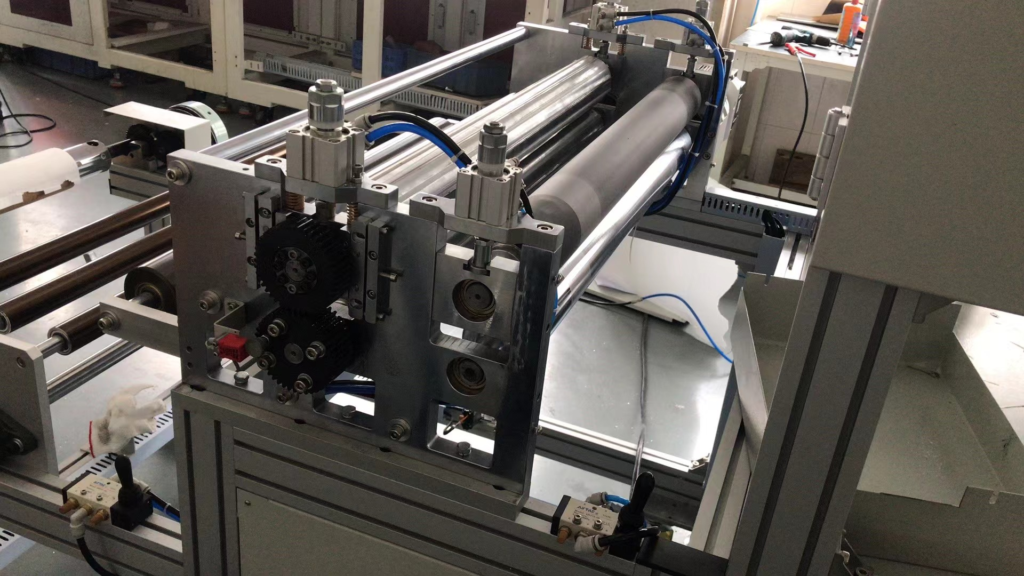

Manufacturers today face higher performance requirements from HVAC, commercial air cleaning, and industrial filtration markets. Consistent pleat geometry is no longer optional. Uneven pleats affect airflow resistance, dust-holding capacity, and final filter life. Manual and semi-automatic operations struggle to keep tight tolerances. Automated lines solve this problem by maintaining stable pleat height, pitch, and compression. Advanced servo controls keep variation below ±0.2 mm. This accuracy remains stable even during long production runs. As a result, more factories are shifting to an automated Air Filter Pleating Machine to ensure consistent product quality.

Boosting Throughput for High-Capacity Production

Speed matters in high-volume environments. An automated pleating machine runs faster because operators supervise rather than constantly adjust settings. Many modern systems operate at 20–35 meters per minute, depending on the filter media. Manual or semi-automatic lines usually deliver half this speed. Higher throughput helps manufacturers respond to seasonal HVAC demand without adding new shifts. Labor savings are clear, too. One operator can manage an automated module that previously required multiple workers. This labor efficiency gives manufacturers a direct advantage during periods of tight workforce availability.

Reducing Waste Through Smarter Control

Filter media costs remain high, especially for synthetic fibers, melt-blown layers, and HEPA-grade materials. Scrap quickly becomes expensive. Automated systems reduce waste by using precise feed motors, controlled heating zones, and stable folding pressure. Sensors track media position in real time. If tension drifts, the system corrects instantly. Many factories report double-digit reductions in waste after switching. The benefit is simple. Each pleat lands exactly where it should. The controlled process prevents tearing and avoids pleat deformation, which often occurs during manual operation.

Supporting a Wider Range of Filter Designs

Most manufacturers produce more than one type of filter. Air intake elements, HVAC filters, industrial dust cartridges, and cabin air filters all require different pleat characteristics. Automated systems make it easy to switch between these types. Operators store recipes for pleat height, knife temperature, feed speed, and pitch. Switching from one product to another takes seconds, not an extended manual setup. Servo-driven knife pleating, rotary pleating, and hybrid mechanisms offer greater flexibility in product design. This versatility allows manufacturers to expand their catalog without expanding labor or floor space.

Improving Filter Performance for HEPA and High-Efficiency Media

HEPA and high-efficiency filters need perfect pleat uniformity. Even minor deviations affect airflow and pressure drop. Automated pleating machines deliver stable heating, tension, and compression. These machines protect sensitive materials like glass fiber and high-efficiency synthetic layers. Many feature closed-loop monitoring that corrects deviations in real time. Manufacturers that supply healthcare, cleanrooms, or semiconductor facilities depend on these capabilities. Automated Air Filter Pleating Machine technology helps them maintain compliance with EN 1822 and ISO 29463 standards. For companies competing in high-end markets, this performance becomes a key reason to automate.

Lower Maintenance Demands and More Reliable Output

Automation reduces the unpredictability of production. Modern pleating systems include predictive maintenance tools that track wear, servo performance, and lubrication schedules. Operators receive alerts before problems appear. This reduces unexpected downtime and extends machine life. Stable operation also improves OEE, which remains a significant performance metric across large plants. Automated systems run smoothly because they rely on controlled motion instead of manual pressure adjustments. This long-term reliability attracts manufacturers that operate continuous multi-shift production lines.

Easier Integration With Automated Downstream Modules

Pleating is only one step in filter manufacturing. Many companies now integrate automated pleating with trimming, curing, pleat bonding, and stacking modules. These downstream units communicate via a single PLC. The whole line moves material from roll to completed packs with minimal human handling. This lowers defect rates and increases throughput. When integrated well, an Air Filter Pleating Machine becomes the core engine of the entire production line. This trend continues to grow as factories pursue end-to-end automation to satisfy rising demand.

Conclusion and the Value of Automated Air Filter Pleating Machine Systems

Manufacturers prefer automated Air Filter Pleating Machine systems because they deliver accuracy, speed, and stable quality. These systems reduce labor needs, lower scrap, and support complex filter designs. They also align with global performance expectations for HVAC, industrial, and HEPA markets. As demand increases, automation enables factories to achieve consistent output and predictable cost control. For companies looking to scale efficiently, automated pleating systems provide a reliable path forward.