipped with a three-axis dispenser, a pressure maintenance device, and an automatic unloading system, enabling seamless and precise assembly work. They can move the dispensed product left and right to maintain pressure and perform HEPA dispensing and pressing assembly work perfectly. One person can operate one device, which is cost-effective, simple to use, and practical.

HEPA assembly machine uses three-axis dispensing technology to achieve precise adhesive application

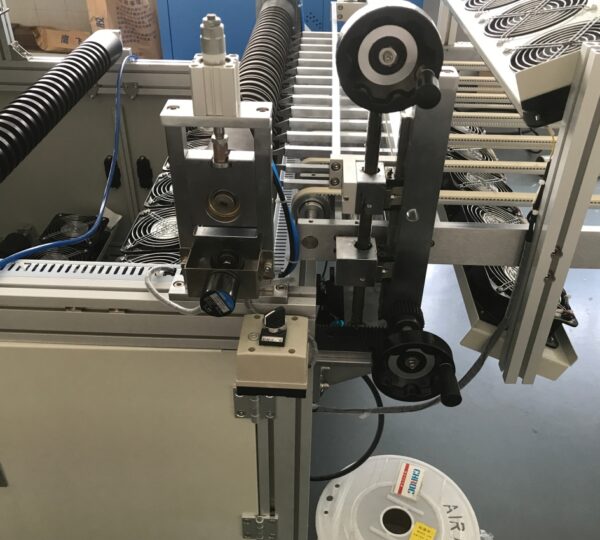

The core of the Dahe Intelligent HEPA assembly machine lies in its three-axis dispensing head, which ensures the precise positioning of the adhesive along the filter frame. The dispensing machine moves linearly along the X, Y, and Z axes and can adapt to various square HEPA filters. Among them, we can adjust the dispensing speed and flow rate in real-time through the control panel to compensate for slight differences in frame size. For example, suppose the machine’s vision system detects a 0.5 mm deviation from the edge of the frame. In that case, the dispensing head will automatically adjust the path to maintain a perfect joint effect. In addition, this dynamic regulation prevents the over-application of adhesive, avoiding cold flow defects while also eliminating gaps that affect filter efficiency. This allows the HEPA assembler to ensure that each filter receives the exact amount of adhesive needed for a strong bond.

Pressure maintenance device for uniform frame sealing

After dispensing, maintaining consistent pressure during the curing process allows for a perfect press fit. On the HEPA assembly line, pressure maintenance devices apply a controlled force to the filter frame from both sides. These devices clamp the frame on a precision fixture, ensuring that the adhesive layer is evenly bonded around the entire perimeter. In practice, sensors embedded in the pressure maintenance devices continuously monitor the applied pressure and adjust in real time to maintain the target pressure, which is typically between 20 and 50 N/cm², depending on the filter size. If the pressure deviates by more than 2% due to slight warping of the frame, the system compensates by adjusting the cylinder extension. As a result, the HEPA assembler eliminates dead zones where the adhesive may not cure properly, ensuring that every millimeter of the filter edge is evenly sealed.

HEPA assembly machines feature automatic unloading to simplify production processes

Automatic unloading devices on HEPA assembly machines can remove finished filter elements from the press area without human intervention and transport them to downstream stations for curing or final inspection. This hands-free handling method minimizes cycle time and reduces labor costs.

These unloading devices typically utilize electric grippers or vacuum suction heads to gently lift the filter element, thereby avoiding disturbance to the adhesive seal. These grippers align precisely with the filter frame’s cutout area, enabling operators to handle delicate filter elements safely without excessive force. Additionally, conveyor integration synchronized with the machine cycle timer ensures that each filter element moves to the next station immediately after pressing, thereby avoiding downtime and maintaining a steady production rhythm. By automating the unloading process, HEPA assembly lines can maintain high output rates while maintaining assembly quality.

Synchronized left and right movement to maintain pressure balance

The advantage of Dahe’s intelligent HEPA assembly machine is its ability to move products laterally (left and right) while maintaining constant pressure. This bidirectional motion enables the machine to access multiple clamping and dispensing stations within a single work cell, effectively doubling throughput without adding additional presses. As the filter frame moves, the pressure maintenance device adjusts in real-time to ensure that the pressure at each station remains at the target value.

When the conveyor or transfer device initiates the lateral movement, the motion controller coordinates with the servo drive that controls the pressure actuator. When the frame moves to station B for additional bonding reinforcement, the left pressure cylinder retracts slightly while the right pressure cylinder extends to maintain a constant net pressure. As a result, the HEPA assembly machine can perform multi-step processes in rapid succession without interrupting the pressure. This synchronized motion improves efficiency and ensures that each filter undergoes the same assembly procedure.

Quality Assurance for Pressed Assembly

To ensure a perfect press-fit assembly, a strong quality assurance system must be integrated directly into the HEPA assembly line. A camera mounted above the press area captures high-resolution images of each filter edge, ensuring that the glue bead is continuous and free of gaps. At the same time, the pressure sensor data records the actual force curve throughout the press cycle, enabling traceability to individual units.

The HEPA assembly machine simultaneously compares live data to preset thresholds and enables this feature to eject any filter that exceeds acceptable deviations immediately. Operators receive real-time alerts on the HMI screen and can view trend graphs to identify deviations in actuator performance or inconsistent feeds. By embedding these quality checks into the HEPA assembly machine, manufacturers can reduce rework by identifying potential defects before the product enters downstream stations.

Achieving Perfect Assembly

The HEPA assembly machine ensures perfect press-fitting of HEPA filters through three-axis precision dispensing, pressure-holding actuators, automatic unloading, synchronized bidirectional motion, and integrated quality assurance. By leveraging real-time feedback from sensors and cameras, the HEPA assembly line ensures consistent adhesive application, uniform clamping force, and controlled operation, thereby guaranteeing that all HEPA filters produced have a perfect seal, which passes leak rate testing and performance evaluation.