Filter production equipment can provide high-performance and high-efficiency filters for different filtration industries. From household air conditioners to automotive air conditioners and other application scenarios, the durability and efficiency of filters directly affect the performance of these industries. For filter manufacturing companies, it is crucial to ensure that filter production equipment is durable and practical. This guide will discuss how filter equipment manufacturers ensure that production equipment meets these high standards and what methods and strategies are used.

Material Selection: Fundamental to Durability for Filter Equipment Manufacturers

Choosing the right materials is one of the most critical steps for a filter equipment manufacturer to ensure product durability and efficiency. The choice of materials used to build filter production equipment plays a vital role in its functionality and longevity under operating pressures. Environmental factors such as high temperature, moisture, and corrosive chemicals can significantly affect the durability of filter production equipment. Therefore, we choose corrosion-resistant materials such as stainless steel or specialized alloys. Manufacturers use advanced materials such as carbon composites and ceramics for extreme conditions, providing long-term durability without compromising performance. At the same time, by carefully selecting the right materials for each specific application, we ensure that their products are durable and capable of achieving high levels of productivity over an extended period of time.

Filter equipment manufacturers maximize efficiency with optimal features

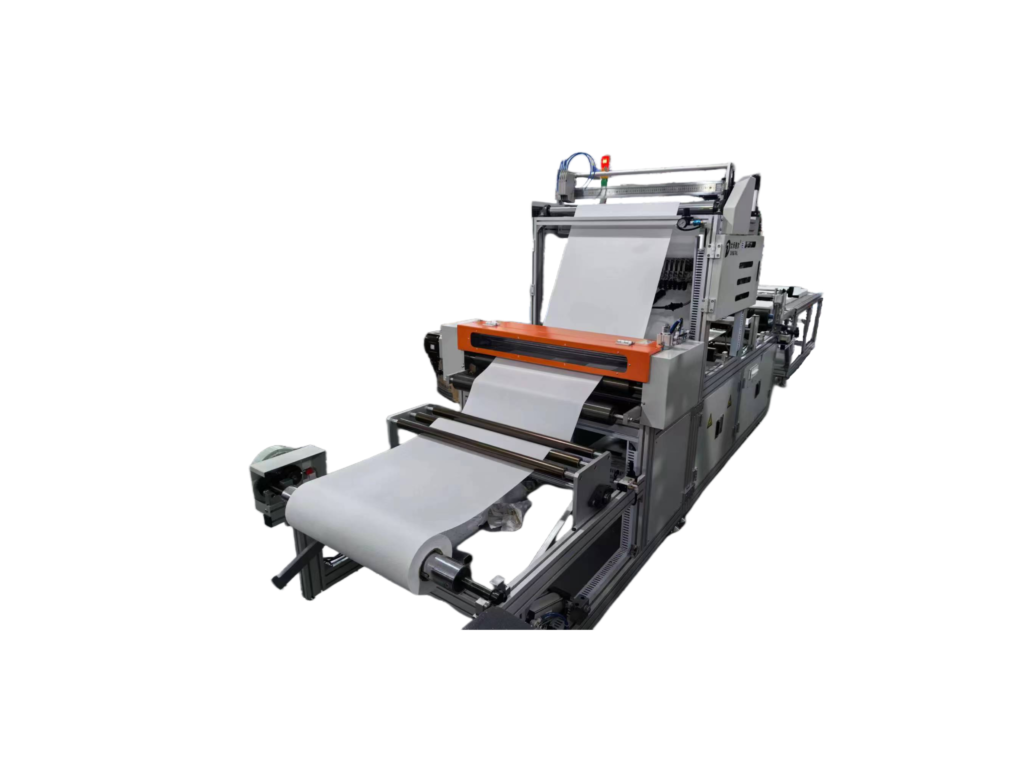

The design of filtration production equipment is also a key factor in determining product efficiency and durability. As a professional filter equipment manufacturer, we will focus on optimizing the design to maximize the working efficiency of the production equipment, enhance air or fluid flow, and reduce resistance without compromising filter effectiveness.

For example, in the glass fiber origami machine, a modern monitoring system automatically controls the tension so that the filter material does not break quickly during transportation and does not fall to the ground. The system uses an automatic feeding device, significantly reducing the operator’s fatigue. Degree of labor. The operating system will use A touchscreen interface to make operation intuitive and straightforward. Adopting these technologies not only ensures the machine’s long-term operation and improves efficiency but also improves the durability of the equipment by reducing the need for frequent replacement or maintenance.

Rigorous testing of filtration production equipment

Before any filtration production equipment can be put on the market, it must undergo rigorous tests to ensure it meets the necessary durability and efficiency standards. These tests simulate the operating conditions of a production filter in an actual environment, allowing manufacturers to identify potential weaknesses and improve product designs before series production. Filtration equipment manufacturers typically use state-of-the-art testing facilities with state-of-the-art technology to replicate conditions such as high flow rates and extreme operating conditions.

For example, we perform accelerated aging testing on filtration production equipment, exposing the equipment to conditions that simulate long-term use. This helps manufacturers evaluate a product’s durability and adjust materials or design if necessary. Efficiency testing also tests the equipment’s ability to produce filters of different materials based on application conditions. By conducting these comprehensive tests, you can ensure that equipment performs efficiently from the start and maintains its effectiveness and durability over the long term.

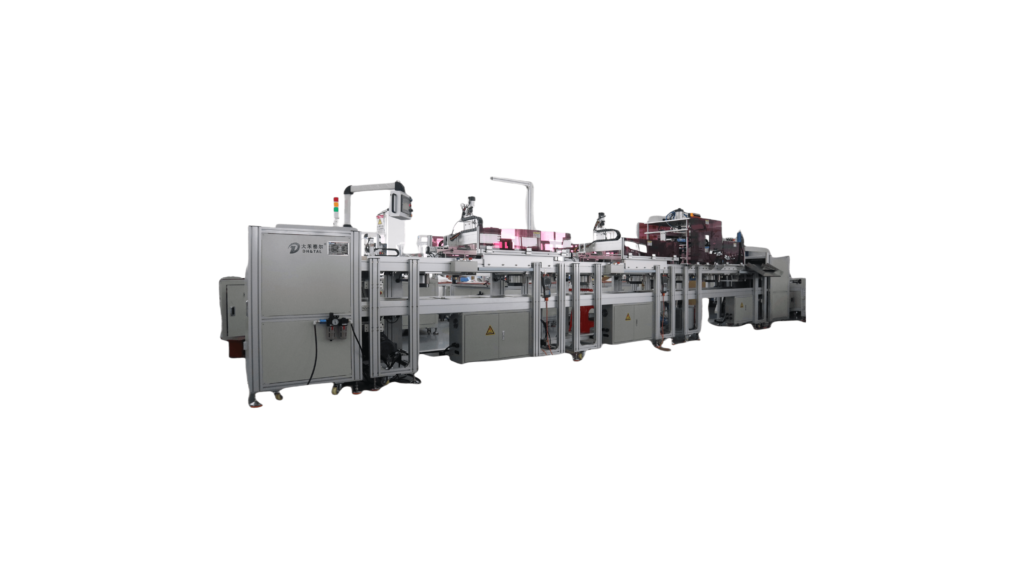

Customize equipment for specific applications

Every industry has unique filtration requirements, and as a filtration equipment manufacturer, we often provide customized solutions to meet our customers’ different needs. Customization ensures that filtration production equipment is efficient and durable, as different environments and applications require different filter designs and materials. Custom filtration equipment involves adjustments to dimensions, automation features, actuation methods, and more. We understand the specific needs of each application and then design filter production equipment that optimizes performance and longevity for that application. For example, designers must design HEPA filtration equipment to handle fine particles. Customization ensures the product perfectly suits the user’s needs, improving efficiency and durability.

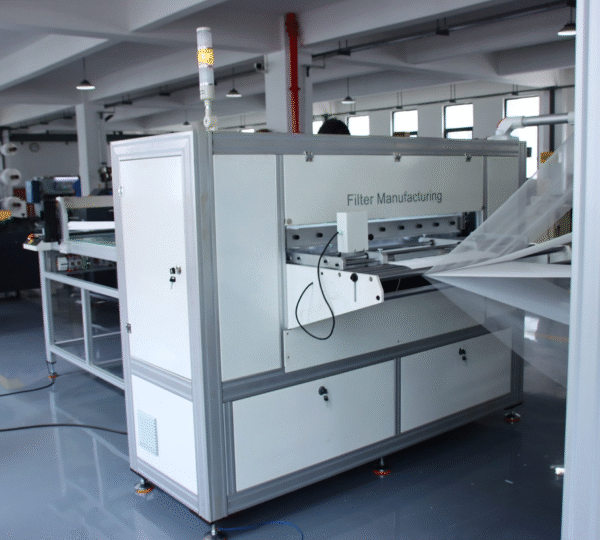

Regular maintenance and life cycle management

Even the most durable and efficient filter production equipment requires regular maintenance to maintain optimal performance. The service life of the equipment depends not only on the initial quality but also on how well the system is maintained throughout its life cycle. Dahe Intelligence will provide customers with maintenance services and comprehensive support, including routine inspections, parts replacement plans, and more. At the same time, we include a monitoring system in the filter production equipment we propose to alert users when the equipment is approaching the end of its service life or when parts need to be replaced.

Improve efficiency and durability in all aspects

Ensuring the durability and efficiency of filtration production equipment requires a multifaceted approach, including careful selection of materials, innovative design, and rigorous testing. Dahe Intelligence will strive to create products that meet the highest industry standards to ensure its customers benefit from reliable, durable, efficient filter production equipment.