Large-scale production facilities operate continuously, often processing tons of material every hour. In these environments, even a short downtime can cost thousands of dollars. Air and liquid filtration systems play a critical role in keeping machines clean, maintaining product quality, and ensuring compliance with environmental regulations. However, manual filter management struggles to keep up with the speed and complexity of high-capacity operations.

That’s why automation has become essential. Filtration Automation integrates sensors, control systems, and intelligent cleaning cycles to maintain filter performance without constant human supervision. It ensures filters are cleaned or replaced at the right time, minimizing disruptions and optimizing system efficiency.

Consistency and Quality Control

Manual filter maintenance introduces human error. Workers may overlook pressure drops, forget cleaning intervals, or replace filters too early or too late. Automation eliminates this uncertainty. With real-time monitoring, systems automatically adjust cleaning frequency and airflow rates based on actual conditions.

This consistency ensures product quality stays stable. For example, in the food and beverage industry, even small contamination can cause production losses. Automated filtration keeps air and liquid purity levels within strict limits, meeting ISO and FDA standards while reducing operator workload.

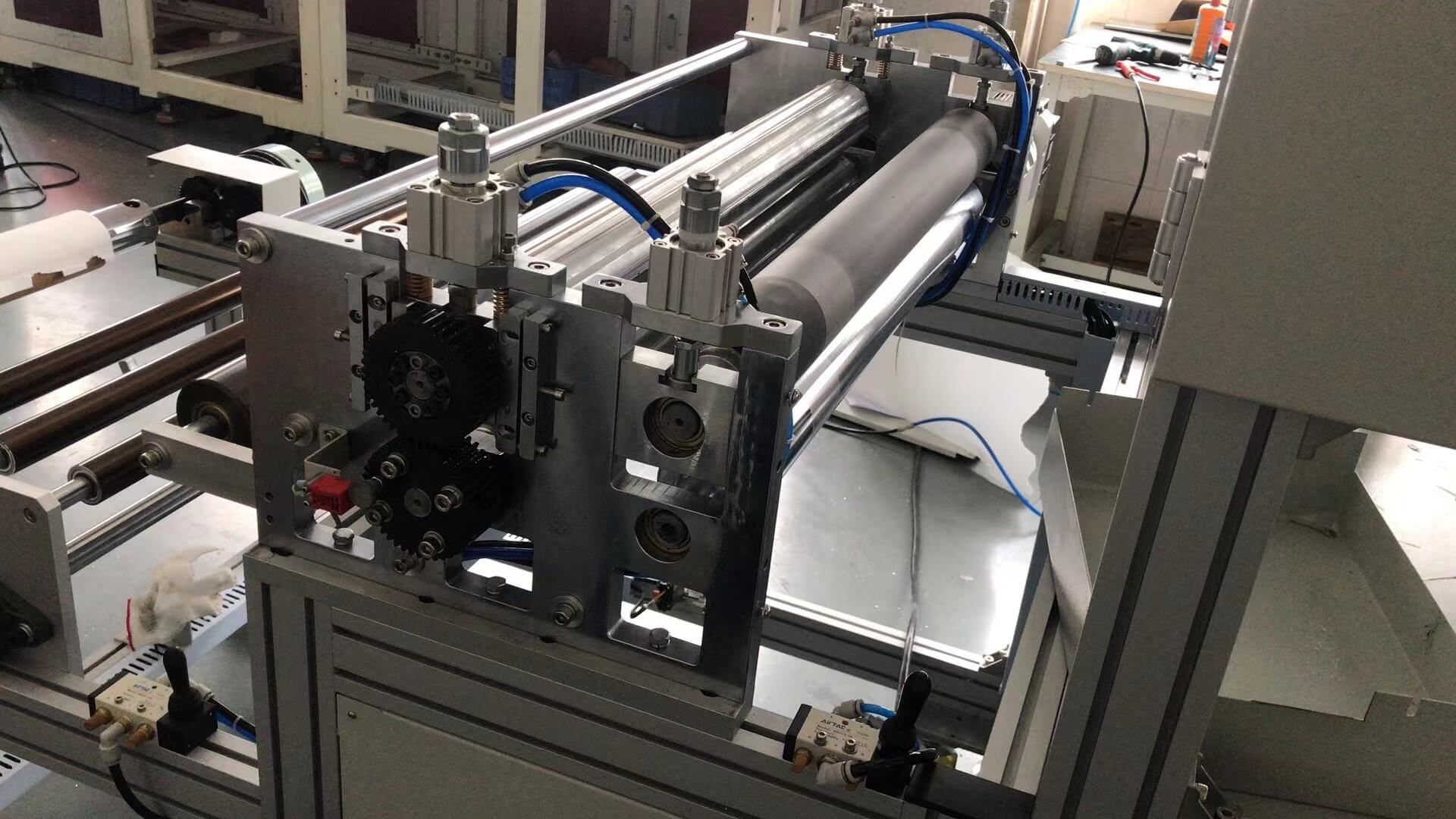

Improved Efficiency Through Smart Control Systems

Automation optimizes the entire filtration cycle. Sensors track differential pressure, dust accumulation, and flow rates. When the system detects a performance decline, it triggers automatic cleaning or adjusts fan speed. This reduces wasted energy and prevents premature filter wear.

Modern PLC and IoT-based filtration systems allow managers to monitor performance remotely. In some facilities, automated filter cleaning reduced energy use by up to 20% and extended filter life by 50%. These improvements translate directly into higher uptime and lower operational costs.

Reducing Downtime and Maintenance Costs

In high-capacity facilities, downtime can be disastrous. A packaging plant or chemical factory may lose tens of thousands per hour if filters clog unexpectedly. Automated systems prevent such failures through predictive maintenance.

By analyzing sensor data, Filtration Automation predicts when filters need cleaning or replacement. Maintenance teams can act before blockages occur. The result is a smoother production flow, fewer unplanned shutdowns, and significant cost savings over time.

Enhancing Worker Safety and Compliance

Dust, fumes, and fine particles pose serious health risks in industries like metalworking, pharmaceuticals, and cement production. Automated filtration systems keep air clean without exposing workers to hazardous materials.

These systems also simplify compliance with occupational safety and environmental standards. For example, U.S. OSHA regulations limit exposure to respirable dust to 5 mg/m³. Automation helps maintain these limits consistently by automatically controlling airflow, cleaning intervals, and emissions.

Energy Optimization and Sustainability

Energy consumption is one of the largest costs in industrial filtration. Constant fan operation wastes power and shortens equipment life. Automated systems use variable-frequency drives (VFDs) to adjust fan speeds in real time based on actual airflow resistance.

This approach cuts unnecessary energy use while maintaining the required filtration performance. According to the U.S. Department of Energy, VFD implementation can reduce fan energy consumption by up to 30%. Combined with intelligent filter cleaning, Filtration Automation contributes to greener, more sustainable production.

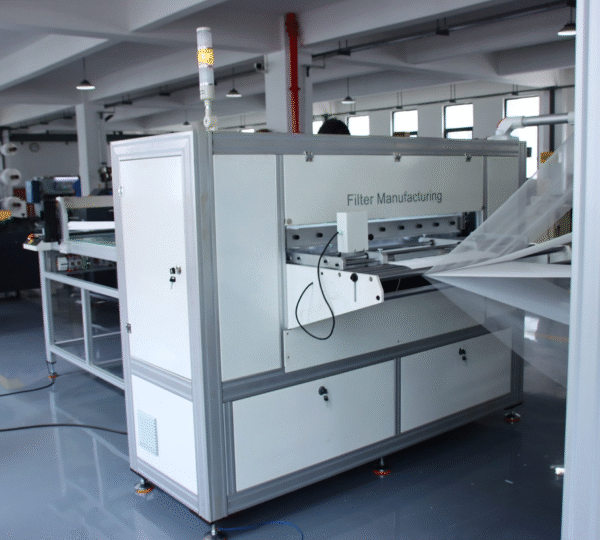

Real-World Application Example

A leading German automotive parts manufacturer adopted an automated filtration system across its painting and coating lines. The system used pressure sensors and automated pulse cleaning to manage filter loading. As a result, filter life increased by 45%, and maintenance costs dropped by 25%.

The company also improved air quality in its production hall, reducing particle concentration below 0.1 mg/m³. This upgrade helped them meet stricter EU environmental standards while improving worker comfort and process reliability.

The Future of Filtration Automation in Industry

The growing scale of manufacturing means manual filtration management is no longer enough. Automation delivers consistency, safety, and efficiency that human operators can’t match. As AI and predictive analytics advance, Filtration Automation will become even more intelligent—capable of self-optimizing cleaning cycles and anticipating filter degradation before it happens.