Air Filter Production Line drives reliable filtration by forming, sealing, and testing every unit with precision. Clean air does more than protect comfort—it protects productivity, compliance, and long-term equipment reliability. In modern buildings, industrial plants, medical facilities, and cleanrooms, airborne contamination directly affects health, process yield, and operating costs. A well-engineered Air Filter Production Line transforms raw filtration media into precision air-control products that deliver predictable airflow, high dust-holding capacity, and stable pressure performance throughout their service life. When manufacturers invest in an advanced Air Filtration Equipment System, they gain the ability to produce filters that perform the same in real installations as they do in laboratory certification tests

Air Filter Production Line Architecture Builds Dimensional Accuracy

Every high-performance filter begins with mechanical stability. The uses rigid frames, servo-driven conveyors, and synchronized motion control to keep filtration media flat, centered, and under controlled tension. Each Air Filtration Equipment System moves materials through cutting, pleating, stacking, and framing without introducing distortion. This structural precision allows the Air Filter Production Lines to hold tight tolerances on filter thickness, frame size, and media alignment. When filters fit their housings perfectly, they maintain uniform airflow and prevent leakage around the edges. This accuracy directly improves filtration efficiency and reduces pressure drop variability across large installations.

Precise Control of Fiber Distribution and Media Density

Filtration performance depends on how fibers interact with airborne particles. The controls fiber density, layer spacing, and surface uniformity as media moves through the Air Filtration Equipment System. Automated feeding and layering systems prevent compression, wrinkles, and uneven stacking. By maintaining precise porosity and thickness, it ensures that air is distributed evenly across the filter surface. This balanced airflow increases dust-holding capacity, slows clogging, and extends service intervals. Customers benefit from lower energy consumption and fewer filter replacements.

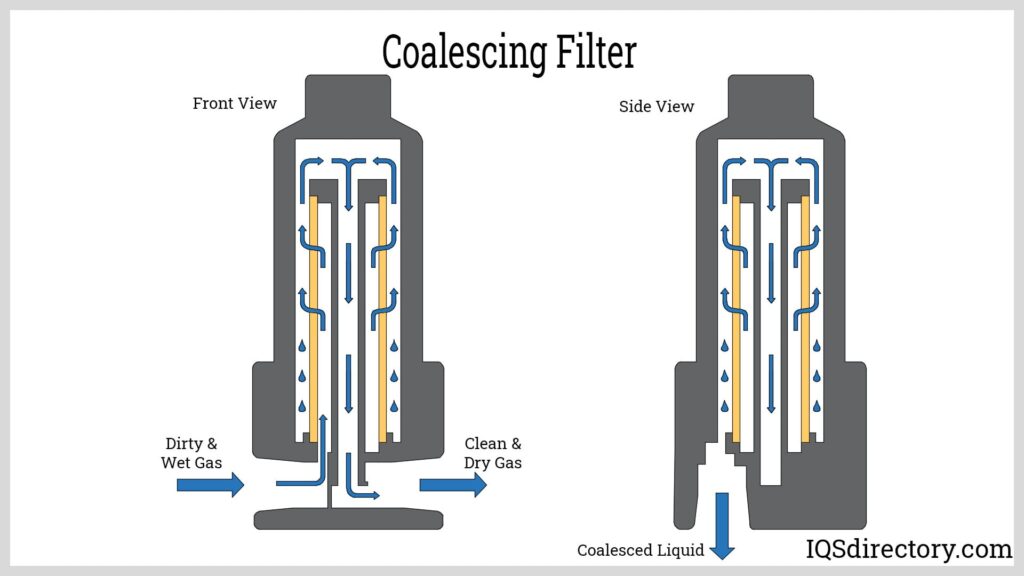

Air Filter Production Line Eliminates Bypass Leakage

No filter can perform well if air bypasses the media. It addresses this risk by integrating frame molding, adhesive application, and gasket installation into a single controlled process. Each Air Filtration Equipment System applies consistent pressure and curing time to create airtight seals. This approach produces filters that resist vibration, thermal expansion, and long operating hours. Because it creates a closed airflow path from intake to exhaust, every particle must pass through the filtration media rather than escape around it.

Automation Ensures Stable and Consistent Production

Automation allows them to produce millions of filters with identical performance. Robotics, machine vision, and digital control platforms coordinate every Air Filtration Equipment System. Sensors track media alignment, adhesive volume, and frame position in real time. This level of automation prevents variation between production batches. It also allows manufacturers to scale output without sacrificing quality. Customers receive filters that perform the same way regardless of production date or volume.

Air Filter Production Line Integrates Inline Performance Verification

Testing inside confirms that every filter meets design targets. Inline airflow, pressure drop, and leakage measurement stations verify performance before packaging. Each Air Filtration Equipment System records results and assigns them to a unique product ID. This traceability allows manufacturers to guarantee compliance with filtration standards and customer specifications. It also enables rapid root-cause analysis if any performance issue appears in the field.

Air Filter Production Line Improves Manufacturing Efficiency

A modern approach reduces waste, energy use, and labor costs. The Intelligent Air Filtration Equipment System software adjusts machine speed, heating levels, and adhesive flow in response to real-time production conditions. This efficiency reduces operating costs while maintaining high quality. Manufacturers gain a competitive advantage by delivering high-performance filters at lower total production cost.

Air Filter Production Line Builds Long-Term Brand Reliability

Customers depend on air filters to protect people, equipment, and processes. A precision-engineered Air Filter Production Line ensures that every filter meets that responsibility. Each Air Filtration Equipment System supports stable airflow, high particle capture, and strong mechanical integrity. When filters perform reliably in hospitals, factories, and cleanrooms, customers associate that success with the manufacturer behind them. Over time, this consistency builds trust, repeat business, and brand authority.