A suitable air filter pleating machine is critical for businesses specializing in air filter production. Air filter pleating machines significantly impact product quality, manufacturing efficiency, and overall operating costs. With various options available, understanding your business’s specific needs is essential to making the best choice. Many factors must be considered, from production volume to material compatibility and advanced automation features. This blog post will guide you through choosing the right air filter pleating machine for your business, helping you optimize performance and profitability.

Production Requirements for Air Filter Pleating Machines

The first step in choosing the right air filter pleating machine is to evaluate your production requirements. Start by determining the type of filter you produce, including its size, pleat size, and material composition. Different machines are designed to accommodate specific filter types, so matching the machine’s capabilities to your product range is crucial. Next, evaluate your production volume. If your business requires large-scale production, you need a high-speed pleating machine for continuous operation. For smaller or specialized production runs, a semi-automated machine may be sufficient. Also, consider the complexity of the desired pleat pattern. Machines with advanced pleating technology and servo-driven systems offer greater precision and flexibility, critical to producing high-performance filters.

Evaluating the Material Compatibility of an Air Filter Pleating Machine

Material compatibility is another important factor when selecting an air filter pleating machine. Air filters are made from various materials, including synthetic fibers, fiberglass, and paper-based media. Each material has unique characteristics and handling requirements that must be aligned with the machine’s capabilities. Certain materials may require precise tension control during the pleating process to prevent tearing or deformation. Other materials may require specialized heating systems to ensure proper bonding or forming. Therefore, when evaluating a machine, check that its specifications are compatible with the materials you are using. It is also beneficial to consult with the filter production equipment manufacturer to confirm that the machine can handle your specific filter media. A versatile pleating machine that can handle a variety of materials is a valuable asset for companies with a diverse product offering.

Automation Features of Air Filter Pleating Machines

Automation is essential in modern air filter manufacturing, increasing productivity and reducing labor costs. Advanced air filter pleating machines have various automation features, such as automatic feeding, cutting, and stacking systems. These features streamline the production process, minimize human intervention, and improve efficiency. When choosing a pleating machine, consider the level of automation that’s right for your business. Fully automated machines are ideal for high-volume production, providing steady output with minimal downtime. For companies focused on small-scale or custom production, semi-automated machines may offer the right balance between automation and manual control. In addition, machines with programmable settings provide greater flexibility and can be quickly adjusted to meet changing production needs.

Evaluate Energy Efficiency and Maintenance

Energy efficiency and maintenance requirements are key factors in determining the long-term cost-effectiveness of an air filter pleating machine. Energy-efficient machines are essential in today’s market. Machines with energy-saving features, such as optimized motor systems or advanced heating technology, can reduce energy consumption. Maintenance is another important consideration. Machines with simple modular designs are easier to maintain, reducing downtime and repair costs. In addition, choose machines made by reputable manufacturers who offer reliable after-sales support, including spare parts supply and technical assistance.

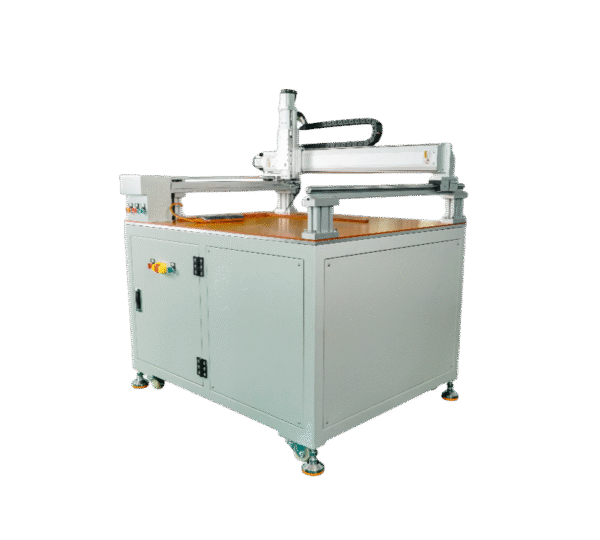

Work with a filter pleating machine manufacturer

The final step in choosing the right air filter pleating machine is to choose a reliable manufacturer. Trustworthy manufacturers offer high-quality machines, comprehensive support, and expert guidance to help you make an informed decision. In addition, consider requesting a demonstration or visiting the manufacturer’s factory to see the machine in action. This enables you to evaluate its performance and assess its quality. Dahe Intelligent can develop its research and development as a filter production equipment manufacturer and provide you with exclusive filter production equipment customized to your needs. At the same time, you can visit our factory to understand the production quality and operation of the equipment.

Choosing the right filter production equipment

Careful considerations are required when choosing filter production equipment, from product quality to operational efficiency. By understanding your production needs, evaluating material compatibility, considering automation functions, and working with trusted manufacturers, you can make a wise choice that meets your business goals.