Month: October 2025

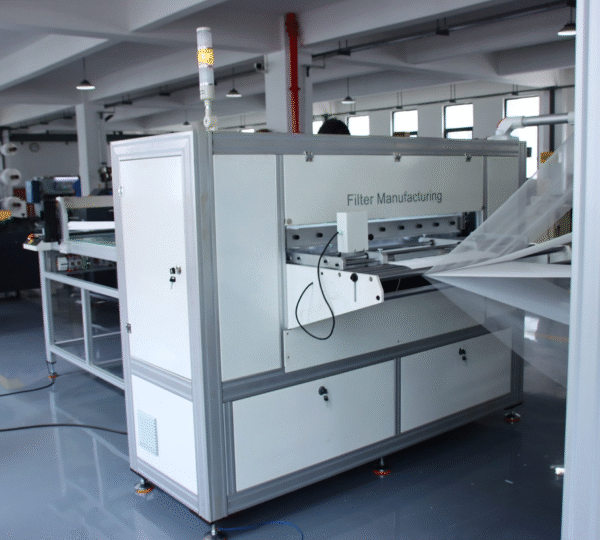

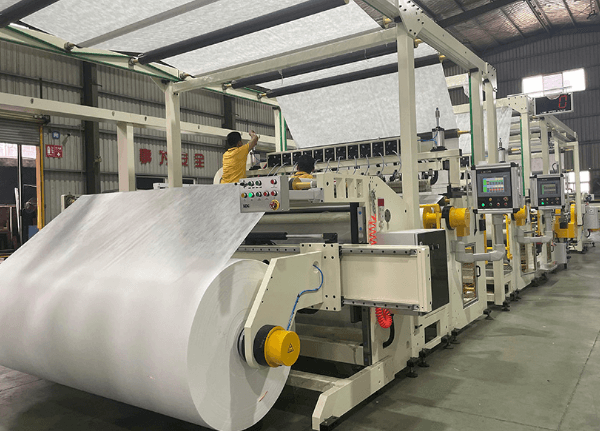

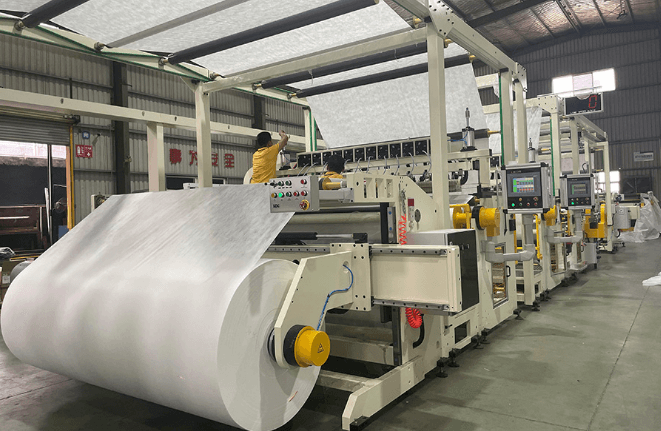

Why Filtration Automation Matters in High-Capacity Production Facilities?

Large-scale production facilities operate continuously, often processing tons of material every hour. In these environments, even a short downtime can

How filtration manufacturing equipment handles high dust load environments

High-dust-load environments are common in industries such as cement, metalworking, and power generation. In these settings, air often carries a

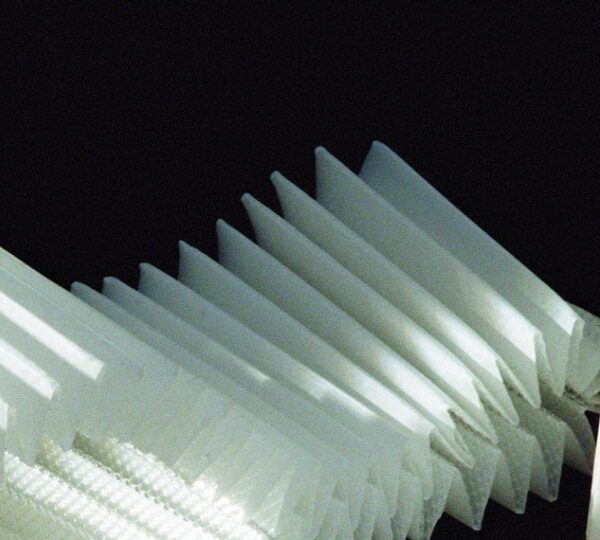

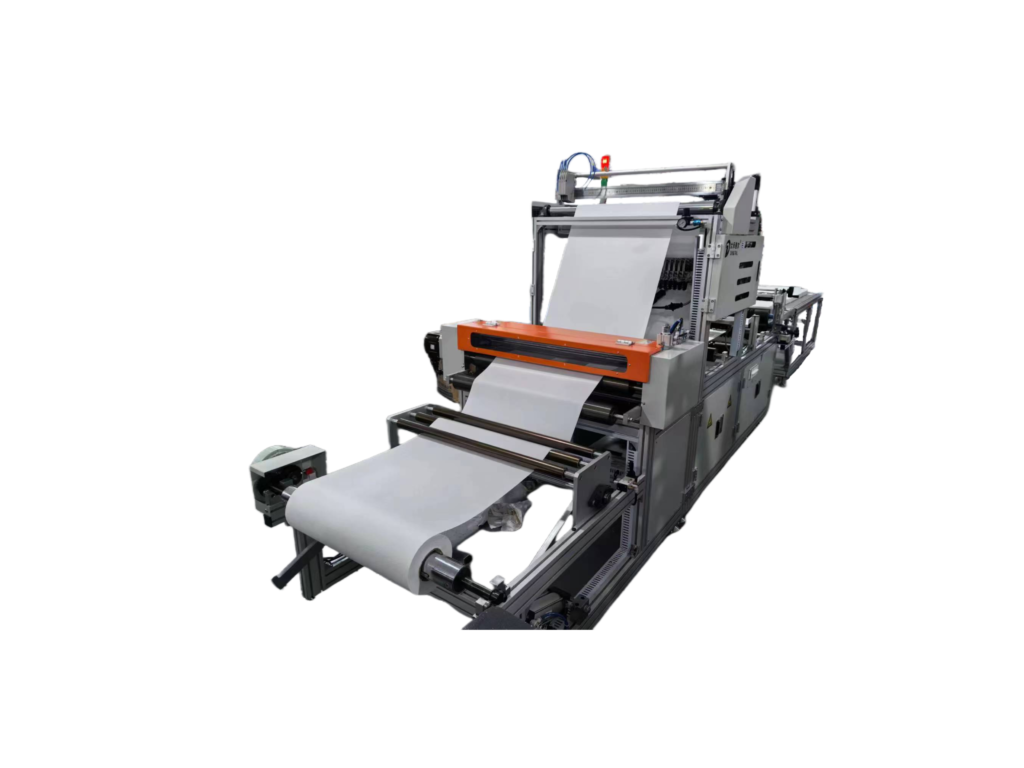

Why manufacturers choose PLC-controlled pleating equipment over traditional systems?

Manufacturers today demand absolute precision and repeatability in filter production. Traditional pleating systems often rely on mechanical adjustments, which can

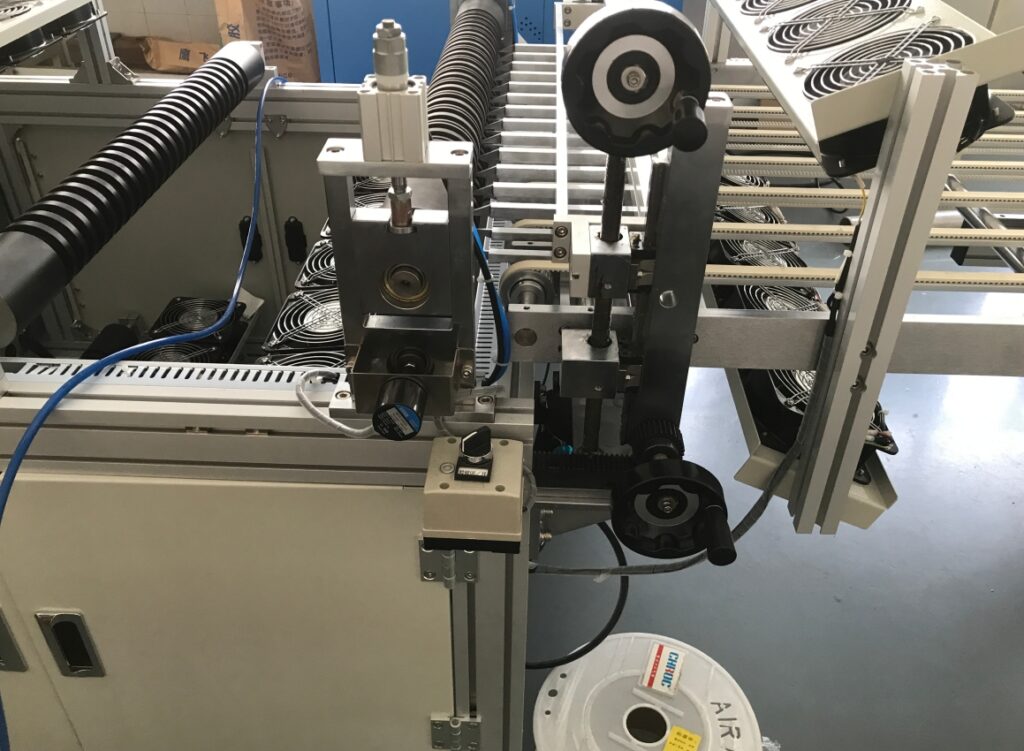

Common Problems With Filter Glue Application Machine and How to Fix Them

A Filter Glue Application Machine is a key piece of equipment in filter manufacturing for automotive, HVAC, and water purification

How Vacuum Cleaner Filter Production Equipment Ensures Consistent Filtration Quality?

Consistency in air filtration determines how effectively a vacuum cleaner performs over time. Even the most powerful motor becomes useless

How the Glue Dispensing Machine Improves Filter Assembly Speed and Accuracy?

A filter assembly demands repeatability, cleanliness, and high throughput. Manual gluing creates variation and slows lines. A Glue Dispensing Machine

How Filter Injection Technology Ensures Consistent Quality in Mass Production?

Injection-based methods have changed the way many filters are made. They let manufacturers combine precision, speed, and repeatability. Today, filter

How Pleating Machines Boost Production Efficiency for Filter Manufacturers?

Filter manufacturing has undergone significant evolution with the introduction of automation. Pleating machines have become essential in creating consistent, high-quality