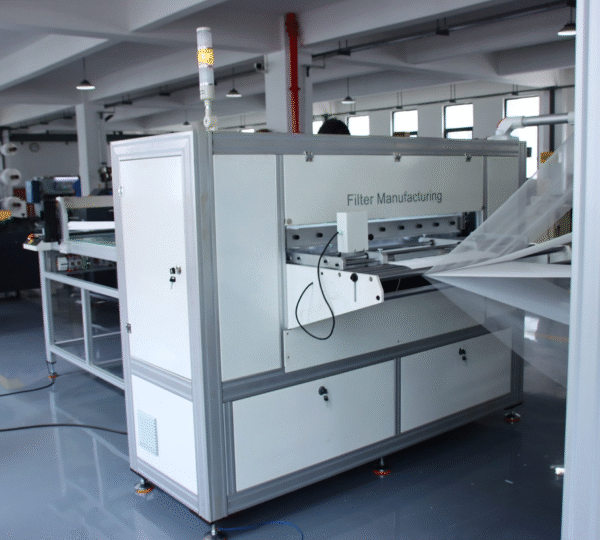

A Filter Glue Application Machine is a key piece of equipment in filter manufacturing for automotive, HVAC, and water purification industries. It precisely dispenses adhesive onto filter elements, ensuring a uniform bond and consistent product quality. The machine usually integrates glue melting, temperature control, and automated dispensing systems. However, even well-built machines are not immune to problems caused by high workload, inconsistent glue viscosity, or improper maintenance. By understanding how the machine functions—especially its pump, nozzle, and heating system—operators can easily spot early signs of malfunction before production is affected.

Uneven Glue Application

Uneven coating is one of the most common issues. You might notice irregular glue lines, weak bonding areas, or over-glued spots. These problems often come from incorrect pressure calibration, contaminated glue, or a partially clogged nozzle. To fix it, clean the nozzle with a compatible solvent after every production shift. Then, check the pump’s output consistency using a flow test—any fluctuation above 5% indicates a calibration issue. Maintaining glue temperature between 180°C and 200°C helps stabilize viscosity, ensuring smooth and even dispensing. Some operators also install flow sensors to adjust pump speed in real time automatically.

Glue Leakage and Overflow Issues

Glue leakage usually happens at connection points or near the nozzle due to worn seals, loose fittings, or excessive internal pressure. Over time, adhesive buildup around the joints worsens the problem. Routine inspection can prevent this: replace seal rings every 800 operating hours and inspect the tubing weekly for cracks or deformation. For overflow issues, monitor the pump pressure and ensure it stays below the glue supplier’s recommended limit (typically 0.4–0.5 MPa). If the leakage persists, inspect the heating chamber for glue residue; buildup can cause backpressure and uneven output.

Irregular Temperature Control

Temperature fluctuations directly impact glue viscosity and adhesion strength. When the glue overheats, it carbonizes and clogs the nozzle; when it’s too cool, it thickens and won’t flow smoothly. Most Filter Glue Application Machines come with dual temperature sensors, but they can drift over time. You should calibrate them at least once every 1,000 operating hours. Installing a backup sensor or using a digital infrared thermometer can verify the accuracy of measurements. Keeping the temperature within ±2°C of the set point ensures consistent bonding. A stable thermal environment also extends heater lifespan by nearly 20%.

Air Bubbles in Glue Lines

Air bubbles in the glue line lead to weak filter joints and visible defects in the final product. This typically happens after refilling the glue tank or when air seeps into the feed hoses. Always bleed the system thoroughly after each refill and use vacuum degassing if possible. For manual systems, operators can tilt the tank slightly to help trapped air escape. Modern Filter Glue Application Machines often include an automatic degassing unit, which eliminates up to 90% of bubble-related defects. As a general rule, even 0.5% trapped air can reduce bonding strength by up to 15%, according to filter manufacturing data from Parker Hannifin.

Clogging and Glue Solidification

When production pauses or the machine remains idle, the glue can cool and solidify in hoses or nozzles. This causes flow interruption and can damage internal valves during restart. The solution is preventive cleaning—purge the glue with a compatible cleaner before shutdown, and use the “standby heating” mode if the machine supports it. Gradual reheating is better than sudden temperature spikes, which may crack PTFE-lined hoses. Maintaining a controlled environment temperature between 20°C and 28°C also reduces the risk of solidification, especially when using polyurethane-based adhesives.

Electrical and Control System Failures

Electrical problems are less visible but often more disruptive. Faulty sensors, damaged wiring, or PLC malfunctions can stop production entirely. Regularly check all wiring for wear and corrosion, and back up the machine’s software settings monthly. When error codes appear on the control screen, consult the manufacturer’s diagnostics menu before resetting the system. Using voltage stabilizers and surge protectors can prevent electrical spikes from damaging control boards. In one real-world case study by Henkel, downtime caused by electrical faults dropped 35% after implementing regular firmware updates and surge protection.

Keeping Your Filter Glue Application Machine Running Smoothly

Maintaining Filter Glue Application Machines is about prevention, not just repair. Establish a maintenance plan that includes nozzle cleaning every shift, seal replacement every six months, and software calibration quarterly. Provide training for operators to help them understand glue behavior, as most problems stem from improper handling. Keep spare parts like heating elements, seals, and hoses on-site to minimize unplanned downtime. With consistent attention, your machine can deliver steady performance, reduce adhesive waste by up to 10%, and ensure each filter meets quality standards. A well-maintained glue application system doesn’t just save money—it guarantees the reliability your production line depends on.