In the field of filtration, whether it is industrial, automotive, household, or other scenarios, filters’ materials and sizes vary. Therefore, many filter manufacturers will choose to produce filters customized to meet the market’s diverse needs, and this filter manufacturing equipment must be flexible enough to handle different materials and produce filters of various sizes. This requires filter manufacturers to be able to develop and produce advanced and adaptable filter production equipment. So that they can handle a variety of filter types, materials, and sizes while maintaining efficiency and high-quality output. Therefore, in this guide, we will introduce you to how Dahe Intelligent’s equipment can meet the production of filters of different sizes and materials.

Filter Manufacturing Equipment Capable of Handling Diverse Materials

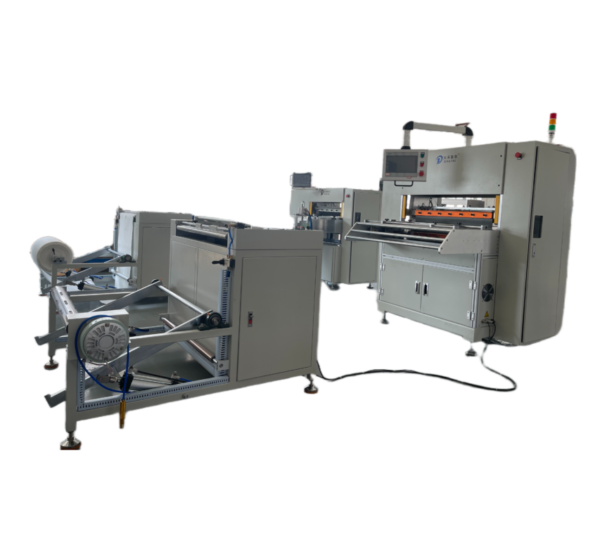

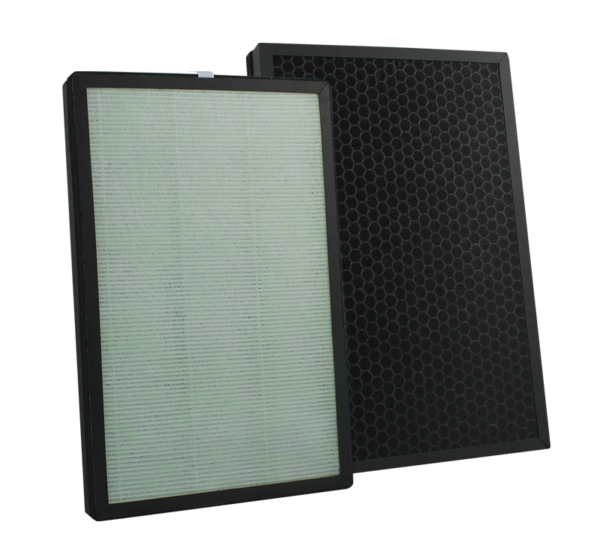

Dahe Intelligent designs its filter manufacturing equipment to handle a variety of materials, each with its unique characteristics and processing requirements. Manufacturers use various materials to produce filters, such as paper, glass fiber, activated carbon, etc. Their versatility lies in their ability to process these different materials accurately and efficiently. For example, a Paper pleating machine ensures that the paper forms and pleats accurately without damaging the fibers. In addition, an automatic filter element taping machine can continuously apply glue and glue the edge strips on the long side for some small filter element taping. Customizable settings and modular components used in all filter manufacturing equipment can be customized to different sizes and quickly adapt to other material types. This flexibility allows manufacturers to produce various filters, from simple air filters to highly specialized water or oil filters used in critical industries.

Flexible handling of filter customization and standard sizes

As mentioned above, Dahe’s intelligent filter manufacturing equipment can also produce filters of various sizes. The size of the filter depends on its intended use, and the same machine must be able to adjust to make filters for different industries. This manufacturing equipment that adapts to different filter sizes usually includes adjustable components such as pleating rollers, cutting stations, and forming machines. These adjustments allow manufacturers to produce filters of various sizes without sacrificing precision or quality.

The key to successfully producing filters of various sizes is modular equipment, which can be customized to the size of the equipment according to specific production requirements. This flexibility reduces the need for multiple machines, and by quickly adjusting machine settings or replacing parts, manufacturers can efficiently produce filters of different sizes, ensuring the highest performance and reliability standards.

Intelligent technologies in filter manufacturing equipment

Modern filter manufacturing equipment often uses intelligent technologies to improve performance, efficiency, and quality. Automatic feeding devices, modern monitoring systems, servo motors, etc., make operation simple, easy to adjust, smooth transmission, and more accurate production dimensions. Modern monitoring systems automatically control the tension to prevent the filter material from breaking or dropping during transportation. The automatic feeding device dramatically reduces the operator’s labor. A servo motor drives the whole machine, making it operate smoothly and ensuring product size accuracy. The operating system of the whole equipment adopts a touchscreen interface, making the operation intuitive and straightforward. With the growing demand for large-scale, customized-size filters in industries such as automobiles and household air conditioners, adopting these technologies also ensures high standards and high-efficiency production.

Customization and integration of special filters

For companies that produce specialized filters, customizing filter manufacturing equipment is critical. Customizable filter manufacturing equipment enables customized production lines to accommodate a variety of design specifications. For example, the equipment can be adjusted to manufacture filters with unique shapes (cylindrical or pleated designs) or use composite materials requiring specific processing technology. In addition, integrating technologies such as ultrasonic welding or heat sealing can further enhance the customization process, ensuring that the filter components are firmly bonded without compromising the integrity of the material. Customizable machines also benefit manufacturers when they must produce limited quantities of highly specialized filters.

Quality Control for Filters

Quality control is critical in filter production, especially when dealing with various materials and sizes. Designers often equip filter manufacturing equipment with built-in quality control systems to ensure every filter meets the required specifications. These systems monitor vital factors such as material consistency, dimensional accuracy, pleat count, and seal integrity. In contrast, equipment with sensors, cameras, and automated inspection systems can detect even the slightest defects in filter materials or design. This ensures that the company delivers only high-quality filters to customers, helping to establish a reputation for reliability and precision. In addition, they can subject filters to rigorous testing, such as airflow testing, filtration efficiency testing, and pressure drop testing, to ensure that filters perform at their best.

Filters That Handle a Variety of Different Material Sizes for You

Filter manufacturing equipment can handle filters made from various materials and sizes. It offers the flexibility, precision, and efficiency needed to meet today’s diverse market needs, from paper to synthetic fibers and composites. By integrating innovative technology, customizable features, and quality control systems, manufacturers can produce high-quality filters for various applications without sacrificing performance.