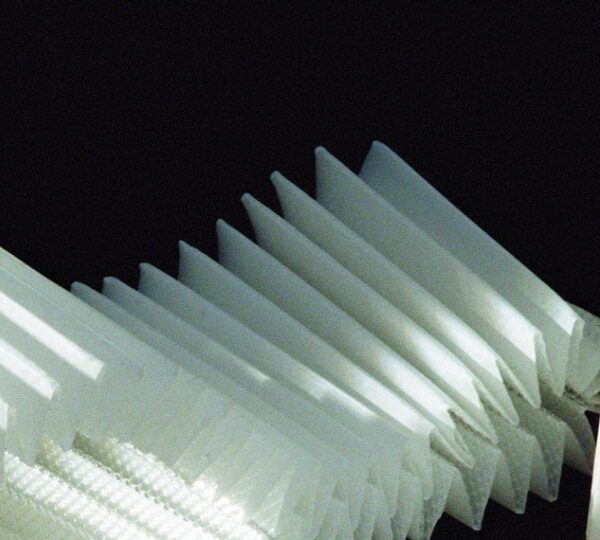

Pleating is a crucial step in the production of air filters, especially for HEPA and HVAC applications. It determines the surface area, airflow resistance, and overall filter efficiency. A well-pleated filter media ensures higher dust-holding capacity and longer service life. For manufacturers, selecting the appropriate paper pleating machine is crucial.

Types of Pleating Technologies

Different pleating methods suit different filter designs. The most common types are knife pleating, rotary pleating, and servo-driven pleating. Knife pleating machines are cost-effective and flexible for various filter sizes. Rotary pleating systems, on the other hand, excel in the high-speed production of uniform pleats, making them ideal for mass manufacturing of HVAC filters.

For HEPA filters, which require tighter tolerances and deeper pleats, servo-driven pleating machines offer superior control. These systems allow precise adjustment of pleat depth and pitch through automated settings, reducing setup time and material waste. Choosing the right technology depends on both production volume and the desired filter specifications.

Key Performance Parameters

When evaluating pleating equipment, manufacturers should focus on three key parameters: accuracy, speed, and stability. Accuracy ensures consistent pleat depth and width, which directly impacts airflow and dust capture efficiency. Speed determines throughput, crucial for large-scale HVAC filter production.

Stability is equally important. A machine that vibrates or overheats during operation can cause misalignment or material distortion. Reliable Paper Pleating Machines maintain uniform pleats across long production runs, ensuring every filter meets quality standards.

Material Compatibility and Flexibility

HEPA and HVAC filters utilize a wide range of media, including glass fiber, synthetic paper, melt-blown layers, and composite laminates. Each material behaves differently during pleating. A suitable pleating machine must be able to handle a wide range of thicknesses, coatings, and thermal sensitivities without tearing or wrinkling.

Advanced pleating machines come with adjustable tension control and temperature-regulated folding blades. These features allow seamless switching between materials without recalibration. For example, when producing glass fiber HEPA filters, gentle handling is crucial to prevent fiber breakage, which can compromise filtration performance.

Automation and Integration in Production Lines

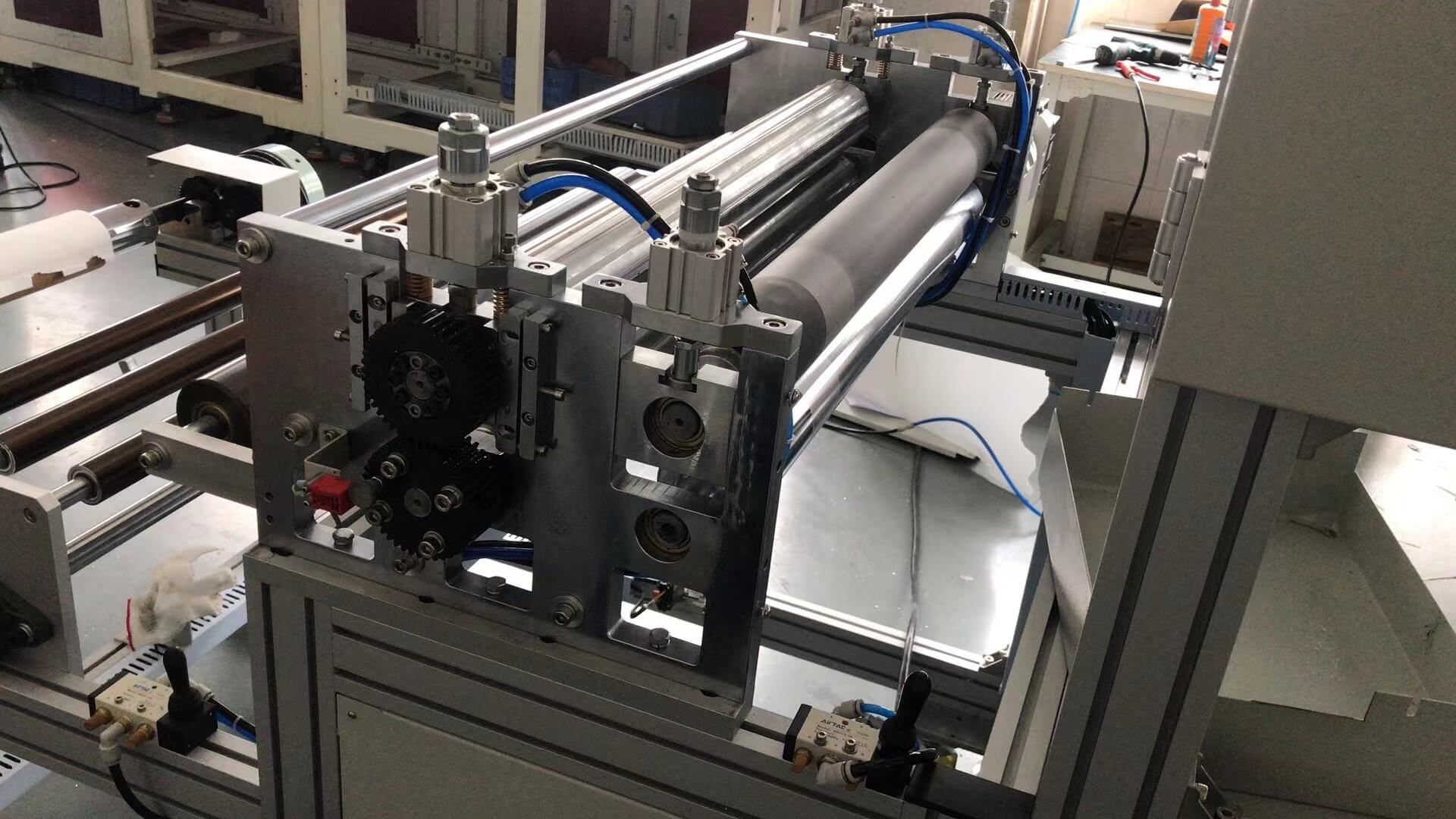

Automation has become a game-changer in the filter manufacturing industry. Modern pleating systems integrate with feeding, gluing, curing, and cutting modules to form a continuous production line. Automated Paper Pleating Machines reduce human error, maintain consistent pleat geometry, and lower labor costs.

For HVAC filter manufacturers operating 24/7, automated stackers and online curing systems significantly improve productivity. Integration with PLC and IoT systems enables real-time performance tracking, predictive maintenance, and remote control—essential for modern smart factories.

Quality Control and Testing Features

High-end pleating machines now include built-in inspection systems. Optical sensors and laser measurement tools verify pleat pitch and alignment during operation. This real-time quality feedback helps detect issues before they affect entire batches.

Some systems can automatically adjust pleating parameters to maintain accuracy. For example, a feedback-controlled servo pleating system may correct pleat deviation instantly, ensuring 100% consistency. Such features not only enhance production quality but also reduce material waste and downtime.

Real-World Application Example

A European air filter manufacturer recently upgraded its manual pleating setup to a fully automated servo-controlled line. The new system increased production efficiency by 35% and reduced pleat deviation from ±1.5 mm to ±0.3 mm. Energy consumption also dropped by 20% due to optimized servo motion control.

This upgrade improved HEPA filter uniformity and reduced the rejection rate. It also helped the company meet tighter EU air quality regulations. The case illustrates how investing in the right Paper Pleating Machine can yield long-term gains in performance, compliance, and profitability.

The Future of Paper Pleating Machine Technology

As demand for cleaner indoor air and energy-efficient filtration grows, pleating technology continues to evolve. Future Paper Pleating Machines will feature AI-driven monitoring, self-calibrating mechanisms, and predictive maintenance capabilities. Manufacturers will achieve even higher precision while minimizing downtime and resource use.