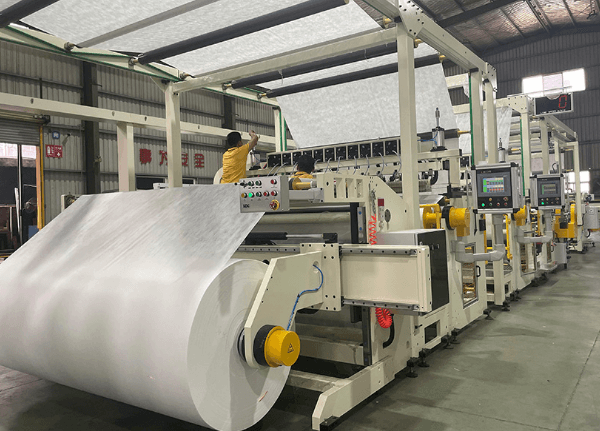

The filtration process’s efficiency and accuracy depend on the filter’s design and manufacture, and one key component to improving filtration efficiency is pleating the filter media. Paper pleating machines enhance filter performance, especially in applications requiring high filtration accuracy and capacity. In this guide, we will explore how Dahe Intelligent’s paper pleating machines can help improve the filtration process in industrial applications. Dahe Intelligent has developed a paper pleating machine that optimizes filter production, ensuring better performance, durability, and efficiency.

Paper Pleating Machine: Improve Filtration Efficiency with Advanced Servo Motor Technology

One of the main factors affecting the quality of pleated filter paper is the pleating machine’s operating accuracy. Dahe Intelligent’s paper pleating machine uses advanced servo motors to drive the rack lifting mechanism, which can ensure stable machine operation and reduce vibration and inconsistency during the pleating process. By better controlling the pleating cycle, the servo motor drive system allows for more consistent and precise pleating, critical to producing reliable filter papers under different industrial conditions. The servo motor can fine-tune the lifting and pleating action of the machine, allowing it to produce filters with more uniform pleat height and spacing. This uniformity directly affects the surface area of the filter media and its ability to capture contaminants. With Dahe’s Intelligent paper pleating machines, the industry can achieve higher filtration efficiency and longer filter life, reducing the need for frequent replacement.

Paper pleating machine with adjustable pleating height for customized filtration performance

A significant advantage of the Dahe paper pleating machine is the ability to adjust the pleat height of the filter media. The machine has a stepper motor on the table that drives the linear guide rail up and down. This setup allows for precise control of the pleat height and can also be adjusted to the specific requirements of the filtration application. By varying the pleat height, the pleating machine can change the density and surface area of the pleated filter media, making it suitable for various filtration tasks. Adjustable pleat height is critical in applications that require different filtration stages or different levels of filtration accuracy. In addition, the customized filter structure therein ensures that the right filter is provided for various tasks, from coarse filtration to fine filtration. Dahe Intelligent’s paper pleating machine offers this flexibility, making it a valuable tool for manufacturers in multiple industries.

Reduce material waste through efficient design

Material waste directly impacts operating costs and the overall sustainability of production, and Dahe’s Intelligent paper pleating machines are designed to minimize material waste during the pleating process. They feature press bars in the pleating discharge section to help press the pleated filter paper into place. In addition, the press bar can be adjusted to match the thickness and type of filter media being processed.

The pressure bar improves pleat uniformity and minimizes excess material generated with each cycle by tightly packing and firmly pressing the pleats. In addition, the pressure bar’s adjustability allows fine-tuning to the specific requirements of the filter media, preventing over-compaction or deformation. At the same time, viewing windows are included in both the front and rear boxes of the machine, allowing the operator to closely monitor the pleating process. This transparency makes it easier for the operator to identify potential problems, adjust parameters, and ensure that the machine runs optimally.

High-precision pleating for superior filtration performance

The core function of any paper pleating machine is the ability to pleat filter media precisely and consistently. Dahe Intelligent’s machines use an advanced pleating mechanism that ensures that each pleat has the same size and spacing. For filtration to be effective, the pleats must closely space and evenly distribute across the filter surface. At the same time, the paper pleating machine ensures that each pleat forms with a high degree of precision, thereby increasing the surface area of the filter. The more uniform the pleats, the more efficient the filter is in capturing particles and contaminants, resulting in superior filtration performance. Therefore, whether it is an automotive air filter or an industrial fluid filtration system, consistently producing high-quality pleated filters is advantageous to meet stringent industry standards.

Increase production speed and efficiency

In today’s industrial environment, manufacturers must meet high filter requirements without compromising quality. Dahe’s intelligent paper pleating machine helps increase production speed without sacrificing the precision and quality of pleats. In addition, by adopting an advanced servo motor and stepper motor drive mechanism, the machine can complete the pleating cycle faster, achieving higher output in less time. Shorter production cycles increase production, which is especially beneficial for industries that require many filters. The efficiency gains brought by the paper pleating machine ensure that companies can promptly meet production quotas and needs, thereby improving overall operational efficiency and shortening customer delivery times.

Make the filtration process more efficient

The advanced features of the paper pleating machine include a servo motor-driven frame, adjustable pleat height, and a sophisticated pleating mechanism that improves the filtration process’s performance, efficiency, and sustainability. By better controlling the production of pleated filters, they can create filters with superior filtration performance, higher durability and reduced waste. So whether it is automotive air conditioning or other industrial applications, Dahe’s intelligent paper pleating machine provides a reliable solution to produce high-quality pleated filters, improving filtration efficiency and contributing to long-term operational success.