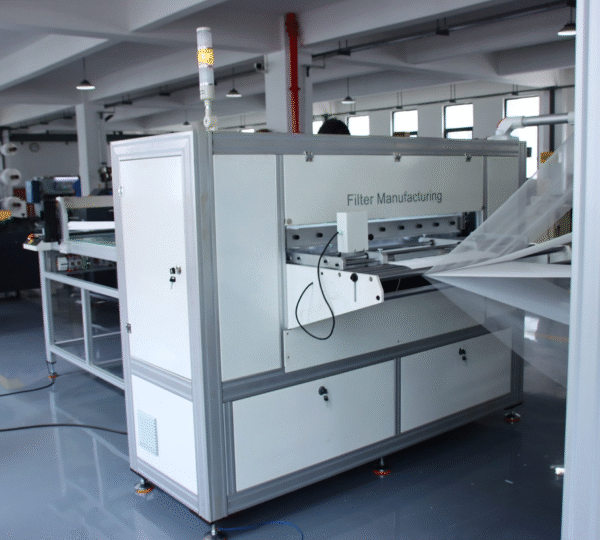

In producing air filters, the filter element must be firmly bonded to other components to maintain its integrity and performance in various applications. Traditionally, the glue injection process is manual, leading to inconsistent applications, more prolonged production cycles, and higher labor costs. The fully automatic glue injection production line has changed the way filter elements are produced. By automating the glue injection process, manufacturers can achieve higher precision, higher yields, and reduced waste. Therefore, we will share with you how the fully automatic glue injection production line provided by Dahe Intelligence can improve the filter element glue injection process, thereby improving efficiency, reducing operating costs, and improving product quality.

A fully automatic glue injection production line improves glue coating accuracy

One of the most significant advantages of the fully automatic glue injection production line is its ability to provide precise and consistent glue injection during the filter element assembly process. In traditional manual glue injection systems, glue volume variations and application speed can lead to uneven bonding, affecting the quality and performance of the filter element. This inconsistency also leads to material waste.

In an automated production line, the glue injection process is controlled by a computer system that accurately measures and injects the required glue. The computerized system ensures the even distribution of glue on the filter element, minimizing the risk of excessive or insufficient glue. This results in a higher-quality product with a stronger bond, ensuring the filter performs optimally in the intended application. In addition, fully automated glue injection lines reduce human error, ensuring that each filter element meets the required specifications, ultimately improving product quality and consistency.

Fully automated glue injection lines improve production efficiency

Traditional glue injection methods usually require manual labor, slowing production and increasing labor costs. Workers must apply glue to each filter element individually, a time-consuming process prone to delays. Fully automated glue injection lines streamline the entire production line. The system runs continuously, injecting glue into the filter element much faster than manual methods. The increase in speed means that the machine produces more filters in a shorter time, thereby improving overall productivity. With automated glue injection, manufacturers can shorten production cycles, increase output, and meet higher demand. At the same time, operators can program it to run 24/7 with little intervention, achieving 24/7 production to reduce downtime and further improve efficiency.

Reduce costs through automation

One of the main concerns of air filter manufacturers is to control operating costs. Labor, raw materials, and equipment maintenance increase production expenses. Fully automated glue injection production lines can minimize glue waste by reducing the need for labor. With automated glue injection systems, manufacturers can reduce labor costs by eliminating the need for multiple workers to apply glue to each filter element manually. In addition, the automated system ensures the precision of applying the exact amount of glue to each filter element, avoiding overapplication and thus reducing glue waste. At the same time, it also reduces the possibility of errors that lead to product defects. Over time, the cost savings brought by automation will be considerable, allowing manufacturers to achieve more goals with fewer resources and improve profitability.

Improve product quality and consistency

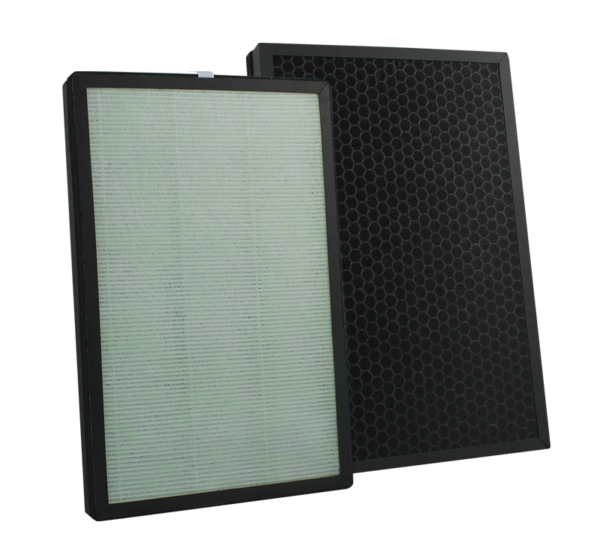

Small changes in product specifications can also affect the filter’s performance. Engineers design fully automated glue injection production lines to ensure that each filter element is produced with the same high precision, thereby improving overall product quality. The automated system always applies glue to the filter element at the same speed, pressure, and volume, reducing the differences in the manual process. This consistency ensures that each filter element meets the required specifications for bonding strength, bonding quality, and overall integrity. The result is a more reliable end product that performs as expected, whether used for automotive air filters, industrial purifiers, or HVAC systems. Manufacturers can reduce defects and scrap rates by standardizing the glue injection process. This can reduce returns and customer complaints.

Production flexibility and strong adaptability

The fully automatic glue injection production line is efficient, economical, highly flexible, and adaptable to various production needs. Air filter manufacturers often need to produce different types and specifications of filter elements according to customer requirements or product design. Operators can easily reprogram them to adapt to the kind of glue. This adaptability lets manufacturers quickly switch between production processes without extended downtime or re-equipment. For example, a manufacturer may need to switch from producing automotive air conditioning filters to producing industrial air filters. The fully automatic glue injection production line can seamlessly handle these changes, allowing manufacturers to meet different customer needs while maintaining high efficiency.

Bring more efficient and flexible filter element production

The fully automatic glue injection production line significantly advances the air filter production process, improving production accuracy and efficiency, reducing costs, and improving product quality. As the demand for high-quality and high-reliability filter elements in all walks of life grows, the fully automatic glue injection production line will play an increasingly important role in meeting these needs.