The HVAC (Heating, Ventilation, and Air Conditioning) industry is evolving rapidly, and as a result, air filter production lines are adapting to meet new demands. With growing concerns about air quality and environmental sustainability, the need for high-performance filters has never been more pressing. In response to these challenges, air filter production lines are evolving, and manufacturers are refining their processes to deliver improved, more efficient products.

Rising Demand for High-Efficiency Filters

One of the most significant trends in the HVAC industry is the increasing demand for high-efficiency air filters. As air quality standards become more stringent, HVAC systems are required to filter out smaller particles, including dust, pollen, bacteria, and even viruses. This has led to the need for filters with higher MERV (Minimum Efficiency Reporting Value) ratings. To meet this demand, air filter production lines are being designed to produce filters with more layers and finer filtration media, ensuring superior air quality.

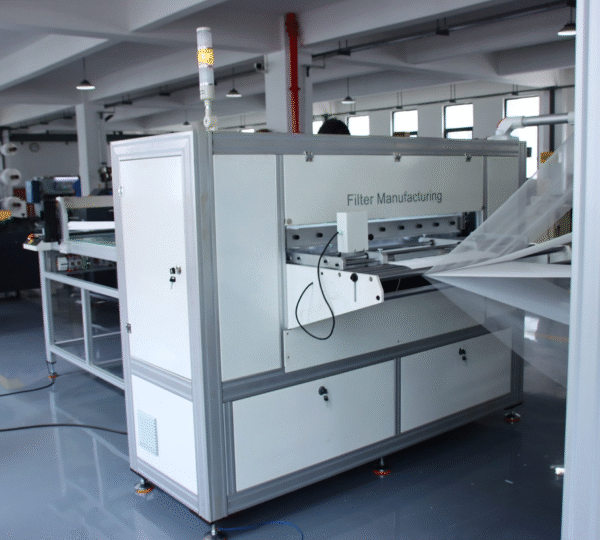

Automation in Air Filter Production Lines

Automation is a key factor in adapting Air Filter Manufacturing Lines to meet the needs of the HVAC industry. Automated systems help streamline the manufacturing process, improving efficiency and reducing labor costs. By incorporating robotics, conveyor systems, and AI-driven quality control, manufacturers can achieve higher precision and faster production times. Automation also enables better consistency in filter quality, which is crucial in industries such as HVAC, where performance standards are critical.

Customization for Specific HVAC Applications

With the HVAC industry serving a wide range of sectors—from residential to commercial and industrial—there is a need for customized air filters. Air Filter Manufacturing Lines are adapting by offering a variety of filter sizes, shapes, and materials to meet specific HVAC requirements. Whether it is filters designed for high-velocity air systems or those suited for commercial buildings with high pollutant levels, production lines are increasingly flexible in meeting the diverse needs of HVAC clients.

Integration of Sustainable Practices

Sustainability is a growing concern across all industries, and the HVAC sector is no exception. As consumers demand more environmentally-friendly solutions, air filter production lines are incorporating sustainable practices. For example, many manufacturers are using recyclable materials for filter frames and components. Additionally, production lines are focusing on reducing waste by improving material efficiency, optimizing the use of raw materials, and adopting energy-saving technologies in the manufacturing process.

Improved Filtration Media Technology

To meet the growing demand of the HVAC industry for improved filtration, air filter production lines are increasingly utilizing advanced filtration media technology. New materials, such as electrostatically charged fibers and nanofiber technologies, allow filters to trap smaller particles more effectively. These materials offer higher filtration efficiency while maintaining adequate airflow, which is crucial for HVAC systems. Manufacturers are investing in research and development to stay ahead of the curve and provide high-performance filters that meet the growing need for clean air.

Meeting Health and Safety Standards

Health and safety regulations are stricter than ever in the HVAC industry. Air Filter Manufacturing Lines are adapting by ensuring that their products meet or exceed industry standards for air quality and performance. This includes compliance with guidelines set by organizations such as ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) and the EPA (Environmental Protection Agency). Filters produced today must not only perform efficiently but also contribute to the overall safety and well-being of individuals in various indoor environments.

Faster Turnaround Times and Increased Production Capacity

The HVAC industry requires prompt delivery times, particularly during peak demand seasons such as summer and winter. Air filter production lines are being optimized for faster turnaround times without compromising quality. By improving production flow, reducing downtime, and increasing automation, manufacturers can meet tight deadlines and respond quickly to market demands. This increased production capacity helps meet the needs of HVAC companies that rely on a steady supply of high-quality filters.

Air Filter Production Lines Adapting to the HVAC Industry

Air filter production lines are evolving to meet the growing demands of the HVAC industry for high-efficiency filters, sustainability, and customization. In addition, automation, advanced filtration technologies, and improved manufacturing processes are essential for delivering the high-performance products the HVAC industry demands. Furthermore, as the HVAC industry continues to prioritize air quality and energy efficiency, air filter production lines will remain a critical component in ensuring the reliability and effectiveness of modern HVAC systems.